TECHNICAL POLYMERS FOR 3D PRINTING FILAMENTS

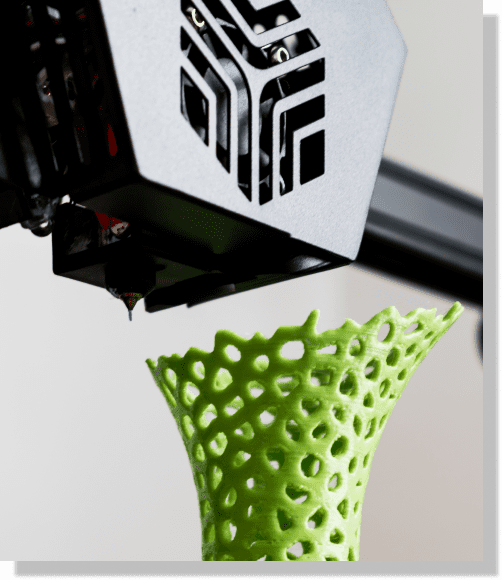

NUREL’s 3D printing polymers, such as polyamides, PET-G, PLA and biopolymers, are designed to offer excellent interlayer adhesion, low moisture absorption, high mechanical properties, dimensional stability and ease of processing, making them the ideal choice for technical and complex applications in a variety of industries.

3D printing is an established technology that can replace traditional can replace traditional production methods for a wide range of industrial products.. The demand for these products is increasing, and so is the need for develop high-value technical solutions. For this reason, NUREL has developed a comprehensive range of technical materials specifically for 3D printing applications.

Advanced 3D printing offers a cost-effective production method, suitable not only for small-scale manufacturing, but also for large-scale industrial production. Polyamides, PETG, PLA and biopolymers are essential for producing high-performance parts in FDM processes.

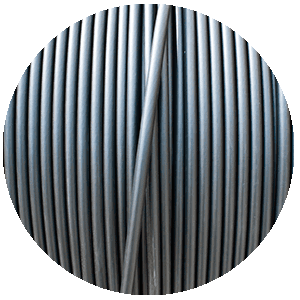

OUR POLYMERS FOR 3D PRINTING

NUREL offers a wide range of polymers for 3D printing filament extrusion, providing diverse options for the most specialized and demanding applications.

This product line includes PA compounds , PET-G, PLA, as well as biopolymers and water-soluble polymers.

PROMYDE® FOR 3D PRINTING FILAMENTS

POLYAMIDES FOR 3D PRINTING

NUREL has developed PA6-based copolyamides specifically for 3D printing applications. These materials combine the exceptional mechanical properties of PA6 with optimal printing conditions and excellent processing.

Our copolyamides are designed to adjust the crystallinity and reduce the melting point below 220°C, which simplifies the printing process and improves part quality.

Promyde® copolyamides offer improved interlayer adhesion and allow printing without a heated bed, while reducing moisture absorption, warping and shrinkage typical of standard PA6.

PURE POLYAMIDES

PROMYDE B730

NOT REINFORCED

GLASS FIBER AND CARBON FIBER REINFORCED POLYAMIDES

PROMYDE B930 P2 G30 S2

REINFORCED FV

PROMYDE B930 P2 CF15S

REINFORCED FC

PROXYLENE® FOR 3D PRINTING FILAMENTS

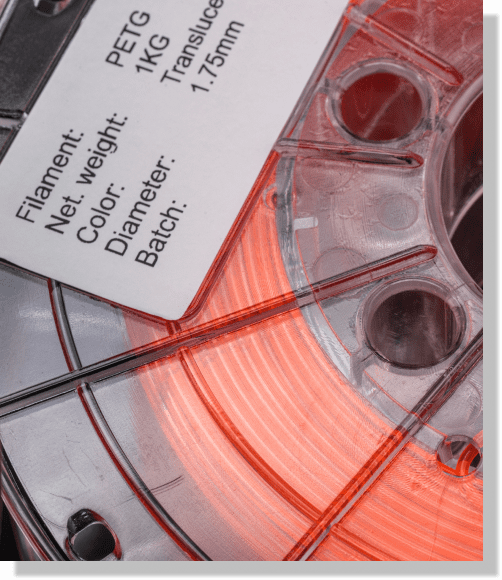

PET-G FOR 3D PRINTING

PET-G is a very popular material for 3D printing, due to its versatility, strong adhesion and minimal deformation, ensuring high quality results.

Proxylene® PET-G combines the strength and durability of ABS with the ease of use of PLA, making it an ideal choice for functional parts and prototypes. Its strength and shock absorbency, along with good flexibility, reduce the likelihood of printed parts breaking under stress.

With a higher glass transition temperature of around 80°C, PET-G can withstand elevated temperatures without deformation. This makes it a suitable choice for applications requiring exposure to high temperatures.

PURE POLYAMIDES

PROXYLENE

A95G

UNCOATED

GLASS FIBER AND CARBON FIBER REINFORCED POLYAMIDES

PROXYLENE A95G P2 CF10S A95G P2 CF15S

REINFORCED FV

PROXYLENE A95G P2 G30 S2

REFROZEN FC

PLA FOR 3D PRINTING

Proxylene® PLA with up to 15% carbon fiber reinforcement is an ideal choice for 3D printing due to its stiffness, strength and dimensional stability. This material is perfect for lightweight, durable parts with high-resolution prints and excellent strong adhesion to the base and between layers.

Carbon fiber reinforcement makes Proxylene PLA CF suitable for functional prototypes, end-use parts and automotive components that require mechanical strength and low weight. With its lower environmental impact and low shrinkage, it is an excellent choice for sustainable projects that require precision and performance.

CARBON FIBER REINFORCED PLATE

PROXYLENE X5 P2 CF10S

REINFORCED 10% FC

PROXYLENE X5 P2 CF15S

REINFORCED 15% FC

inzea® FOR 3D PRINTING FILAMENTS

COMPOSTABLE BIOMATERIALS FOR 3D PRINTING

NUREL’s INZEA® biopolymers for 3D printing filaments offer a compostable and biodegradable bio-based solution ideal for a variety of 3D printing applications.

Parts printed with INZEA® biopolymers offer significant mechanical advantages over PLA, including improved adhesion, flexibility, impact resistance and, for HTS grades, increased thermal resistance.

BIODEGRADABLE

INZEA F58

FLEXIBLE HEAT RESISTANCE

F2 HTS 451

VERSATILE HEAT RESISTANCE

F2 HTS 090

HIGH HEAT RESISTANCE

ENOXITE WATER® FOR 3D PRINTING FILAMENTS

Soluble polymers for 3d printing of complex geometries

Nurel Enoxite Water® water-soluble polymers are the ideal support material for 3D printing, allowing the creation of complex geometries and overhangs with ease of removal.

They easly biodegrade in cold water, leaving the final object completely clean and residue-free, and are certified OK biodegradable WATER by TÜV AUSTRIA.

WATER-SOLUBLE MATERIALS

ENOXITE WATER W10

BIODEGRADABLE & WATER-SOLUBLE

Download our catalogues

MARKETS

Filaments

SOLUTIONS

To be specified

To be specified

To be specified

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter