PA, PBT, PET and PBT/PET compounds for day-to-day activities

Engineering plastics are used in a wide range of applications that reach the end consumer. Household appliances, tools, electronic devices, sports equipment and kitchen appliances all feature materials made of NUREL polyamide and PBT compounds in their components.

These applications require specific solutions for each component, from high thermal and mechanical resistance, abrasion resistance, hydrolysis resistance, or are even used to replace metals due to their excellent properties and the resulting cost reduction.

In addition, thanks to our experience in compounding and our commitment to sustainability, we offer a wide range of recycled PA6 & 66 compounds, which improve the environmental impact of all types of products.

Solutions

Surface Finish

Our range of reinforced PA6 grades, is designed to deliver a superior surface finish while maintaining high mechanical performance. It is ideal for visible or aesthetic components. Additionally, our PP compounds include talc-reinforced grades and scratch-resistant options, suitable for technical applications where appearance also matters.

Flame Retardant

High Thermal stabilization

We offer PA6 and PA66 grades with advanced thermal stabilization up to 180 °C, also available in metal- and halogen-free formulations.

Applications

SKI BINDINGS

Reinforced compounds of Promyde® PA6 are used in the manufacturing of ski bindings due to their lightweight nature, impact resistance, dimensional stability, and flexibility. They also exhibit resistance to moisture and extreme temperatures, enhancing the performance and durability of sports equipment. Additionally, with our Recomyde® line, these parts can be produced using recycled materials, contributing to sustainability.

Tools

Promyde's extensive range of materials are a commitment to technical and value solutions with excellent mechanical properties and finishes for the manufacture of power tool parts and housings. Reinforced (glass fiber) and impact-modified grades provide excellent compatibility in bi-material injection molding processes where they are combined with other materials, such as 2K elastomers.

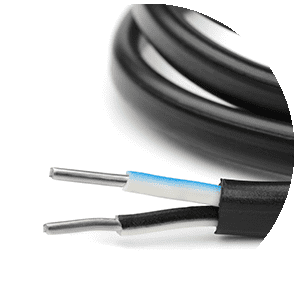

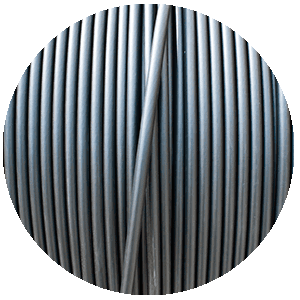

MONOFILAMENTS FOR LAWN MOWERS AND TRIMMERS

Promyde® PA6 grades for extrusion are used in the manufacturing of monofilaments for lawnmowers and trimmers due to their flexibility, abrasion resistance, and ability to withstand adverse weather conditions such as ultraviolet (UV) radiation, temperature variations, and humidity.

Kitchen utensils

Kitchen utensils made from reinforced PA and PBT are an alternative to metal due to their characteristics of strength, durability, and lightweight. These polymers are reinforced with materials such as fiber and glass beads to enhance their mechanical properties and scratch resistance.

HOME APPLIANCES

NUREL offers a wide range of products, including PP, PA, and PBT specifically designed for use in structural parts and components of home appliances. Our materials are tailor-made to meet the rigorous performance and durability requirements essential for the operation of these devices.

ELECTRIC TOOLS

Reinforced grades of Promyde PA6 are used in the manufacturing of casings for professional-grade electric tools. These tools need to be lightweight while maintaining high impact resistance, temperature resistance, and dimensional stability, as they are used in both indoor and outdoor environments where efficiency is crucial.

RELATED MARKETS

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter