Polyamide 6 for Weight Reduction

Weight reduction is a crucial factor in product design, especially in markets such as aviation and automotive, where the primary goals are to reduce fuel consumption, lower CO₂ emissions, and enhance dynamic performance.

To address this challenge, our Promyde® PA6 range provides two key strategies for effective weight reduction:

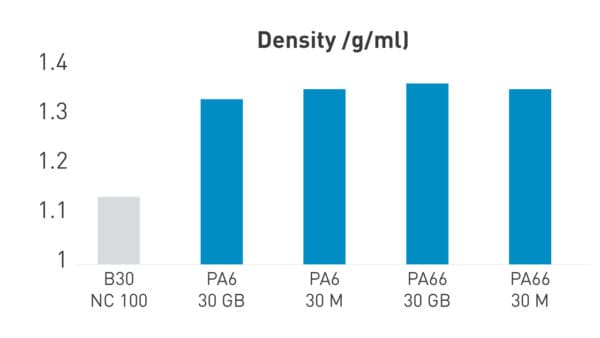

- Development of lighter polymers: The objective is to engineer high-performance polymers that maintain comparable properties to conventional materials, while offering lower density to contribute to overall weight reduction.

- Substitution of higher density materials with technical engineering polymers: This approach involves replacing heavier materials, such as metals, with advanced technical polymers that meet the required mechanical and thermal properties, enabling significant weight savings without compromising performance.

Lightweight pa6 for weight reduction

PA6 Nano Clay (NC)

Reinforced grades with Promyde® Nano Clay feature clay nanoparticles embedded within the polymer matrix, resulting in enhanced mechanical properties while contributing to weight reduction.

PA6 Weight Reduction (WR)

Our Promyde® WR grades offer a lightweight alternative that enables significant weight reduction while maintaining the same performance characteristics as conventional materials.

PA6 reinforced with Hollow Beads (HB)

Promyde® HB grades incorporate hollow glass beads as reinforcement, delivering an additional weight reduction of up to 20% without compromising material performance

PA6 for Replacing Heavy Materials in Various Applications

Substitution strategies include:

Replacing metals with electrically, thermally, or electro-thermally conductive polymers, offering functional performance with reduced weight.

Using high-modulus, high-temperature resistant solutions as alternatives to metal components in demanding environments.

Replacing solid parts with hollow structures, manufactured using water or gas-assisted injection molding, further reducing material usage and weight.

In summary, Promyde® offers a versatile range of solutions for weight reduction in injection-molded parts, delivering measurable benefits in terms of energy efficiency, sustainability, and overall performance.

Applications

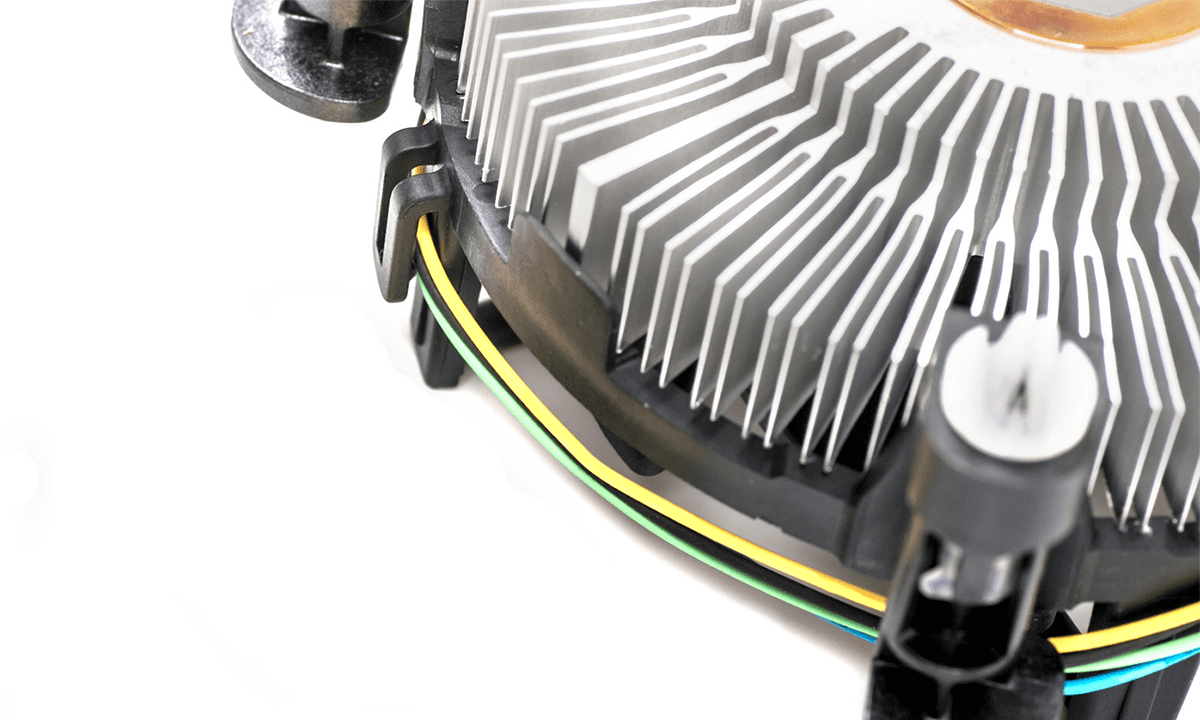

HEAT SINKS

NUREL offers a Promyde® PA thermally conductive range, ideal for replacing aluminum in heat sinks for LED lights. This new PA6 compound ensures efficient heat transfer from electronic components, maintaining optimal operating temperatures.

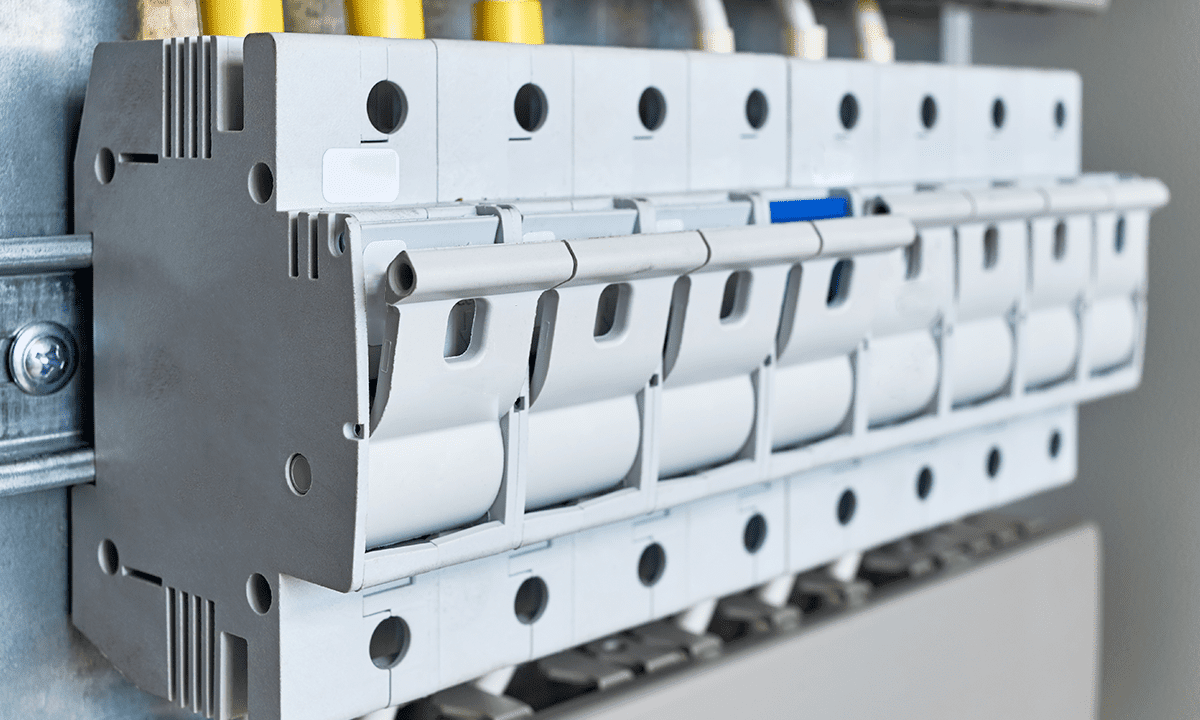

Electrical components

Electrical components must meet high requirements including high temperature resistance, dimensional stability and chemical resistance. This type of parts uses PA, PBT, PP and PP compounds. These materials ensure optimum and safe performance in electrical applications.

Electric vehicle

NUREL has developed engineered polymers for electric vehicles, improving autonomy, safety and sustainability. Our range of compounds, including PA6, PA66, PBT, PET, PP and PA, recycled PET and PP, offers solutions for interior, exterior, aesthetic finishes and metal replacement components, helping to reduce vehicle weight and ensuring high performance.

RELATED MARKETS

MOBILITY AND AUTOMOTIVE

The mobility sector has always been a leader in mechanical innovation and process optimization. At NUREL, we support this evolution with our range of engineering polymers - PA6, PA66, PBT, PET and PP - designed to respond to the industry's demand for lighter, more sustainable and efficient solutions.

Electrical and electronic

NUREL PA, PBT, PET, PBT/PET and PP compounds are present in parts and components of electrical and household appliances. Parts molded with Promyde®, Proxylene®, Olexene®, or Recomyde® can be found in food processors, white goods such as refrigerators, washing machines and dryers.

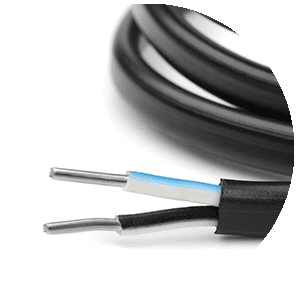

Cables and Pipes

Promyde® PA and Proxylene® PBT polymers for UL 83-certified cables such as copper building wire, PVC Nylon tray cable, THHN cable and THWN cable, fiber optic cable, as well as tubes and pipes for cable management systems.

INDUSTRIAL

The industrial sector demands high-performance materials to meet stringent standards of efficiency, durability and strength. Our range of engineering polymers and recycled technical composites offer high-value solutions for the manufacture of industrial machinery and precision components.

OTHERS SOLUTIONS

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter