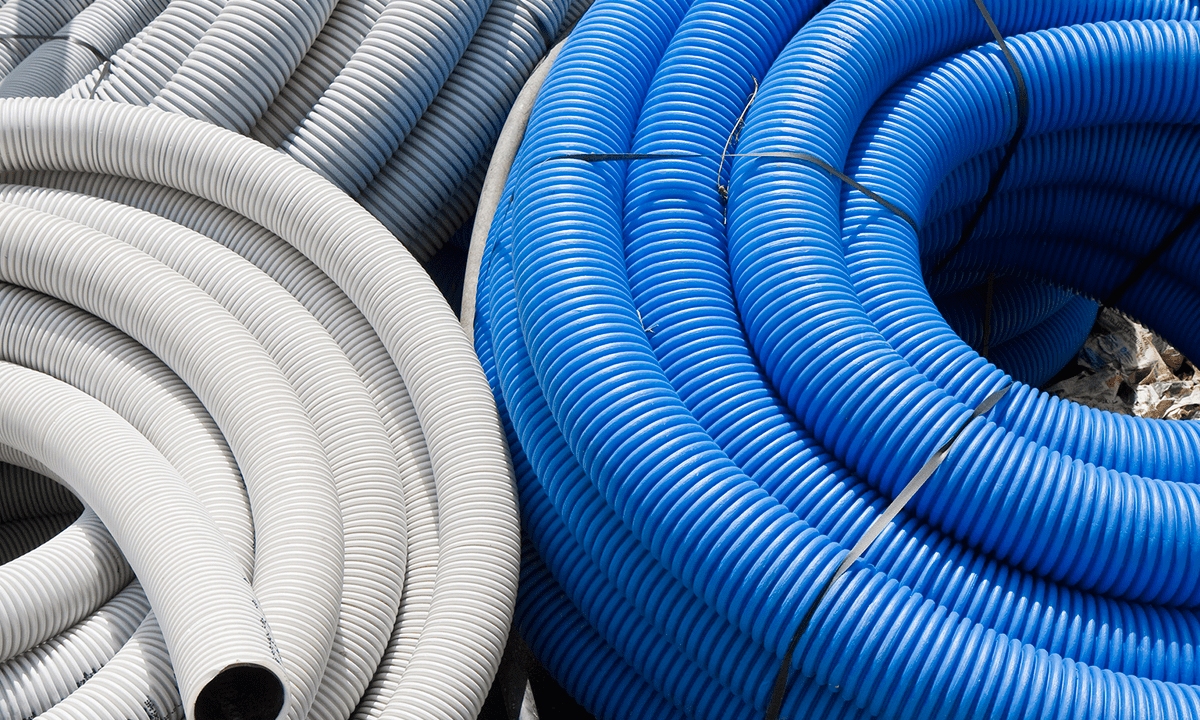

High viscosity polyamide for corrugated tubes and flexible pipes

Corrugated tubes made from polyamide are versatile and durable components used in various applications in the automotive and other industries and require flexibility, strength, and of course durability. Both small and large diameter tubes are produced by corrugated extrusion.

Thanks to the use of our range of Promyde high viscosity PA grades for flexible pipes extrusion, these driving systems will benefit from long-term heat resistance, chemical resistance, flame retardancy and even added flexibility.

PA6 FLAME RESISTANT V0 AND HL3 FOR RAILWAYS ACCORDING TO UNE 45545

Many applications for corrugated pipes require flame retardant material properties. Both Promyde B40 P2 U0 and Promyde B40 P2 U0 UV HS are UL94 certified, making them suitable for V0-rated conduits.

With a high Limiting Oxygen Index (LOI) content of 32-33%, Promyde B40 P2 U0 and Promyde B40 P2 U0 UV HS also comply with HL3 standards according to UNE 45545. These materials are ideal for use in trains, railways, underground systems, and metro systems.

HIGH PERFORMANCE IN THE MOST CHALLENGING ENVIRONMENTS

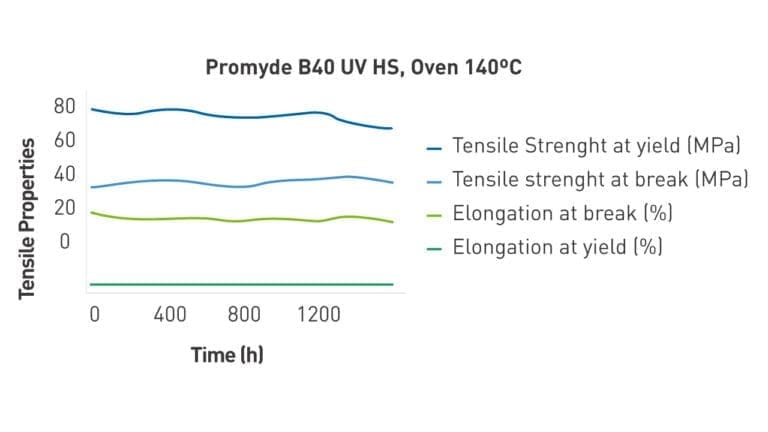

- Thermal and Long-Term Stability: Corrugated pipes manufactured with Promyde 6 B40 L UV HS maintain their structural integrity and mechanical properties over time, even over a wide temperature range. This makes them suitable for applications in environments with temperature fluctuations, in compliance with UL1660 standards.

- Mechanical and Abrasion Resistance: Our PA grades for corrugated pipe extrusion offer high mechanical and abrasion resistance, ensuring that corrugated pipes can withstand stress, compression and bending without damage. This provides protection against wear and friction.

- Chemical Resistance: Promyde PA6 extrusion grades offer resistance to a wide range of chemicals, enabling the corrugated tubes to transport corrosive liquids, oils, or gases without deteriorating.

- For Extra Flexible Piping Requirements: Promyde B40 P2 FLX FC, with a low modulus of 500 MPa, is recommended for highly flexible piping needs. It complies with food contact regulations and is ideal for coating metal pipes in food and beverage production.

HIGH PERFORMANCE IN THE MOST CHALLENGING ENVIRONMENTS

- Thermal and Long-Term Stability: Corrugated pipes manufactured with Promyde 6 B40 L UV HS maintain their structural integrity and mechanical properties over time, even over a wide temperature range. This makes them suitable for applications in environments with temperature fluctuations, in compliance with UL1660 standards.

- Mechanical and Abrasion Resistance: Our PA grades for corrugated pipe extrusion offer high mechanical and abrasion resistance, ensuring that corrugated pipes can withstand stress, compression and bending without damage. This provides protection against wear and friction.

- Chemical Resistance: Promyde PA6 extrusion grades offer resistance to a wide range of chemicals, enabling the corrugated tubes to transport corrosive liquids, oils, or gases without deteriorating.

- For Extra Flexible Piping Requirements: Promyde B40 P2 FLX FC, with a low modulus of 500 MPa, is recommended for highly flexible piping needs. It complies with food contact regulations and is ideal for coating metal pipes in food and beverage production.

MAIN APPLICATIONS OF PROMYDE CORRUGATED TUBES

Polyamide corrugated tubes are used to protect electrical and communication cables and conduits from mechanical damage, abrasion, and environmental factors. Additionally, thanks to their good chemical resistance and thermal stability, they are used for conducting refrigerant in cooling and air conditioning systems, as well as for fluid conveyance in the automotive industry.

Download our catalogues

Promyde - Extrusion

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter