OLEXENE: POLYPROPYLENE PERFORMING COMPOUNDS

NUREL, as a highly experienced and innovative leader in engineering polymer production, is renowned for its commitment to research and development. Building on our extensive expertise in compounds of PA6, PA66, PBT and PET, we have recently made substantial investments in expanding our extrusion facilities.

These investments enable NUREL to offer a new comprehensive range of Prolypropylene compounds under the Olexene® brand. This selection covers both reinforced and unreinforced grades with various viscosities to meet diverse application needs.

OLEXENE® PP MAIN PROPERTIES

The combination of versatility, durability, lightweight, cost-effectiveness, ease of processing, and recyclability makes Olexene® the material of choice for a wide range of applications.

- VERSATILITY: Olexene PP range offers various products to achieve the necessary properties, including enhanced stiffness or impact resistance, rendering it suitable for a broad spectrum of applications.

- LIGHTWEIGHT: The Olexene PP compounds range features low density references, making them ideal for applications where weight reduction is crucial, such as in the automotive industry.

- DURABILITY: Olexene PP compounds exhibit remarkable resistance to cracking, breaking, and chemical damage, establishing them as a durable material well-suited for demanding applications.

- RECYCLABILITY: Olexene compounds are highly recyclable, making them an environmentally-friendly choice for applications that prioritize sustainability.

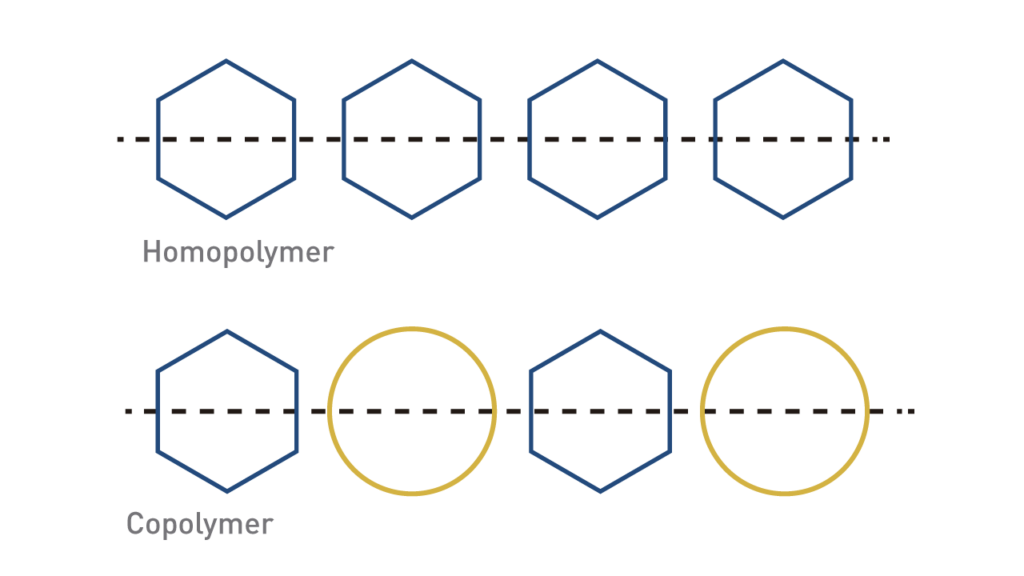

RANGE OF OLEXENE® PP COPOLYMERS AND HOMOPOLYMERS

Olexene offers Polypropylene (PP) compounds based on two different types of PP, depending on their molecular structure: PP homopolymer and PP copolymer.

- OLEXENE PP HOMOPOLYMER is a polymer consisting of a single monomer. It exhibits a linear structure with high crystallinity, resulting in stiffness, strength, and heat resistance. Olexene PP homopolymer is suitable for applications demanding high stiffness, such as automotive parts and household appliances.

- OLEXENE PP COPOLYMER is a polymer formed through the combination of two or more monomers. PP copolymers possess a randomized molecular structure, leading to lower crystallinity, increased flexibility, and enhanced impact resistance. . PP copolymers are typically employed in applications requiring greater flexibility, like injection-molded products.

Olexene PP homopolymer and Olexene PP copolymer exhibit variations in their molecular structure, crystallinity, and mechanical characteristics, rendering them appropriate for diverse applications.

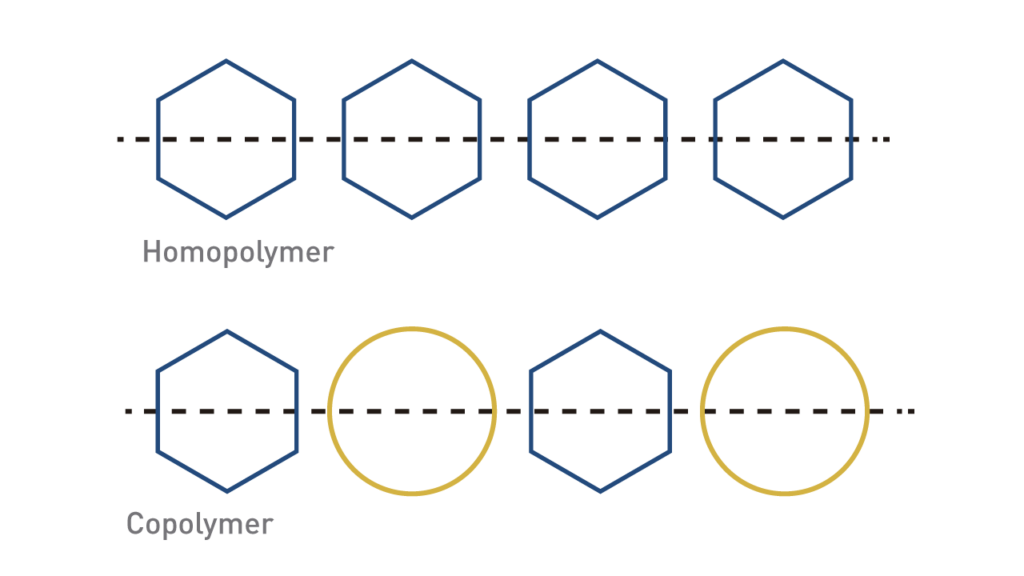

RANGE OF OLEXENE® PP COPOLYMERS AND HOMOPOLYMERS

Olexene offers Polypropylene (PP) compounds based on two different types of PP, depending on their molecular structure: PP homopolymer and PP copolymer.

- OLEXENE PP HOMOPOLYMER is a polymer consisting of a single monomer. It exhibits a linear structure with high crystallinity, resulting in stiffness, strength, and heat resistance. Olexene PP homopolymer is suitable for applications demanding high stiffness, such as automotive parts and household appliances.

- OLEXENE PP COPOLYMER is a polymer formed through the combination of two or more monomers. PP copolymers possess a randomized molecular structure, leading to lower crystallinity, increased flexibility, and enhanced impact resistance. . PP copolymers are typically employed in applications requiring greater flexibility, like injection-molded products.

Olexene PP homopolymer and Olexene PP copolymer exhibit variations in their molecular structure, crystallinity, and mechanical characteristics, rendering them appropriate for diverse applications.

OLEXENE POST-CONSUMER (PCR) RECYCLED PP

In line with NUREL’s dedication to sustainability across its production stages, OLEXENE offers 100% recycled polypropylene solutions.

This Polypropylene post-consumer polymer is retrieved from post-consumer waste streams. Recycling post-consumer PP waste into new products plays a crucial role in plastic waste in landfills and the environment, preserving the natural resources and the reducing energy consumption and emissions emissions associated with the production of new plastic products.

Download our catalogues

Olexene

OLEXENE PP POLYMER SOLUTIONS

Glass Fibers

Glass fiber reinforcement significantly enhances stiffness, strength, and dimensional stability, resulting in improved structural integrity and performance.

Mineral Fillers

Mineral fillers like talc and calcium carbonate are commonly combined with PP. These fillers serve to enhance the mechanical properties of PP and minimize shrinkage during the cooling process. Mineral-filled PP finds frequent application in automotive parts, packaging, and household appliances. These fillers can improve the mechanical properties of PP and reduce its shrinkage during the cooling process.

Impact Modifiers

Impact modifiers are employed to enhance the toughness and impact resistance of PP. They effectively enhance PP performance in low-temperature conditions, mitigating the risk of cracking or breaking.

Flame Retardant

Flame retardant additives are used to improve the flammability resistance of PP. They reduce the risk of fire and slow down the spread of flames.

Stabilizers

Stabilizers are employed to enhance PP’s resistance against degradation caused by heat, light, and oxidation. Typical stabilizers for PP encompass antioxidants, ultraviolet (UV) stabilizers, and thermal stabilizers.

Colors

We offer a wide range of customizable color options available upon request, providing tailored solutions for our clients.

Recycled PP

OLEXENE offers some grades made with 100% recycled polypropylene. This Polypropylene recycled polymer is retrieved from post-consumer waste streams.

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter