NEW COPOLYAMIDES FOR ASYMMETRICAL MULTILAYER FILM

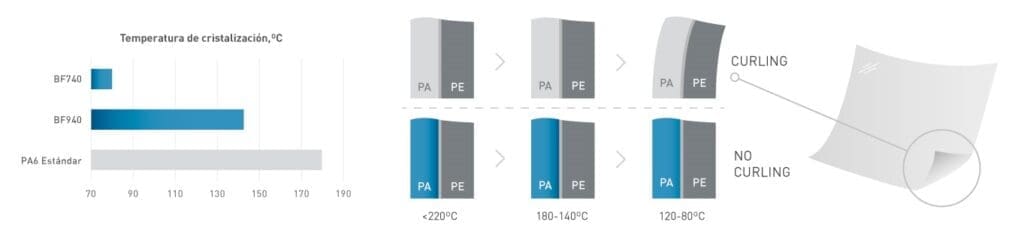

Curling is a common problem in asymmetrical PA/PE film extrusions used for manufacturing vacuum bags and container lids. Curled films have difficulty being properly wound, printed, or thermoformed.

The curling issues arise from a solidification temperature difference between polyamide (PA) and polyethylene (PE). This problem can be mitigated with our range of copolyamides for asymmetrical multilayer structures.

Promyde® BF940 is an alternative to PA 6/66. It is a copolyamide with low crystallization speed, which helps prevent curling issues, making it the perfect solution for asymmetrical structures.

Promyde® BF940 also offers higher transparency than conventional polyamides available on the market, even after pasteurization and sterilization processes.

This property, combined with the inherent gloss of polyamide, makes it the ideal material for visually attractive consumer packaging.

Variety of promyde copolyamides

Additionally, NUREL offers a new range of copolyamides such as Promyde® BF642, BF740, and BF840, which also achieve low curling and high transparency.

ADVANTAGES OF PROMYDE FOR LOW CURLING FILMS

By using our Promyde® copolyamides in the production of PA/PE multilayer films, the solidification temperature difference is minimized, significantly reducing the occurrence of curling. This ensures that these structures can be efficiently processed, precisely printed, and smoothly thermoformed, resulting in high-quality final products.

ADVANTAGES OF PROMYDE FOR LOW CURLING FILMS

By using our Promyde copolyamides in the production of PA/PE multilayer films, the temperature solidification difference is minimized, reducing the occurrence of curling. This ensures that these structures can be efficiently processed, accurately printed, and thermoformed smoothly, resulting in high-quality final products.

Download our catalogues

Promyde - Film

Applications

Meat and bone-in meat packaging

Packaging for sharp-edged foods requires high puncture resistance, flexibility, moisture barrier, transparency, and an attractive gloss. NUREL offers a range of special copolyamides and polymers with high oxygen barrier properties for the manufacturing of vacuum bags and thermoformed packaging for meat.

Skin Packaging

Skin packaging is gaining popularity due to its lightweight and visually appealing design, as well as its superior technical performance. NUREL provides specially formulated copolyamides that exhibit exceptional strength, sealing capabilities, barrier properties, and unmatched glossiness.

Stand-up pouches

NUREL offers a complete range of Polyamide 6, Copolyamides and Ultra-High barrier materials for Doypacks. PA-based film materials not only help extend the shelf life of packaged food but also contribute to reducing plastic usage. Promyde polyamides offer excellent mechanical and barrier properties while providing an appealing packaging finish, thanks to their glossy appearance.

Cheese packaging

Cheese packaging is essential to guarantee the quality, safety, and freshness of the product. It must meet a series of requirements to protect the cheese from oxidation, dehydration, and preserve its maturation process. NUREL offers solutions that adapt to these requirements by providing packaging with barrier properties and oxygen permeability.

Deep thermoforming

NUREL offers a wide selection of polyamides and copolyamides designed for deep thermoforming packaging, with a focus on providing superior barrier properties and puncture resistance to effectively extend the shelf life of food products, thus contributing to the reduction of food waste. This type of packaging is particularly suitable for the preservation of large portions of fresh meat and whole cheeses.

RELATED MARKETS

Packaging

Polyamides are used in the packaging industry for their good mechanical properties, barrier properties and for providing a quality finish due to their high gloss and transparency.

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter