Working for a more sustainable textile industry

At all stages of our products’ life cycle, we strive to use resources efficiently and sustainably, focusing on reducing waste to zero.

Thanks to our advanced recycling technology, NUREL revalorizes the nylon waste generated during the manufacturing process, converting it into a sustainable, high-performance yarn.

Reco Nylon® is a 100% recycled PA6 yarn made from pre-consumer waste.

- Reco Nylon reduces dependence on non-renewable resources

- Reduces the amount of textile waste

- Contributes to lower environmental impact

recycled nylon with less environmental impact

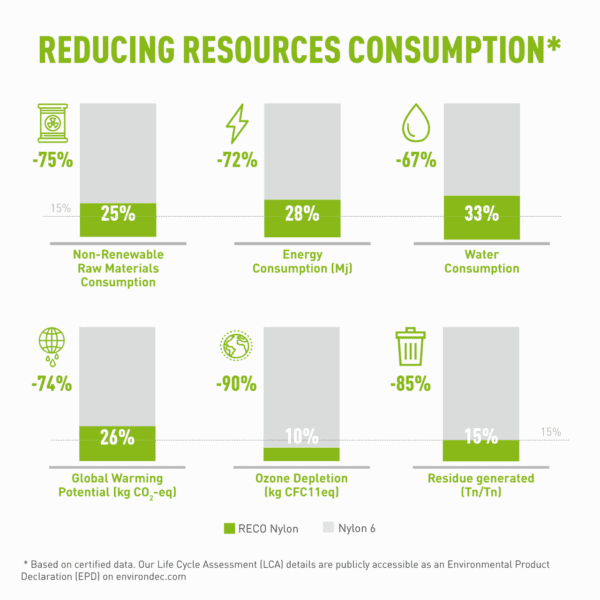

At NUREL we are involved in the study of the impact of our products through Life Cycle Analysis, with the objective of promoting sustainability in all our processes. These LCAs have allowed us to prove that Reco Nylon’s production considerably reduces the consumption of resources and minimizes its environmental impact.

The production process debold, strong, Reco Nylon is carried out entirely in our facilities, thus avoiding CO2 emissions produced during the manufacture and transportation of raw materials. Reco Nylon’s production generates approximately 9 times less CO2 pemissions than standard production.

The production of Reco Nylon 6 generates almost 9 times less CO2 emissions than standard nylon 6.

Therefore, a production of 1 ton of Reco Nylon reduces emissions of an equivalent to:

CO2 produced by 265,451 cell phones being charged

CO2 produced by a car driving 8,191 km

CO2 absorbed by 101,000 m of forest in one year

PROPERTIES and certifications

- Reco Nylon fibers offer similar quality and performance to standard yarns.

- Reco Nylon is also available in black mass.

- It is available in a wide range from 22 to 78 dtex and different formats, normal and textured.

- NUREL’s excellence in fiber production ensures optimal performance of sustainable fabrics for the sports, bath and lingerie sectors.

- For more information about the Reco Nylon product range, please contact us.

- This entire process is certified by the Global Recycled Standard (GRS) based on compliance with its fair labor and environmental impact requirements.

OUR PROCESS

We select and condition the textile waste generated at our facilities.