POLYAMIDE 6 AND COPOLYAMIDES FOR THE PRODUCTION OF TRIPLE BUBBLE FILM

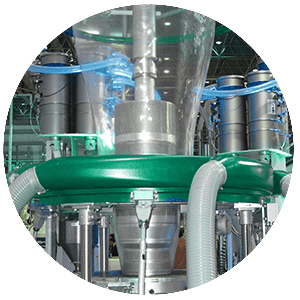

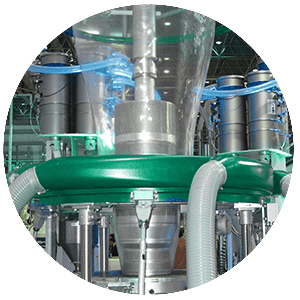

The main objective of using triple bubble technology for film manufacturing is to obtain an optimal controlled shrinkage and to improve the mechanical properties of films with reduced thickness. The use of polyamide is mainly recommended for sausage casing and in coextrusion for high barrier packaging with heat shrink properties.

Promyde® offers a wide range of polyamide 6 polymers specially designed for triple bubble film extrusion. Our products are adapted to all triple bubble film processing technologies.

Promyde PA6 has a high barrier to oxygen and other gases, aromas and flavors, transfer heat shrink properties and compatibility with other materials used in coextrusion.

Our range of PA6 Promyde for triple bubble extrusion offers extremely stable high quality and excellent processing with the lowest moisture and free monomer contents in the market.

PROMYDE FOR TRIPLE BUBBLE EXTRUSION

- Promyde offers PA6 of viscosity 3.8 with or without lubrication.

- Low moisture content & monomer

- Improved gas barrier (O2, CO2,…) aromas and chemicals

SPECIFIC PROPERTIES FOR TRIPLE BUBBLE EXTRUSION

- Availability of degraded products with increased CO2 permeability

- Special grades with heat shrink properties

- Special grades with sealing properties

- High temperature HT resistance, available for sterilization treatments

SPECIFIC PROPERTIES FOR TRIPLE BUBBLE EXTRUSION

- Availability of degraded products with increased CO2 permeability

- Special grades with heat shrink properties

- Special grades with sealing properties

- High temperature HT resistance, available for sterilization treatments

Download our catalogues

Promyde - Film

Solutions

Barrier solutions

We offer innovative solutions in PA, copolyamides, and barrier materials for food packaging, developed to enhance oxygen barrier properties and extend shelf life.

Sealing films

Polyamides and copolyamides specially developed for films, lids, thermoformed trays, and vacuum bags. We offer low-sealing-temperature copolyamides for optimized packaging performance.

Low curling films

MARKETS

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter