PA compounds for cable extrusion

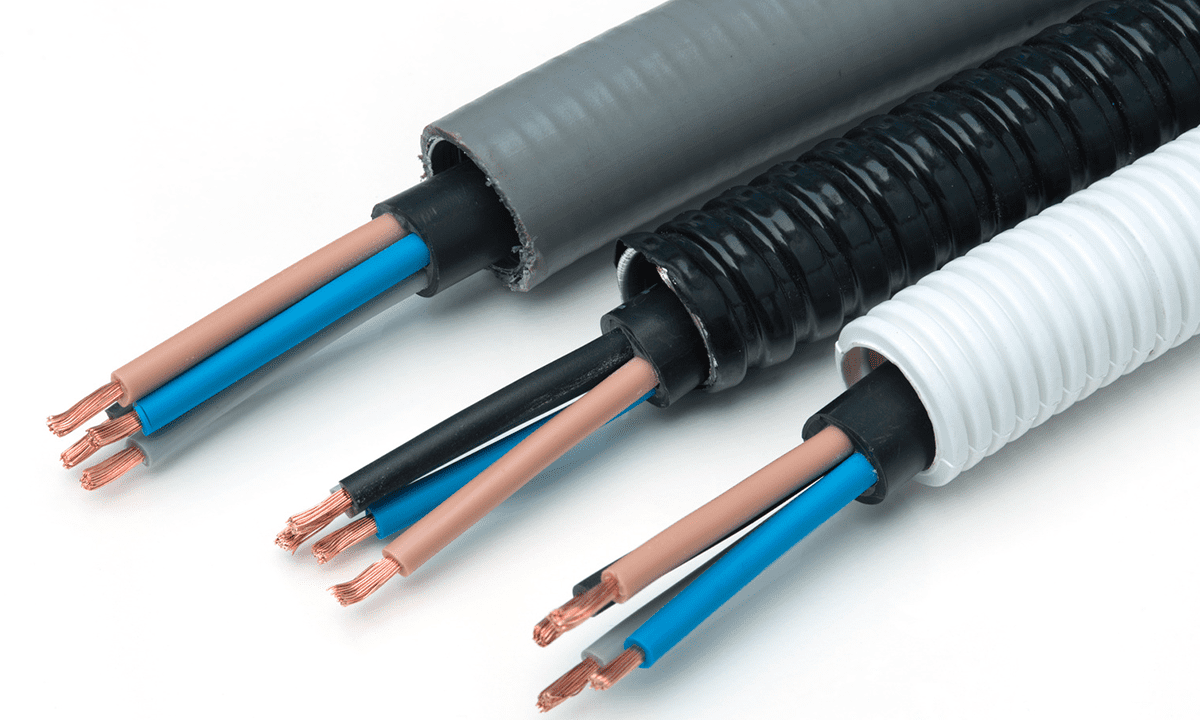

Promyde® and Proxylene present a range of PA6 and PBT polymers specifically for the extrusion of both internal and external cable sheathing; achieving optimum protection for all cables manufactured with our polymers.

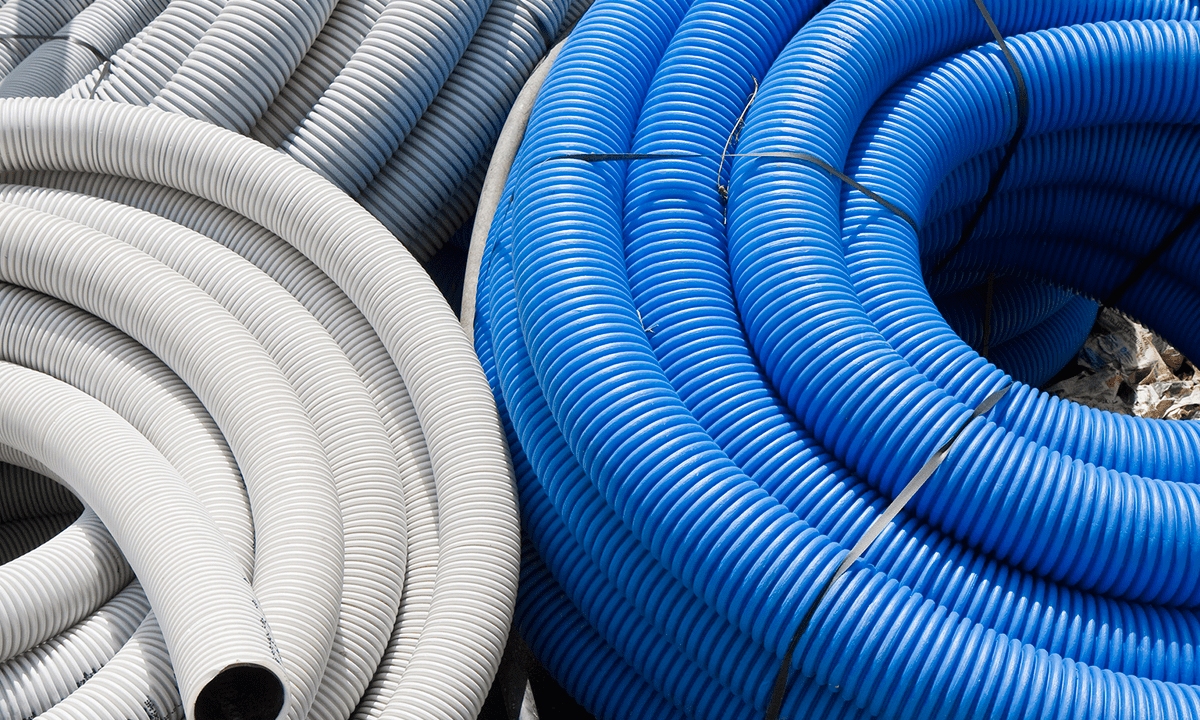

Another important application of Promyde PA6 is the production of flexible and corrugated pipes for electrical conduits used to protect cables in automobiles, trucks, trains and industrial machinery.

Air pipes and air conditioning systems have requirements for mechanical strength at low temperatures, UV and heat resistance in extreme temperature environments over time and with requirements for flexible properties, they need very sophisticated extrusion compounds.

MEETING THE MOST STRINGENT REQUIREMENTS

- Compliance with stringent European rail standards EN 45545-2

- Resistance to breakage at extreme temperatures

- Thermal stability for optimum performance on the move and under temperature

- Suitable for indoor and outdoor use

POLYAMIDE FOR CABLE EXTRUSION

Our high viscosity Promyde range, with its exceptional impact resistance, strength, high toughness at extreme temperatures, low abrasion, high process performance, good electrical insulation and chemical resistance properties, is the ideal material to achieve high durability of polyamide cable sheathing.

The most common cable applications include nautical cables, fiber optic cables as well as THHN, THWN and TFFN cables.

Cable extrusion benefits

Promyde PA6 provides consistent wire thickness in the most critical processes such as micro and millimeter extrusions. Promyde can be modified to suit indoor and outdoor applications with different performance requirements in extreme temperature environments, stationary and moving mechanical environments.

CORRUGATED PIPE SYSTEMS

Small and large diameter pipes are often produced by corrugated extrusion. Thanks to the use of our range of products Promyde drive systems benefit from added flexibility and optimal protection.

PROMYDE FOR ELECTRICAL CONDUITS

Promyde can be used in extrusion processes for the production of electrical conduits that combine properties of flexibility, mechanical performance and heat resistance so that vehicle electrical systems can operate in varying climatic conditions without technical problems.

HIGH VISCOSITY PBT GRADES

Proxylene B97 P2 is a high viscosity PBT grade with good processability for the extrusion of optical fiber tubes, cables, pipes and profiles.

Proxylene B97 P2 is used in a wide range of applications where a combination of mechanical properties, thermal resistance and dimensional stability are needed.

HIGH VISCOSITY PBT GRADES

Proxylene B97 P2 is a high viscosity PBT grade with good processability for the extrusion of optical fiber tubes, cables, pipes and profiles.

Proxylene B97 P2 is used in a wide range of applications where a combination of mechanical properties, thermal resistance and dimensional stability are needed.

Solutions

High Thermal stabilization

We offer PA6 and PA66 grades with advanced thermal stabilization up to 180 °C, also available in metal- and halogen-free formulations.

UV Resistance

To increase the lifetime of parts exposed to sunlight, we offer compounds with UV resistant properties.

Flame Retardant

Flame resistant grades that meet the most demanding requirements, from V2 to V0 in UL94 and a GWFI of up to 960º. Halogen-free solutions and EN45545 grades available.

Electrical conductivity

We offer PA6 compounds with a wide range of electrical conductivities, from anti-static grades to materials with high conductivity grades (from 10 to 1012 Ohm).

Thermal conductivity

Promyde® introduces a new range of thermally conductive PA6, developed for applications requiring efficient heat dissipation. Ideal for components where thermal management is essential.

Applications

Optical fiber cable

Optical fiber cables are crucial in modern telecommunications. NUREL has developed a specific range of Proxylene (PBT) to reinforce and protect the delicate optical fibers within the cable. We also offer special grades of Promyde PA6 for optical fiber cables with high impact resistance requirements.

Cable jacketing

At NUREL, we provide heat-resistant, UV-stable and even flame-retardant polyamide and PBT compounds for the production of cables, wires and cable protection.

Corrugated pipes

Promyde B33 is commonly used for corrugated pipes of this diameter, and Promyde B36 and B38 for larger diameters.

Pipes and Tubes

Promyde® PA6 is widely used in pipe extrusion due to its exceptional strength, durability, and ability to withstand extreme temperatures, corrosion, pressure, and chemical resistance. Additionally, the Promyde PA range offers flexible grades specifically for this type of application.

RELATED MARKETS

PROCESSES

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter