PA 6 with UV resistance

UV degradation process starts with the absorption of sunlight by the polymer. This energy source can break polymer chains, resulting in a drop in mechanical properties, such as loss of strength, impact resistance and flexibility, and undesirable color changes, including yellowing, loss of gloss and loss of color saturation.

Thanks to its vertical integration from polymerization, NUREL has developed a wide range of UV-resistant polymers by modifying their polymer chains and adding highly effective additives.

From this complete development, the additives incorporated into the polymer matrix are capable of absorbing part of the solar radiation that strikes the polymer, thus preventing this excess energy from breaking the polymer chains.

Polyamide solutions with UV Protection

NUREL’s UV-resistant polymers have a triple protective function, thus providing the highest possible UV protection.

- First, the additive package absorbs sunlight energy to prevent degradation of the polymer chains.

- Moreover, the additive package captures free radicals to prevent unwanted effects and endless chain-breaking reactions.

- Finally, the modification of the polymer chains helps to increase their stability and resistance to solar radiation.

APPLICATIONS AND USES OF POLYAMIDE WITH UV PROTECTION

This UV protection system can be applied to the wide variety of polymeric solutions offered by NUREL:

- When exposed to solar radiation: non-reinforced polymers, polymers reinforced with different percentages and fillers, flame retardant solutions.

- Outdoor applications where functionality and aesthetics are very important.

Applications

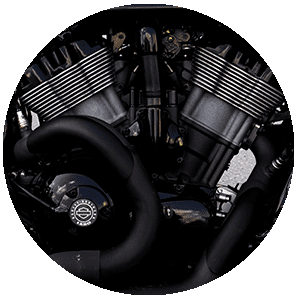

Vehicle exterior and headlights

Vehicle exteriors require unique solutions, such as UV resistance and surface finish. NUREL's polyamide compounds offer unique performance in terms of strength and durability, remaining unalterable for a longer period of time.

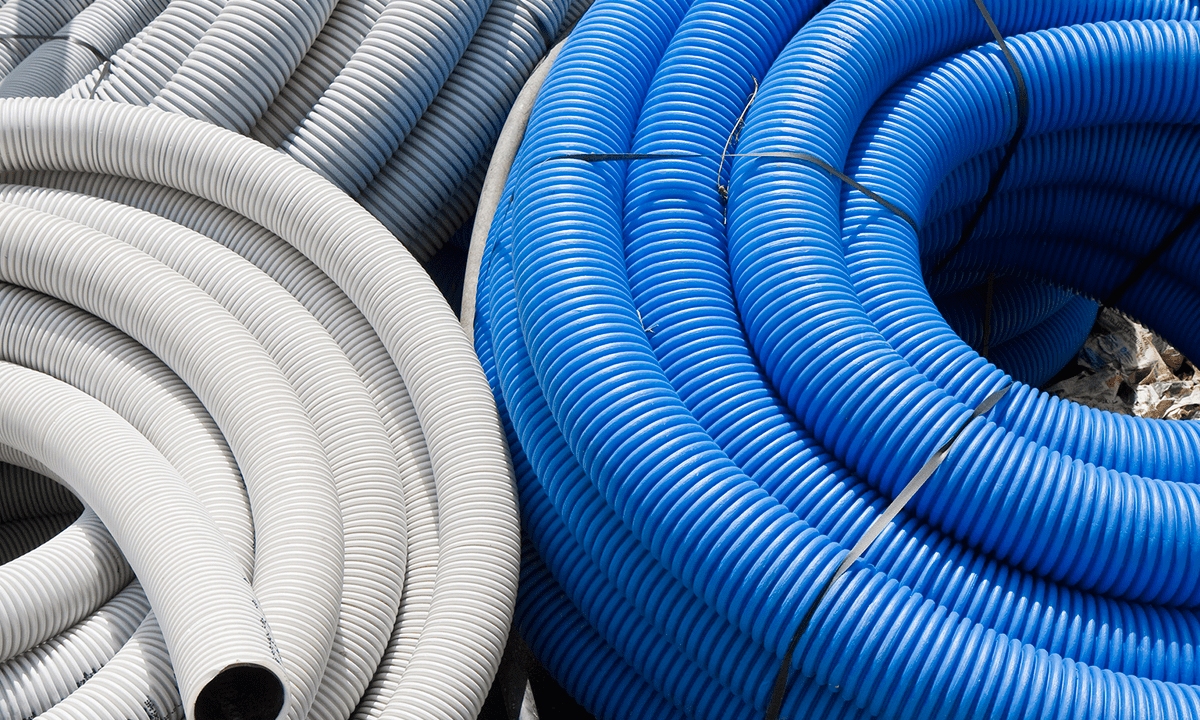

Corrugated pipes

Promyde B33 is commonly used for corrugated pipes of this diameter, and Promyde B36 and B38 for larger diameters.

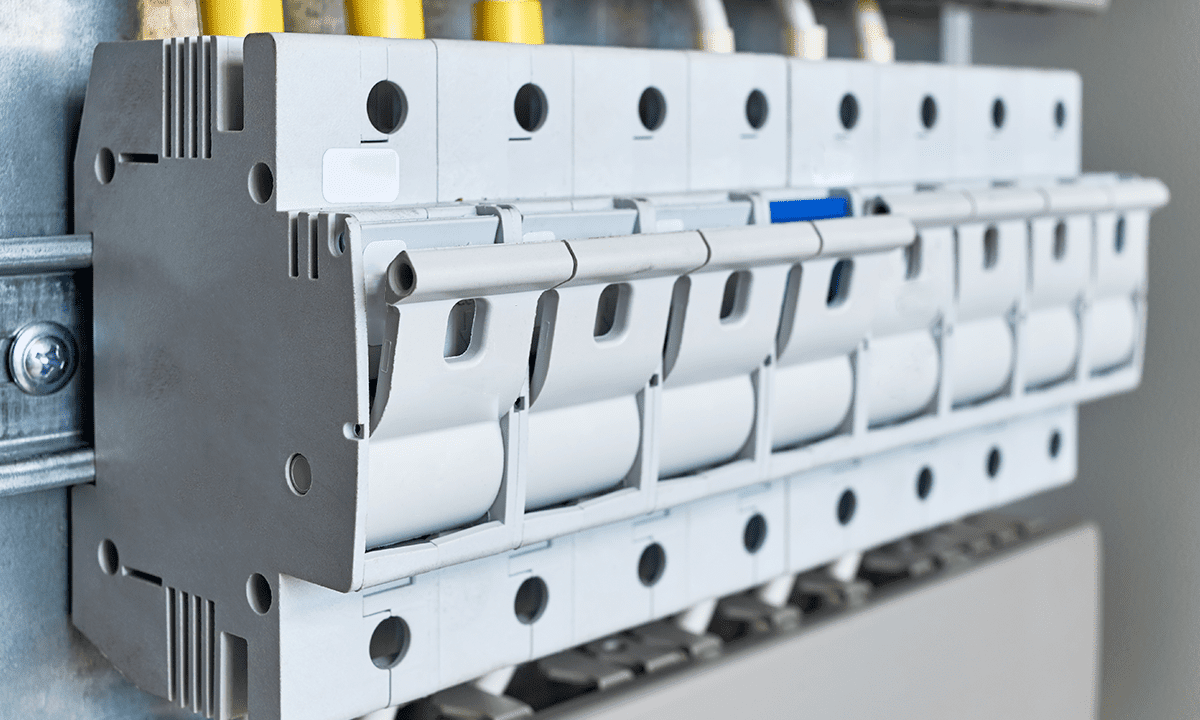

Electrical components

Electrical components must meet high requirements including high temperature resistance, dimensional stability and chemical resistance. This type of parts uses PA, PBT, PP and PP compounds. These materials ensure optimum and safe performance in electrical applications.

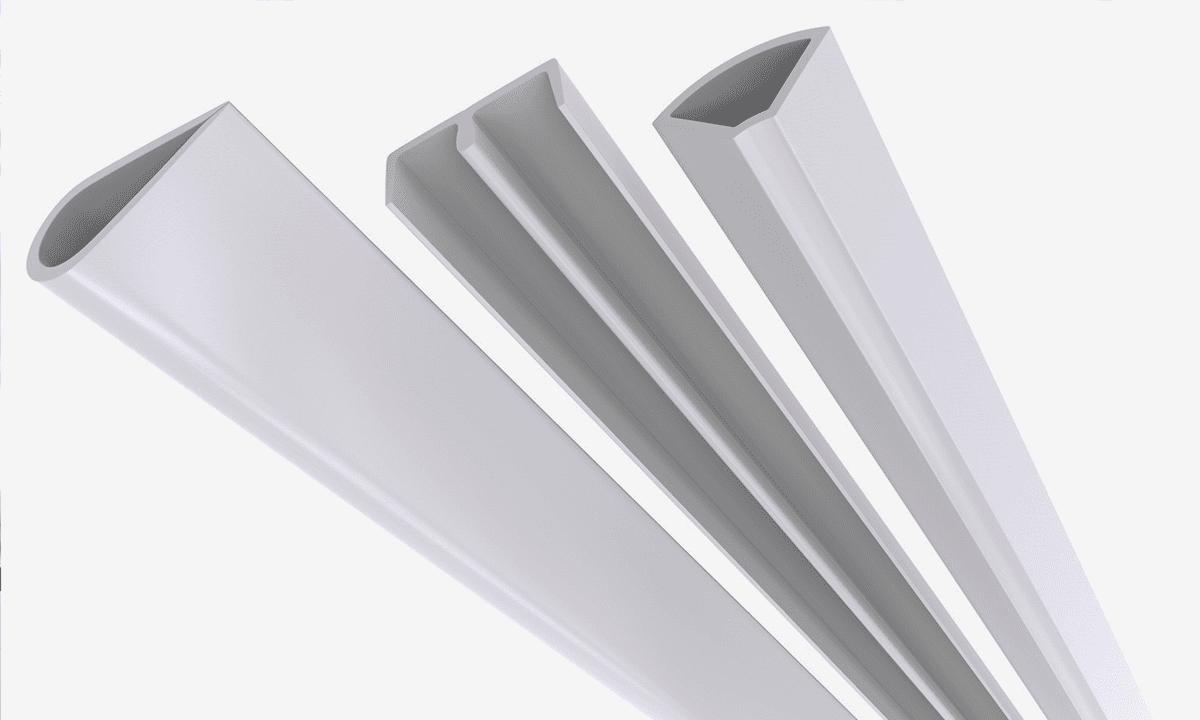

Sheets, bars and profiles

Used as components for industrial machinery and equipment, Promyde® polyamide 6 is the material of choice for leading producers in the extrusion of semi-finished products and solid bars for machining.

RELATED MARKETS

MOBILITY AND AUTOMOTIVE

The mobility sector has always been a leader in mechanical innovation and process optimization. At NUREL, we support this evolution with our range of engineering polymers - PA6, PA66, PBT, PET and PP - designed to respond to the industry's demand for lighter, more sustainable and efficient solutions.

INDUSTRIAL

The industrial sector demands high-performance materials to meet stringent standards of efficiency, durability and strength. Our range of engineering polymers and recycled technical composites offer high-value solutions for the manufacture of industrial machinery and precision components.

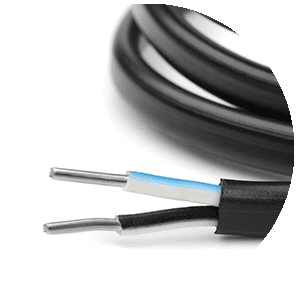

Cables and Pipes

Promyde® PA and Proxylene® PBT polymers for UL 83-certified cables such as copper building wire, PVC Nylon tray cable, THHN cable and THWN cable, fiber optic cable, as well as tubes and pipes for cable management systems.

OTHERS SOLUTIONS

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter