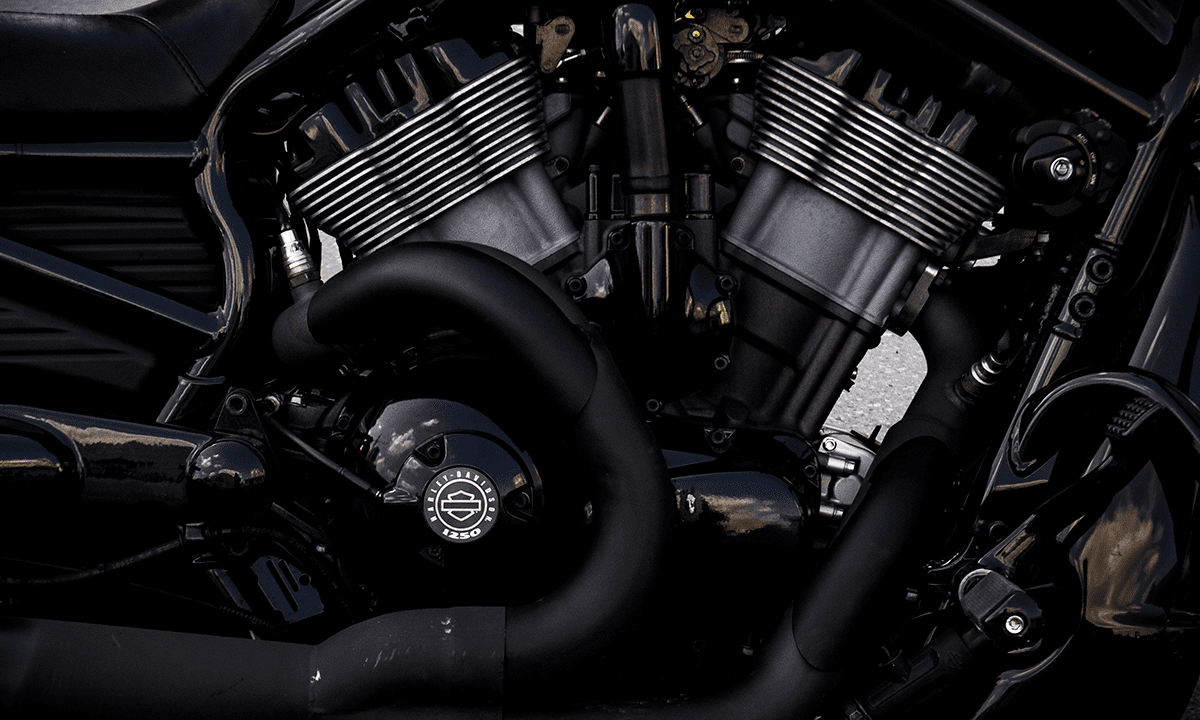

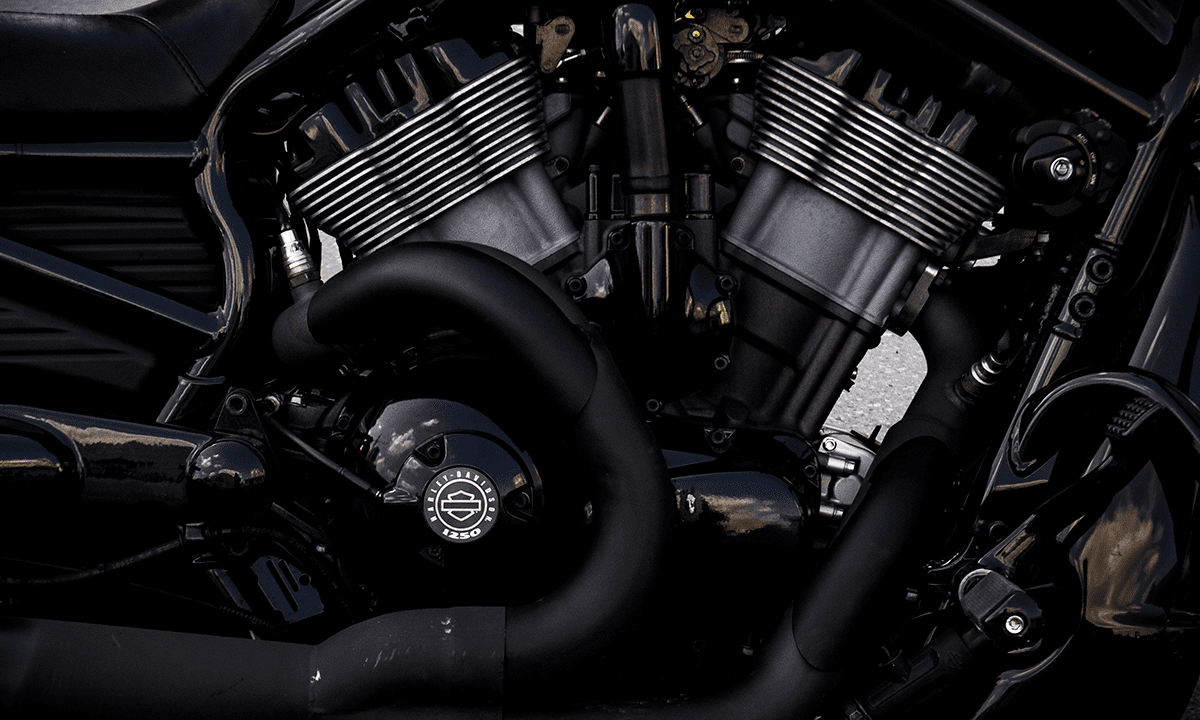

PA and PBT compounds for automotive under-the-hood-applications

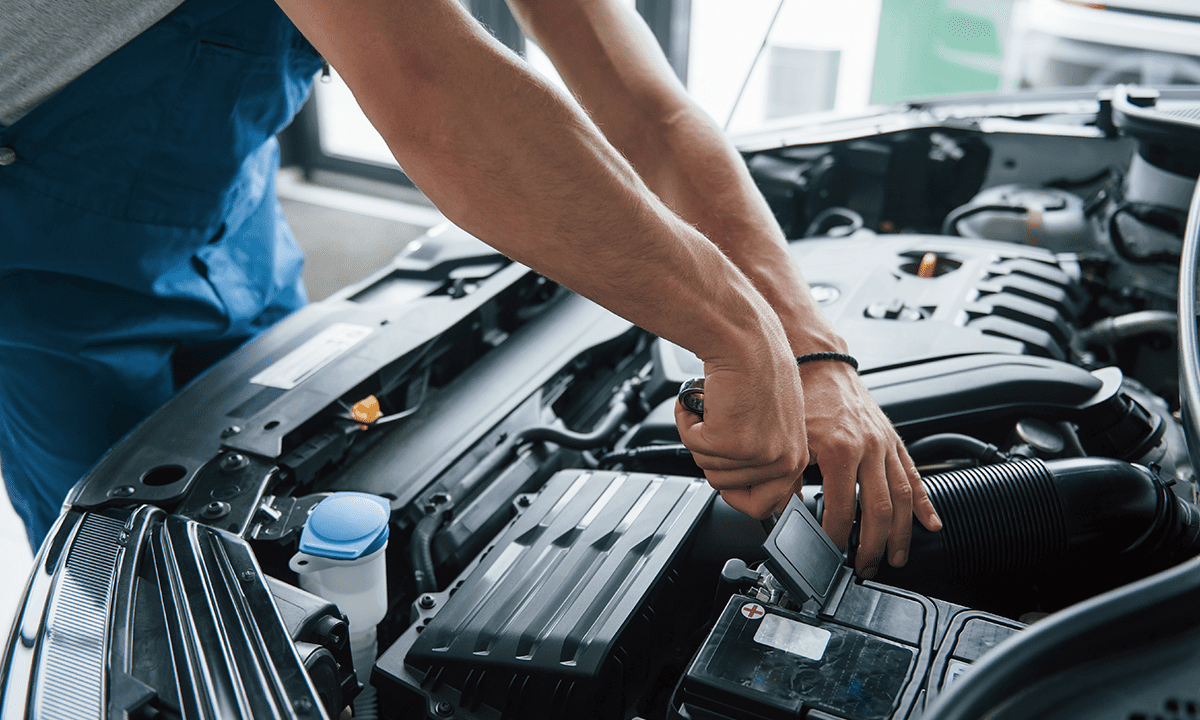

The automotive industry is constantly evolving, incorporating new materials to meet the demanding requirements of under-the-hood applications. In this regard, plastic materials have proven to be a versatile and effective choice.

Specifically, PA (polyamide) and PBT (polybutylene terephthalate) compounds have demonstrated their capabilities in these applications, tackling challenges such as temperature resistance, dimensional stability, exposure to chemicals and hydrocarbons, galvanic corrosion, and hydrolysis.

PA applications fro automotive components with high requirements

Promyde’ s PA6 compounds offer a unique combination of properties, including mechanical, thermal, chemical and moisture resistance. This makes them versatile materials for a wide range of under-hood applications. NUREL offers reinforced grades with fiberglass and other additives to further enhance their mechanical and thermal characteristics, adapting to the specific requirements of each application.

Promyde PA6 applications in automotive parts include engine covers, air ducts, electrical connectors, intake manifolds, rocker covers, and cooling systems.

NUREL offers a wide range of reinforced and unreinforced PA grades with different viscosities and additive packages to meet the most demanding requirements. Moreover, their new PA6 compounds with thermal stabilization can replace, in many cases, PA66 grades, even regarding hydrolysis resistance.

HSA grades in PA for automotive applications

On the other hand, Promyde’s HSA grades exhibit long-term thermal stability, ensuring mechanical properties are maintained even at high temperatures under the car’s hood. These grades have surpassed tests and evaluations of 3000 hours at 180°C, ensuring optimal performance under these extreme conditions. Additionally, Nurel has developed a new range of PA6 with fiberglass that is resistant to hydrolysis and antifreeze, complying with rigorous automotive industry standards.

HSA grades in PA for automotive applications

On the other hand, Promyde’s Promyde HSA have long-term thermal stability, always maintaining the required mechanical properties even at high temperatures under the hood of the car. These grades have surpassed tests and evaluations of 3000 hours at 180°C, ensuring optimal performance under these extreme conditions. In addition, Nurel has developed a new range of PA6 with hydrolysis and antifreeze resistant fiberglass, meeting stringent automotive industry standards.meeting the rigorous standards of the automotive industry.

PBT compounds for the car engine

Proxylene PBT grades stand out for their dimensional stability, heat resistance, low moisture absorption, and resistance to chemicals and solvents. These properties make them a popular choice for under-the-hood applications, where parts must withstand demanding conditions and maintain performance over time.

Some common applications of Proxylene’s PBT compounds in the engine compartment include electrical connectors, housings, and supports for various automotive components, thanks to their mechanical strength and ability to maintain their shape under load. Additionally, Proxylene offers a combination of thermal resistance and durability, making it a suitable material for manufacturing air ducts in the engine compartment. It also provides excellent chemical and moisture resistance, making it ideal for applications in contact with refrigerant fluids and components in the fuel injection system.

MARKETS

Automotive

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter