high-viscosity

PA6 and PBT high vicosity compounds

NUREL offers a broad range of high-viscosity grades of polyamide 6 (PA6) and polybutylene terephthalate (PBT) specifically formulated for various extrusion applications. These polymer grades are well-suited for the production of tubes, tanks, conduits, cable coatings, profiles, and filaments.

The extensive selection of high-viscosity grades allows NUREL to incorporate additional properties into their products, enhancing thermal protection, ultraviolet radiation resistance, and fire protection. This ensures that the materials meet the specific requirements of each application and deliver optimal performance in challenging environments.

Promyde® polyamide 6 high viscosity grades for extrusion

NUREL’s expertise positions it as a reliable supplier of polyamide 6 in the global extrusion market. Its presence spans multiple segments, including high tenacity yarns, profiles, pipes, extrusion blow molding, and cable jacketing. The modification of polymer chains during polymerization, along with the unique additive packages offered, forms our extensive Promyde extrusion portfolio.

Promyde PA6 high viscosity range, includes products with viscosities of up to 5.0, making them particularly suitable for blow molding applications such as the production of large tanks and containers. These products guarantee excellent mechanical strength and durability, meeting the demanding requirements for strength and performance.

Promyde for extrusion range offers various solutions for different applications, ranging from relative viscosities of 3.0 to 5.0. It includes impact-modified PA, glass fiber-reinforced grades, flame retardant formulations, and high-flexibility developments. Additionally, UV protection and heat stabilizers are available to enhance the lifespan of outdoor applications like electrical conduits.

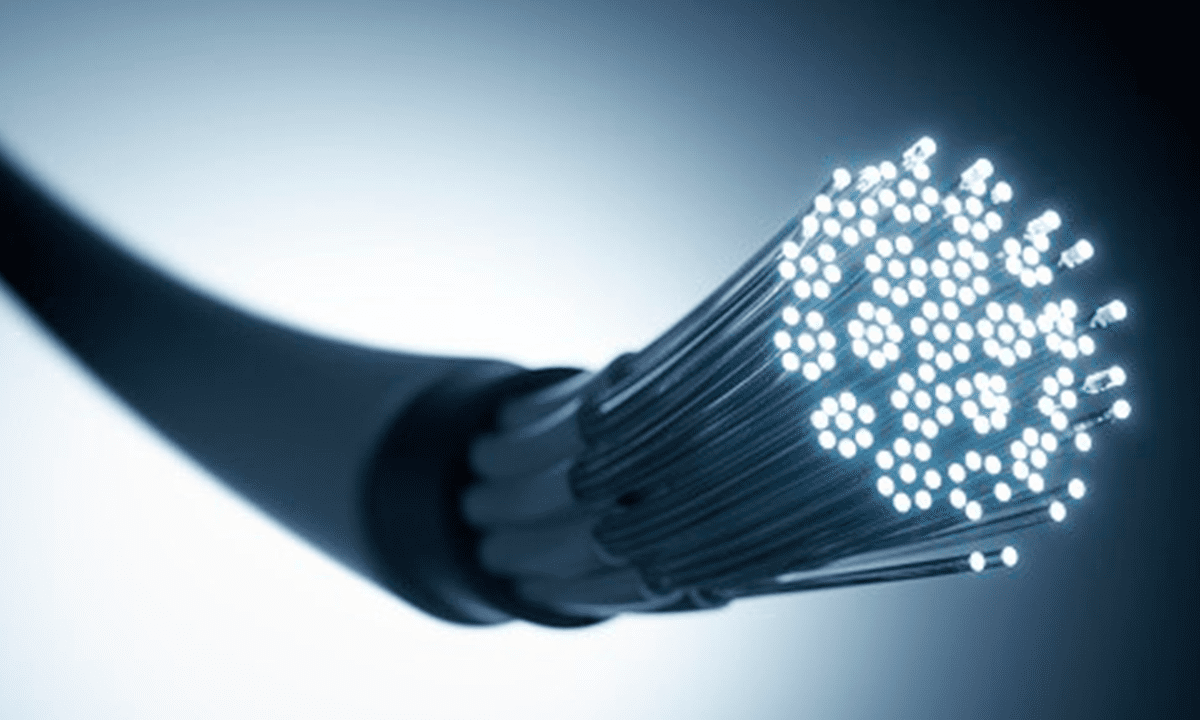

Proxylene high viscosity PBT for optical fiber cable

NUREL introduces a new portfolio of high-viscosity unreinforced PBT grades, specifically designed for extrusion applications. This portfolio includes grades with improved hydrolysis resistance.

One of the primary applications for high-viscosity PBT grades is the manufacturing of optical fibers using extrusion processes. PBT Proxylene extrusion grades offer excellent thermal stability, low attenuation and high transmission properties, making them an ideal material for producing high quality optical fibers used in telecommunications and data transmission.

Pipes and tubes produced with Proxylene PBT HR grades benefit from good chemical resistance, dimensional stability and mechanical strength. They also exhibit exceptional resistance to damage caused by water at high temperatures. These characteristics of PBT Proxylene enable the production of durable and reliable pipes used in industries such as plumbing, irrigation and automotive fluid systems.

Proxylene high viscosity PBT for optical fiber cable

NUREL introduces a new portfolio of high-viscosity unreinforced PBT grades, specifically designed for extrusion applications. This portfolio includes grades with improved hydrolysis resistance.

One of the primary applications for high-viscosity PBT grades is the manufacturing of optical fibers using extrusion processes. PBT Proxylene extrusion grades offer excellent thermal stability, low attenuation and high transmission properties, making them an ideal material for producing high quality optical fibers used in telecommunications and data transmission.

Pipes and tubes produced with Proxylene PBT HR grades benefit from good chemical resistance, dimensional stability and mechanical strength. They also exhibit exceptional resistance to damage caused by water at high temperatures. These characteristics of PBT Proxylene enable the production of durable and reliable pipes used in industries such as plumbing, irrigation and automotive fluid systems.

Applications

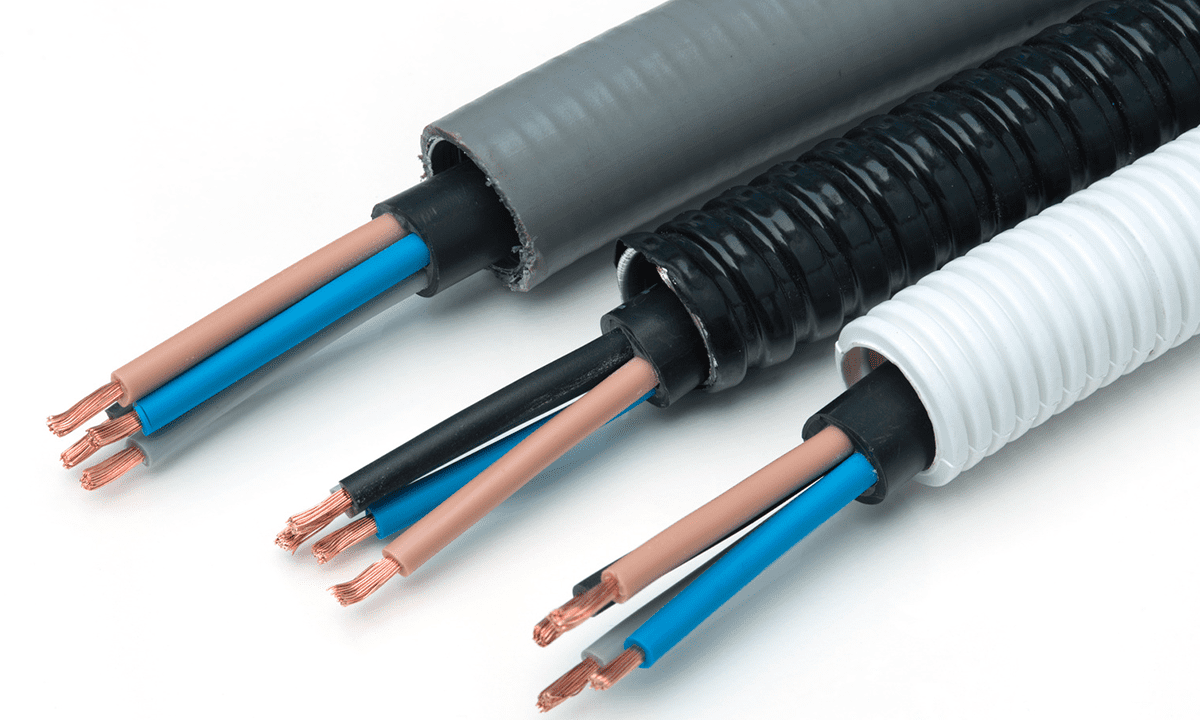

Cable jacketing

At NUREL, we provide heat-resistant, UV-stable and even flame-retardant polyamide and PBT compounds for the production of cables, wires and cable protection.

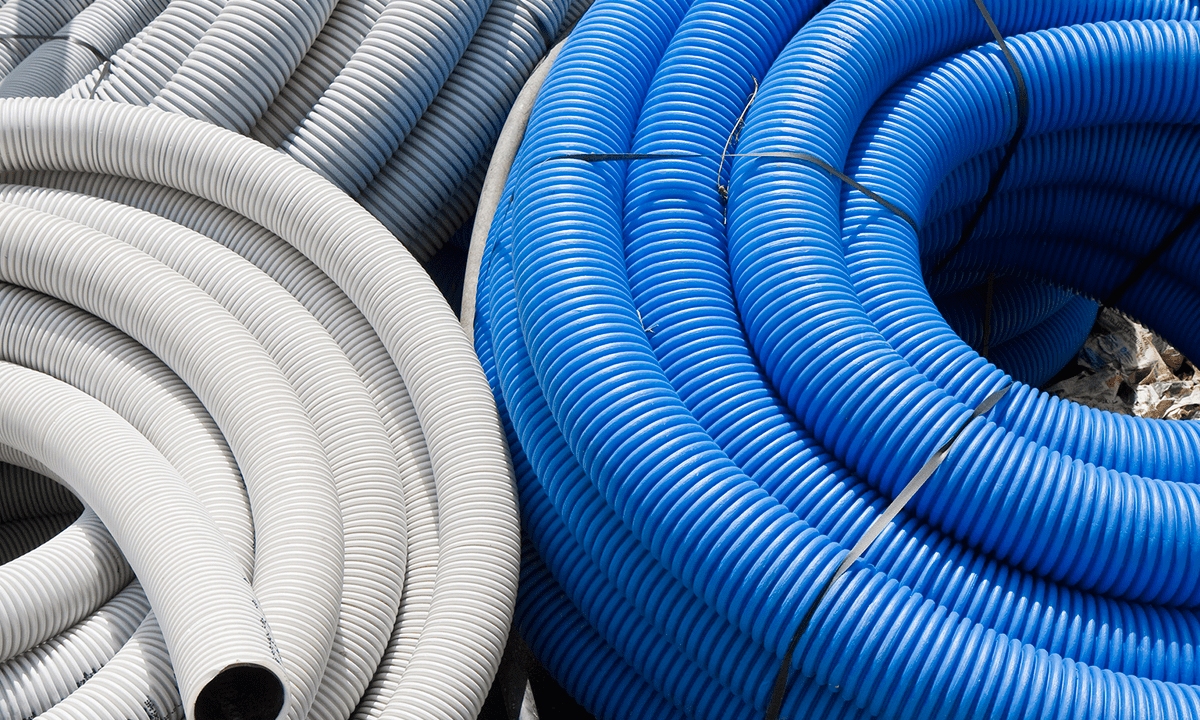

Corrugated pipes

Promyde B33 is commonly used for corrugated pipes of this diameter, and Promyde B36 and B38 for larger diameters.

Optical fiber cable

Optical fiber cables are crucial in modern telecommunications. NUREL has developed a specific range of Proxylene (PBT) to reinforce and protect the delicate optical fibers within the cable. We also offer special grades of Promyde PA6 for optical fiber cables with high impact resistance requirements.

Monofilaments

Promyde® and Proxylene range includes high and medium viscosity grades for monofilament extrusion and specialty grades with improved transparency and flexibility.

TANKS AND RESERVOIRS

Promyde PA6 blown extrusion grades with a viscosity of 5.0 provide improved mechanical properties and increased flow resistance in the molten state.

Sheets, bars and profiles

Used as components for industrial machinery and equipment, Promyde® polyamide 6 is the material of choice for leading producers in the extrusion of semi-finished products and solid bars for machining.

RELATED MARKETS

INDUSTRIAL

The industrial sector demands high-performance materials to meet stringent standards of efficiency, durability and strength. Our range of engineering polymers and recycled technical composites offer high-value solutions for the manufacture of industrial machinery and precision components.

Cables and Pipes

Promyde® PA and Proxylene® PBT polymers for UL 83-certified cables such as copper building wire, PVC Nylon tray cable, THHN cable and THWN cable, fiber optic cable, as well as tubes and pipes for cable management systems.

Filaments

NUREL offers a wide range of polyamide 6 homopolymers and copolyamides for monofilament applications such as guides for viticulture, fishing nets, cutting lines in lawn mowers, hot melt filaments for adhesives in sportswear and clothing, filaments for 3D printing, etc.

OTHERS SOLUTIONS

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter