OPTICAL CABLES WITH PBT AND PA CORE

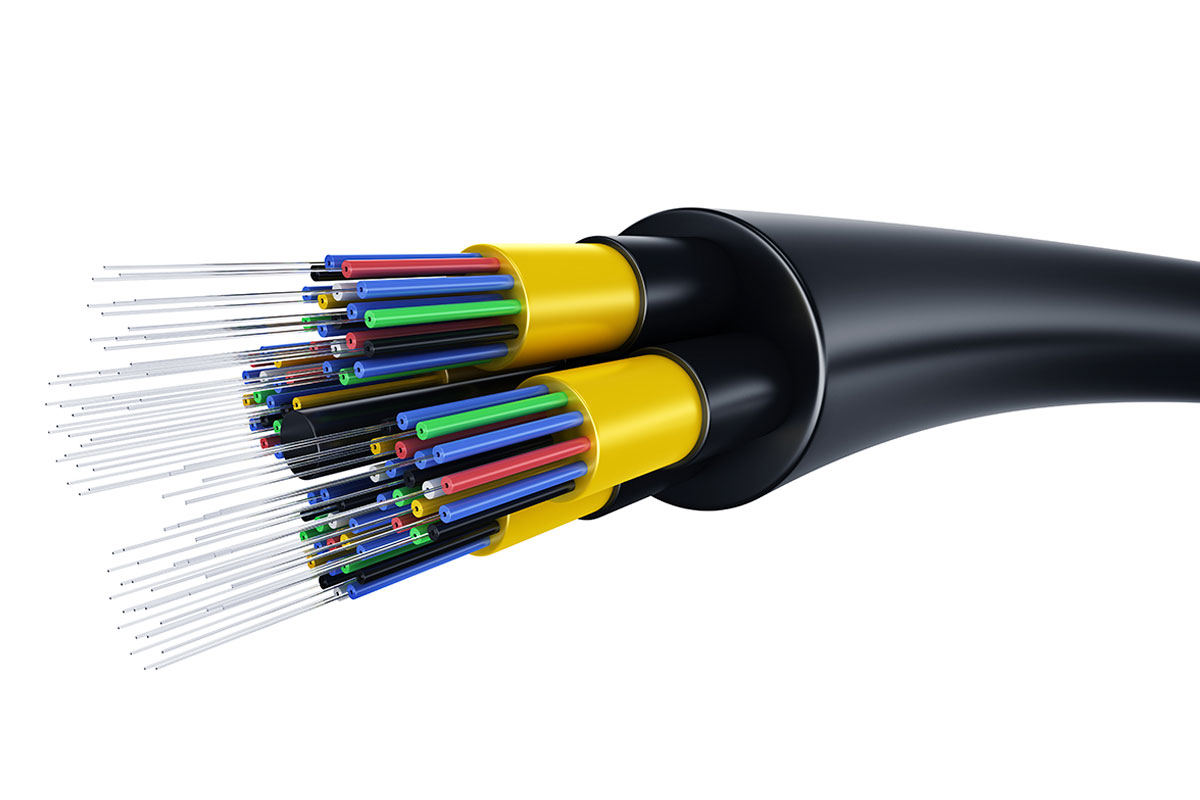

Optical cables, also known as fiber optic cables, are crucial on modern telecommunications. At the core of these cables lies Polybutylene Terephthalate (PBT) and occasionally PA. These materials are strategically employed to fortify and shield the delicate optical fibers within the cable.

PBT’s properties of strength, resilience, temperature stability, and chemical resistance makes it an indispensable component in optical cable production. As the market demand for high-speed, reliable data transmission continues to grow, PBT and PA e remain as key enablers in this industry.

The Role of Proxylene PBT on optical fiber cable production

- Cable Strength and Durability: PBT is renowned for its exceptional mechanical properties, including high tensile strength and durability. This fact provides robust protection to the fragile optical fibers within the cable and ensure the integrity of the transmission.

- Temperature Stability: Optical cables often traverse various environmental conditions, from extreme heat to freezing cold. PBT maintain its structural stability across temperatures, ensuring reliable cable performance.

- Chemical Resistance: Exposure to moisture, chemicals, and other environmental factors can compromise cable performance PBT resistance to these elements safeguards the optical fibers, ensuring long-term functionality.

Polyamide's Role for Specific Requirements on fiber optic cable

For applications demanding increased impact resistance, Polyamide 6 (PA 6) emerges as the optimal choice. Its unique properties cater to very specific requirements of optical cable production.

Optical fibre cable applications:

- Telecommunications and data centers: Optical cables reinforced with PBT and PA present on our modern communication networks, enabling high-speed data transmission.

- Industrial Settings: In industrial applications, these cables support automation, control systems, and high-speed data transfer for machinery.

Polyamide's Role for Specific Requirements on fiber optic cable

For applications demanding increased impact resistance, Polyamide 6 (PA 6) emerges as the optimal choice. Its unique properties cater to very specific requirements of optical cable production.

Optical fibre cable applications:

- Telecommunications and data centers: Optical cables reinforced with PBT and PA present on our modern communication networks, enabling high-speed data transmission.

- Industrial Settings: In industrial applications, these cables support automation, control systems, and high-speed data transfer for machinery.

MARKETS

SOLUTIONS

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter