high barrier polymers

advanced barrier materials

Looking for a barrier packaging solution that combines high performance with real sustainability?

NUREL introduces ENOXITE BARRIER®, a range of barrier polymers designed as a sustainable and efficient alternative to traditional EVOH.

ENOXITE BARRIER® allows you to extend the shelf life of your products, thus reduce food waste and, crucially, significantly improve the recyclability of your multilayer packaging.

The perfect solution in barrier materials for packaging.

ENOXITE BARRIER® (PRODUCT RANGE): KEY BENEFITS

AVAILABLE GRADES: E20 & E30*

IMPROVED OXYGEN BARRIER PERFORMANCE:

Thanks to its barrier polymer technology, ENOXITE allows to extend the shelf life of food, guaranteeing product quality and reducing food waste.

MINIMISED ENVIRONMENTAL IMPACT:

It reduces the use of plastic in packaging, improves the recyclability of multilayer films and enables compostable barrier packaging solutions.

*Under development

ENOXITE BARRIER® E20: SUSTAINABLE ADVANTAGES

WATER-SOLUBLE

ENOXITE® E20 and E30 are advanced polymers soluble in water at room temperature. Their water solubility enables seamless removal during recycling, without the need for elevated temperatures, simplifying recovery and minimizing energy use across the process.

RECYCLABLE MULTILAYER BARRIER FILM

The ENOXITE® E20 grade is specifically engineered to dissolve completely during the washing stage of standard recycling systems – regardless of water temperature. This allows for easy separation in multilayer barrier films, enhancing recyclate purity and boosting the overall efficiency and circularity of the recycling stream.

BIODEGRADABILITY

ENOXITE® E20 is certified as OK biodegradable WATER by TÜV AUSTRIA. After dissolving in water during the recycling process, the polymer undergoes complete biodegradation, leaving no persistent residues and ensuring minimal environmental impact.

FOOD WASTE REDUCTION

Thanks to its excellent oxygen and moisture barrier properties, ENOXITE® E20 helps extend the shelf life of packaged food. This directly contributes to reducing food spoilage and waste, while lowering the environmental footprint across the supply chain.

ENOXITE E20 - CERTICADO COMO OK biodegradable WATER por TÜV AUSTRIA

Our ENOXITE® E20 grade is certified OK biodegradable WATER by TÜV AUSTRIA.

The biodegradation of ENOXITE® E20 occurs subsequent to its dissolution in water during the recycling procedure, ensuring that no harmful residues remain.

This certification confirms its environmental safety, making it ideal for sustainable packaging solutions aligned with circular economy goals.

SUSTAINABLE ALTERNATIVE TO EVOH

Multilayer packaging is essential to protect products, but often compromises recyclability due to barrier materials such as EVOH.

ENOXITE® BARRIER E20 is ideal for those looking for an alternative to EVOH, solving the problem of the difficulty of recycling multilayer films with EVOH.

With a clear focus on circular economy, ENOXITE E20 is positioned as an EVOH recycling solution.

ENOXITE BARRIER® E20 - TECHNICAL FEATURES

HIGH BARRIER

Alternative to EVOH. Preserves the freshness and quality of food over long storage periods. OTR is dependent on ambient moisture.

E20 provides excellent performance in low humidity environments.

COMPLIANCE WITH FOOD CONTACT REGULATIONS

Enoxite Barrier E20 can be used for indirect food contact* depending on the type of food, duration and conditions, in accordance with Regulation (EU) No 10/2011.

*Complies with food contact regulations when used as an inner layer.

COMPATIBILITY

Suitable for use in multi-layer structures, combined with conventional polymers (PP, PE, PS, PET, PA) and biopolymers.

PROCESSING

Compatible with blown cast and three-bubble extrusion methods, as well as blow moulding, using standard EVOH processing equipment.

No tie layer required when combined with biopolymers (discover NUREL’s INZEA biopolymers).

SUSTAINABLE BARRIER MATERIALS FOR COMPOSTABLE PACKAGING

By combining NUREL’s expertise in INZEA® compostable biopolymers with ENOXITE® Barrier, we create compostable packaging structures with excellent barrier properties, without the need for a tie layer. This simplifies multilayer design and offers a truly sustainable alternative to conventional materials.

We help you meet market demands and future regulations (such as the EU Packaging Regulation PPWR) by offering a solution that truly improves the recyclability of multilayer films.

ENOXITE BARRIER® E20: MAIN APPLICATIONS

PACKAGING FOR DRY AND BAKED FOODS

ENOXITE® E20 is ideal for the packaging of dry food products such as nuts, dried fruits, dehydrated foods, cereals, rice, pasta, pulses and bakery products due to its excellent oxygen barrier performance in low moisture environments.

It can be used as a barrier material in various packaging formats such as flexible films, thermoformed trays or pouches.

THERMOFORMED TRAYS

POUCHES

FLOW PACKS

BARRIER CONTAINERS

ENOXITE® E20 is ideal for chemical-contact packaging thanks to its excellent grease resistance and oxygen barrier. It’s perfectly suited for demanding applications such as agrochemical and cosmetic packaging.

Thanks to its high grease resistance, ENOXITE® E20 enables asymmetric packaging structures where it can be in direct contact with the product, ensuring protection and performance without additional layers.

AGROCHEMICAL CONTAINERS

COSMETIC CONTAINERS

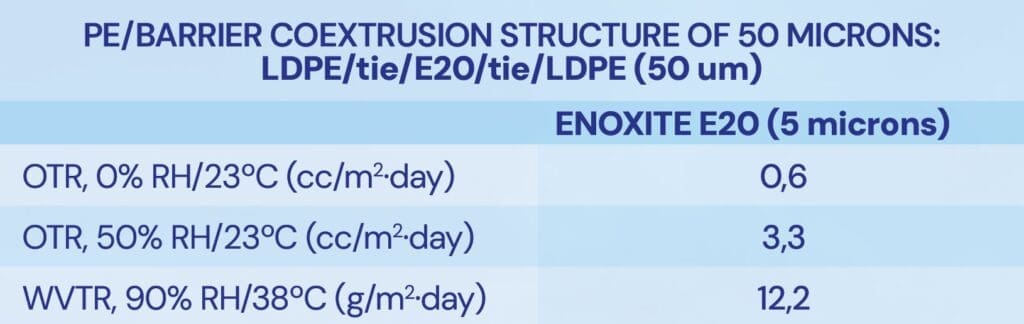

ENOXITE BARRIER® E20 - OTR PERFORMANCE

FREQUENTLY ASKED QUESTIONS

ENOXITE® BARRIER provides an excellent oxygen barrier performance, particularly in low-moisture environments. For example, in a 100-micron LDPE coextrusion structure, a 5-micron layer of ENOXITE® E20 can achieve an OTR of 0.6 cc/m2⋅day at 0% RH and 23°C.

ENOXITE® Barrier E20 can be used for indirect food contact in accordance with Regulation (EU) No. 10/2011, depending on the type of food, duration, and conditions. It is food contact compliant when used as an internal layer.

ENOXITE BARRIER grades are compatible for use in multilayer structures with conventional polymers such as PP, PE, PS, PET, PA, as well as with biopolymers. In fact, a tie layer is not required when it is combined with biopolymers. Discover INZEA, NUREL’s biopolymers solution.

No. It is compatible with standard EVOH processing equipment, including Blown, Cast, and Three Bubble extrusion, as well as Blow Moulding.