SAME PERFORMANCE WITH IMPROVED LASER TRANSPARENCY

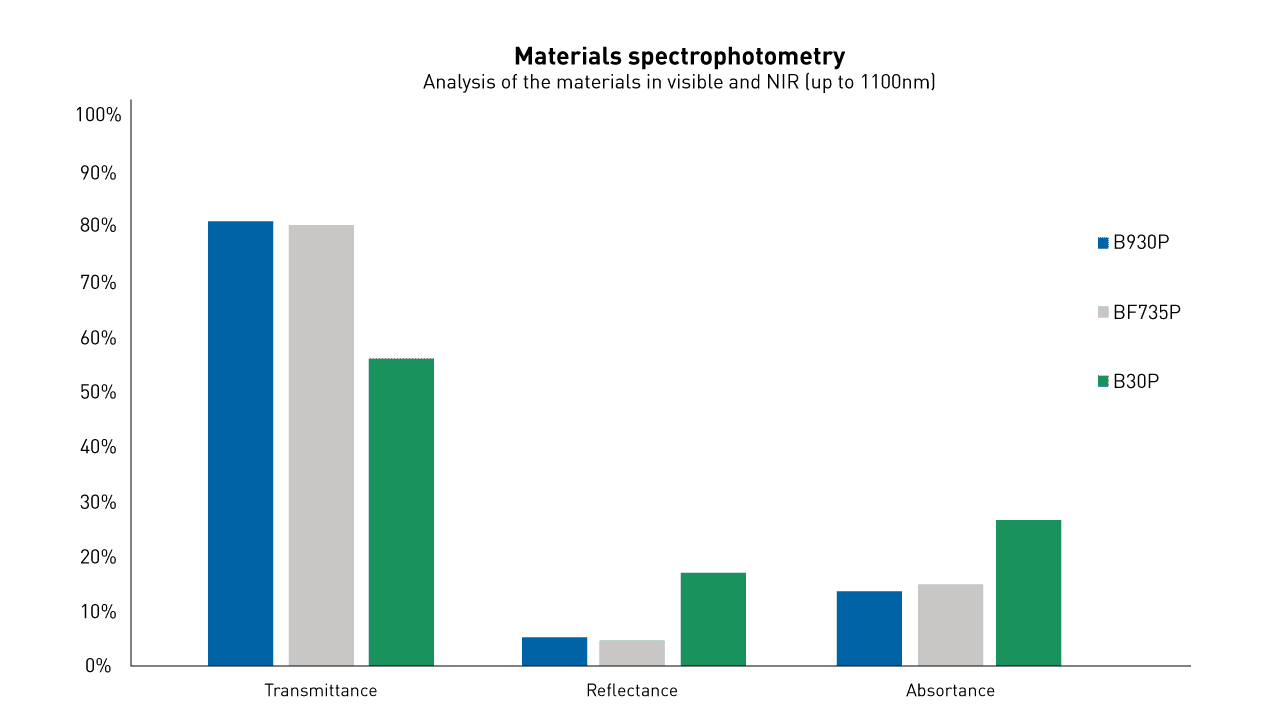

PROMYDE’s new polyamides have been developed based on a change in morphology, allowing a four-fold improvement in direct laser transmission and improving overall transmission by up to 50%.

This new solution is a milestone, as laser transparency for polyamide 6 has not been achieved before, and mechanical properties are comparable to those of standard unreinforced PA6.

Laser welding consists of joining a transparent part by means of laser beams, melting the underlying half of the component that absorbs the laser beams. Thus, laser welding is the fusion of a laser-transparent material with a laser-absorbing material.

With the improved laser transparency offered by Promyde, it is now possible to weld thicker thicknesses with an unbeatable surface finish and weld strength. In this way, applications that previously required other joining methods can now be laser welded.

Therefore, new Promyde laser welding polyamide not only opens up completely new possibilities, but also makes a significant contribution to the efficiency of the part welding process.

LASER WELDING: CRYSTALLINITY AND MORPHOLOGY AS KEY FACTORS

Laser welding of partially crystalline thermoplastics is more complex than that of amorphous plastics due to the scattering of the laser beam in the spherulites. This problem was recurrent in all partially crystalline plastics, especially with polyamide 6.

Thanks to the Promyde laser welding innovation, it is now possible to create a Polyamide 6 structure with improved optical and mechanical properties.

DIRECT TRANSMITTANCE: TRUE LASER TRANSPARENCY

In addition to increasing laser transparency, Promyde laser welding polyamides improve the quality of the transmitted laser beam, i.e. direct transmittance.

In the case of Promyde laser welded polyamides, the direct transmission reaches 96% of the total transmission. This is directly related to reduced laser beam broadening and therefore to exceptional weld quality.

DIRECT TRANSMITTANCE: THE TRUE LASER TRANsPARENCY

In addition to increasing laser transparency, Promyde laser welding polyamides improve the quality of the transmitted laser beam, i.e. direct transmittance.

In the case of Promyde laser welded polyamides, the direct transmission reaches 96% of the total transmission. This is directly related to reduced laser beam broadening and therefore to exceptional weld quality.

LASER WELDING: CRYSTALLINITY AND MORPHOLOGY AS KEY FACTORS

Advantages of laser welding are important for small parts where flexible geometric design and clean operations are needed. Thus, Promyde grades for laser welding:

- They allow materials to be joined with high precision without damage and without structural changes. Laser welding avoids the need for adhesives and/or other bonding materials.

- It is especially interesting for electronic devices, automotive control units or assemblies with sensors.

Download our catalogues

Promyde - Injection

Applications

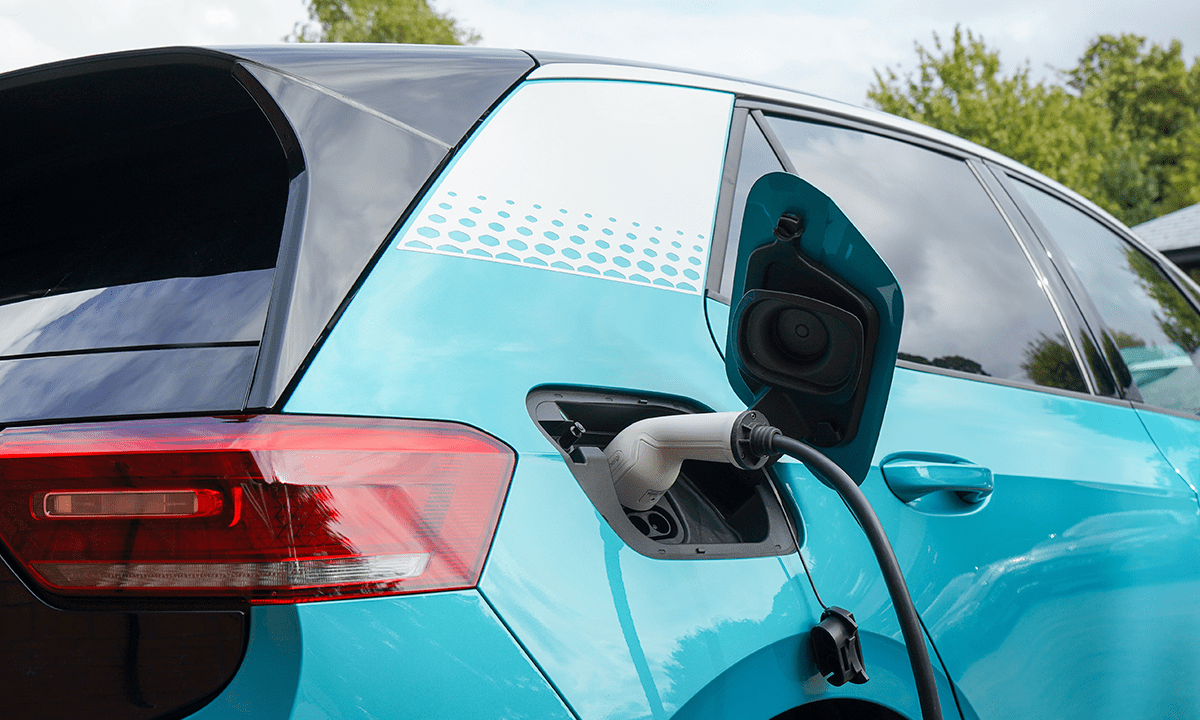

Electric vehicle

NUREL has developed engineered polymers for electric vehicles, improving autonomy, safety and sustainability. Our range of compounds, including PA6, PA66, PBT, PET, PP and PA, recycled PET and PP, offers solutions for interior, exterior, aesthetic finishes and metal replacement components, helping to reduce vehicle weight and ensuring high performance.

HOME APPLIANCES

NUREL offers a wide range of products, including PP, PA, and PBT specifically designed for use in structural parts and components of home appliances. Our materials are tailor-made to meet the rigorous performance and durability requirements essential for the operation of these devices.

Reinforced Structural Parts

Vehicle structures, such as handgrips, require technical solutions with high fluidity and a good surface finish, which also allow efficient heat dissipation to ensure optimum function and resistance under demanding conditions.

Electrical components

Electrical components must meet high requirements including high temperature resistance, dimensional stability and chemical resistance. This type of parts uses PA, PBT, PP and PP compounds. These materials ensure optimum and safe performance in electrical applications.

RELATED MARKETS

INDUSTRIAL

The industrial sector demands high-performance materials to meet stringent standards of efficiency, durability and strength. Our range of engineering polymers and recycled technical composites offer high-value solutions for the manufacture of industrial machinery and precision components.

MOBILITY AND AUTOMOTIVE

The mobility sector has always been a leader in mechanical innovation and process optimization. At NUREL, we support this evolution with our range of engineering polymers - PA6, PA66, PBT, PET and PP - designed to respond to the industry's demand for lighter, more sustainable and efficient solutions.

Consumer goods

Engineering plastics are used in a multitude of applications that reach the end consumer. Household appliances, tools, electronic devices, sports equipment and kitchen utensils all feature materials made of NUREL polyamide and PBT compounds.

Electrical and electronic

NUREL PA, PBT, PET, PBT/PET and PP compounds are present in parts and components of electrical and household appliances. Parts molded with Promyde®, Proxylene®, Olexene®, or Recomyde® can be found in food processors, white goods such as refrigerators, washing machines and dryers.

OTHERS SOLUTIONS

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter