PROMYDE®: POLYAMIDES WITH ANTIOXIDANT AND ANTIMICROBIAL PROPERTIES

NUREL’s latest innovation in the packaging industry extends the shelf life of packaged food.

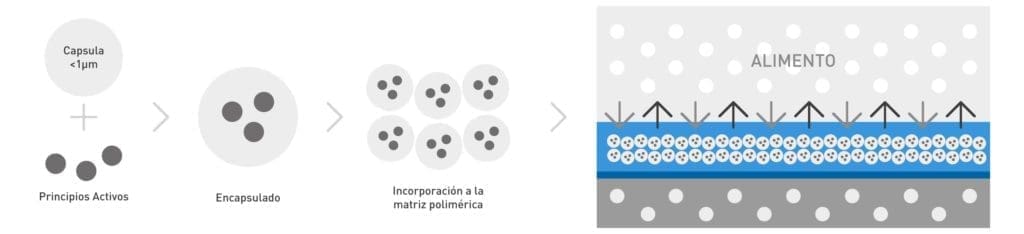

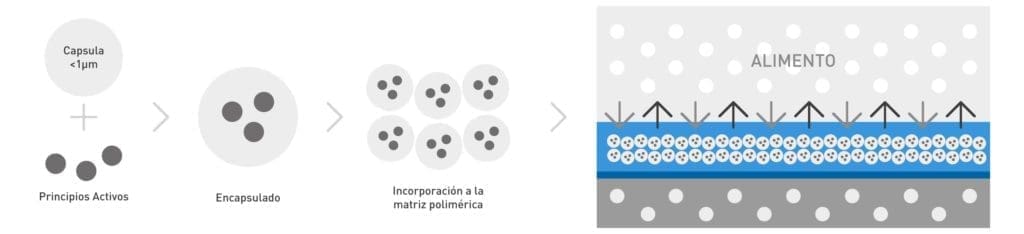

Our technology, developed and patented by NUREL, called Active Packaging, involves incorporating encapsulated active ingredients into the polymer matrix to provide antioxidant and antimicrobial properties to the film.

Active packaging to extend food life

Firstly, an appropriate active ingredient is selected for each formulation, with ingredients sourced from natural origins widely used in the food industry.

The active ingredients are released from the capsules through a controlled diffusion method (pressure difference inside and outside the capsule). At the same time, gas-phase radicals permeate through the capsule-containing layer and are stabilized by the active ingredients.

Our active packaging technology can also be applied to other polymers besides polyamide.

Natural origin active ingredients incorporated

Antioxidant and antimicrobial active ingredients are based on natural essential oils. These active ingredients are incorporated within the polymer and are activated in the vapor phase. Direct contact between the food and the active ingredients is not necessary for their effectiveness, making it an ideal solution for food trays packaged in a protective modified atmosphere (MAP).

Natural origin active ingredients incorporated

Antioxidant and antimicrobial active ingredients are based on natural essential oils. These active ingredients are incorporated within the polymer and are activated in the vapor phase. Direct contact between the food and the active ingredients is not necessary for their effectiveness, making it an ideal solution for food trays packaged in a protective modified atmosphere (MAP).

Applications

Deep thermoforming

NUREL offers a wide selection of polyamides and copolyamides designed for deep thermoforming packaging, with a focus on providing superior barrier properties and puncture resistance to effectively extend the shelf life of food products, thus contributing to the reduction of food waste. This type of packaging is particularly suitable for the preservation of large portions of fresh meat and whole cheeses.

Meat and bone-in meat packaging

Packaging for sharp-edged foods requires high puncture resistance, flexibility, moisture barrier, transparency, and an attractive gloss. NUREL offers a range of special copolyamides and polymers with high oxygen barrier properties for the manufacturing of vacuum bags and thermoformed packaging for meat.

Skin Packaging

Skin packaging is gaining popularity due to its lightweight and visually appealing design, as well as its superior technical performance. NUREL provides specially formulated copolyamides that exhibit exceptional strength, sealing capabilities, barrier properties, and unmatched glossiness.

Related markets

Packaging

Polyamides are used in the packaging industry for their good mechanical properties, barrier properties and for providing a quality finish due to their high gloss and transparency.

OTHERS SOLUTIONS

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter