INDUSTRIAL

Polyamide 6 for industrial applications

The industrial sector demands special performance to meet the most demanding efficiency, durability and strength requirements. Promyde® and Recomyde® polymers and composites provide technical and value solutions in the manufacture of industrial machinery and components.

From the idea to the part, at every stage of the project, our R&D team supports our customers by developing polyamide grades adapted to their needs, technical requirements and production costs. From food contact grades to highly modified grades with low temperature impact.

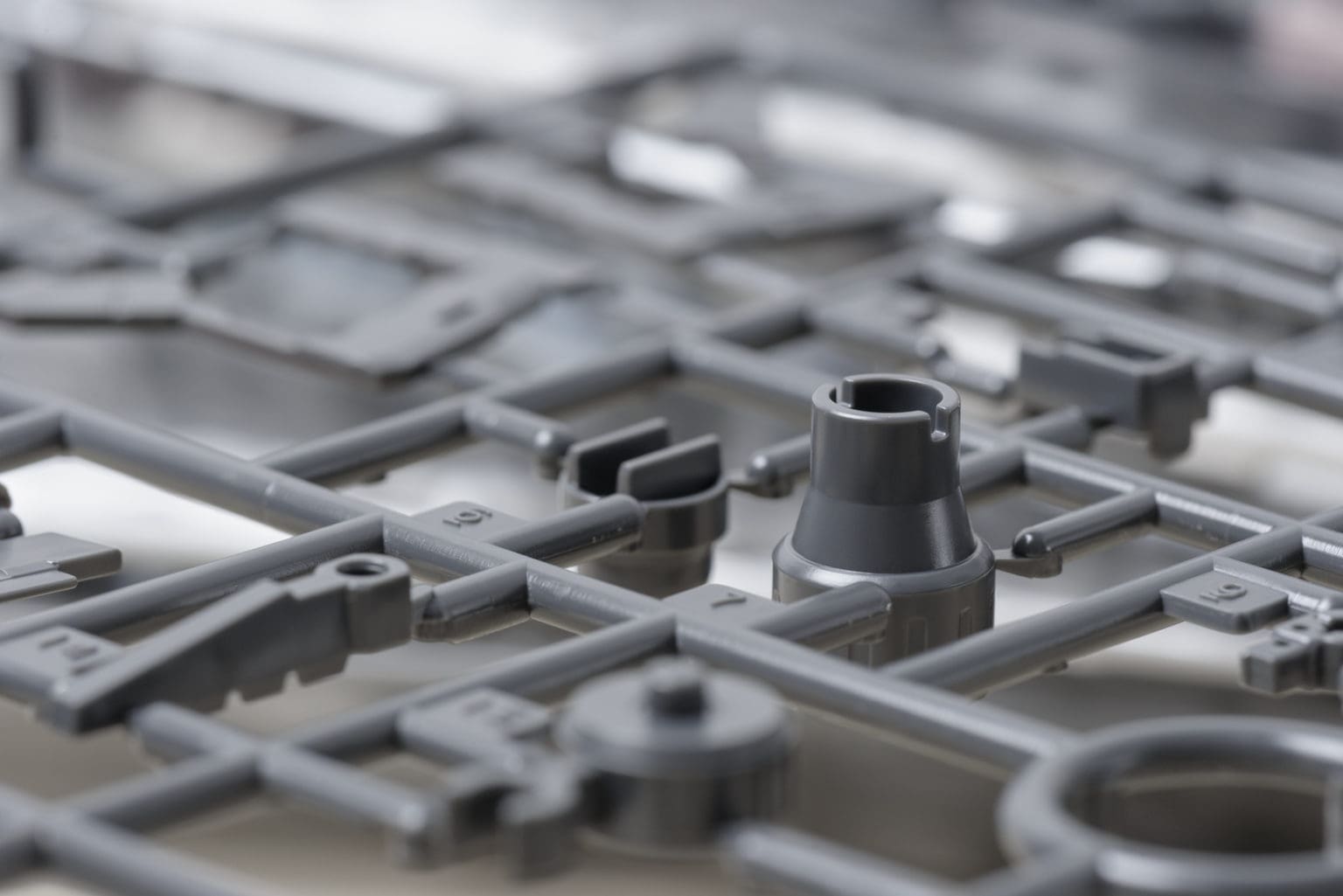

The outstanding properties of our range of PA6 compounds have established themselves as irreplaceable materials in the construction of machine components and mechanisms, performing satisfactorily over a wide temperature range for both injection molding and extrusion applications.

PROMYDE®: HIGH PERFORMANCE POLYAMIDES

Promyde® provides efficient solutions for every need through a wide range of products. Our polyamides 6 and 66 are modified with special properties or reinforced to suit the requirements of each application.

Our glass fiber reinforced grades and/or enhanced impact properties allow for excellent surface finishes while conferring high mechanical performance in almost any temperature range of use, as well as in extreme environmental conditions and food contact requirements.

WIDE RANGE OF POLYAMIDES FOR INDUSTRIAL PROPERTIES

- Impact resistance even at low temperatures

- From high stiffness to elasticity

- Abrasion resistance for extended durability

- Dimensional stability due to low temperature processing

- Excellent surface finish on reinforced and unreinforced grades

- Weight reduction solutions of our WR range

- High density grades are available

- Electrical and magnetic conductivity and shielding

- Cost reduction in energy consumption and cycle time with High Flow polyamide

- Color range according to customer’s request, including grades with enhanced transparency

- Customized materials for your special requirements

- Recomyde: recycled polyamide 6 and 66 compounds.

WIDE RANGE OF POLYAMIDES FOR INDUSTRIAL PROPERTIES

- Impact resistance even at low temperatures

- From high stiffness to elasticity

- Abrasion resistance for extended durability

- Dimensional stability due to low temperature processing

- Excellent surface finish on reinforced and unreinforced grades

- Weight reduction solutions of our WR range

- High density grades are available

- Electrical and magnetic conductivity and shielding

- Cost reduction in energy consumption and cycle time with High Flow polyamide

- Color range according to customer’s request, including grades with enhanced transparency

- Customized materials for your special requirements

- Recomyde: recycled polyamide 6 and 66 compounds.

Solutions

Surface Finish

Our range of reinforced PA6 grades, is designed to deliver a superior surface finish while maintaining high mechanical performance. It is ideal for visible or aesthetic components. Additionally, our PP compounds include talc-reinforced grades and scratch-resistant options, suitable for technical applications where appearance also matters.

Hydrolysis resistant

NUREL provides PA6 and PBT grades with high hydrolysis resistance, specifically developed to withstand exposure to moisture, coolants, fuels, oils and chemicals, even in harsh environments and elevated temperatures.

High flow

Our High Flow types deliver outstanding mechanical performance and greater production efficiency. They are especially recommended for parts with complex geometries and to improved surface finish quality.

Improved transparency

NUREL has modified PA6 crystallization to offer a range of transparent, strong, and durable materials, ideal for injected parts requiring high transparency.

Flame Retardant

Flame resistant grades that meet the most demanding requirements, from V2 to V0 in UL94 and a GWFI of up to 960º. Halogen-free solutions and EN45545 grades available.

Electromagnetic shielding (EMI)

We offer PA and PBT compounds engineered to absorb electromagnetic radiation or to be functionalized with electromagnetic charge.

Magnetic Detection

The new electromagnetic polyamide compounds can be detected and removed using magnets, while retaining the outstanding properties of PA6.

UV Resistance

To increase the lifetime of parts exposed to sunlight, we offer compounds with UV resistant properties.

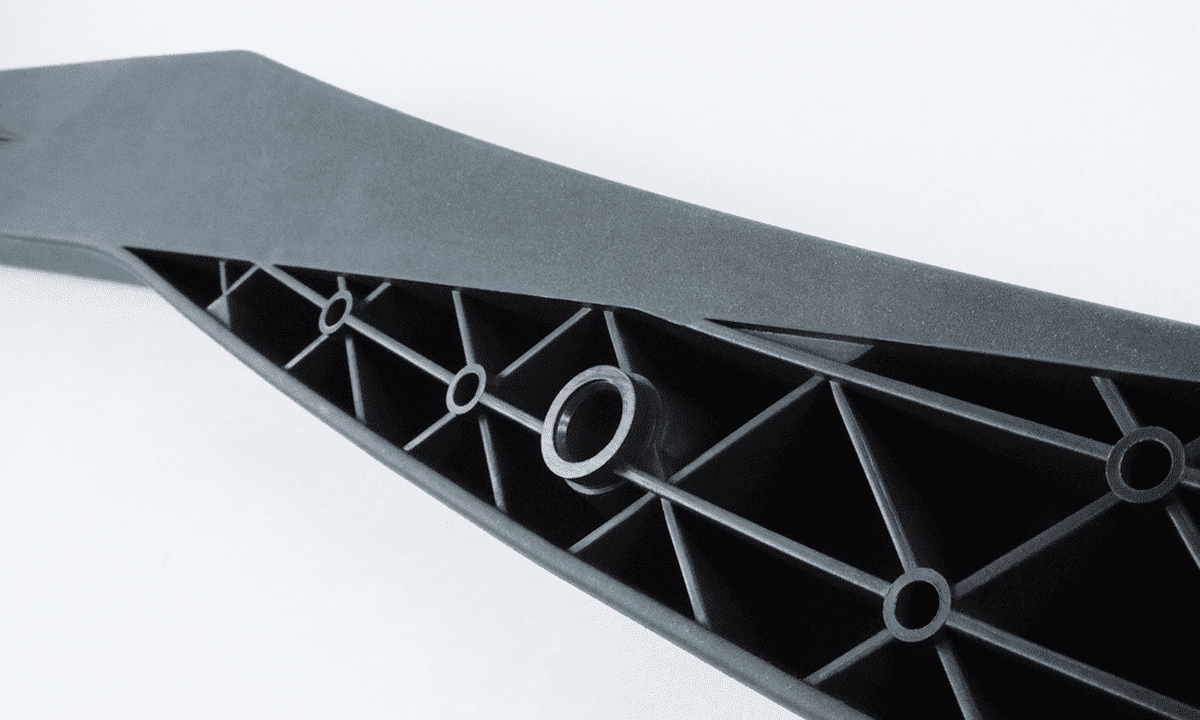

Weight reduction

We offer a wide range of compounds up to 20% lighter, thanks to reinforcements with glass fibers, glass beads, minerals, and nanoclays, without compromising performance.

High Viscosity

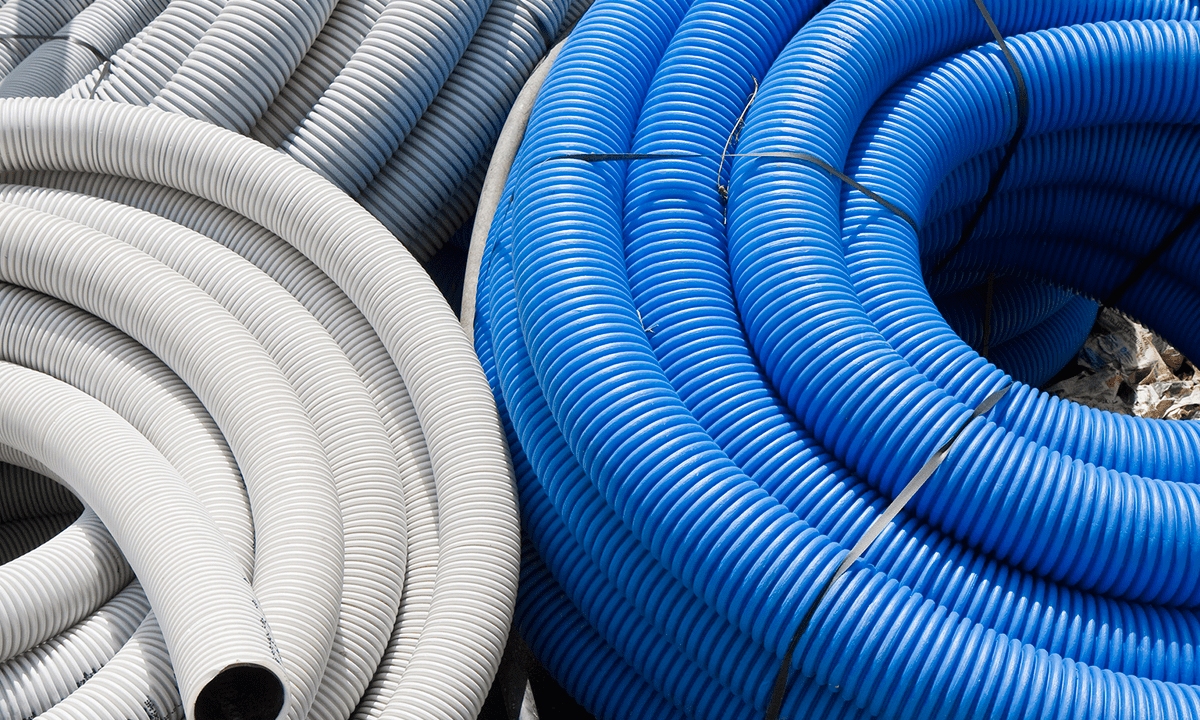

NUREL offers high viscosity grades in both polyamide for extrusion blow molding and extrusion processes and PBT for extrusion, pipe, cable and profile applications.

Surface Finish

Our range of reinforced PA6 grades, is designed to deliver a superior surface finish while maintaining high mechanical performance. It is ideal for visible or aesthetic components. Additionally, our PP compounds include talc-reinforced grades and scratch-resistant options, suitable for technical applications where appearance also matters.

Hydrolysis resistant

NUREL provides PA6 and PBT grades with high hydrolysis resistance, specifically developed to withstand exposure to moisture, coolants, fuels, oils and chemicals, even in harsh environments and elevated temperatures.

High flow

Our High Flow types deliver outstanding mechanical performance and greater production efficiency. They are especially recommended for parts with complex geometries and to improved surface finish quality.

Improved transparency

NUREL has modified PA6 crystallization to offer a range of transparent, strong, and durable materials, ideal for injected parts requiring high transparency.

Flame Retardant

Flame resistant grades that meet the most demanding requirements, from V2 to V0 in UL94 and a GWFI of up to 960º. Halogen-free solutions and EN45545 grades available.

Magnetic Detection

The new electromagnetic polyamide compounds can be detected and removed using magnets, while retaining the outstanding properties of PA6.

Electromagnetic shielding (EMI)

We offer PA and PBT compounds engineered to absorb electromagnetic radiation or to be functionalized with electromagnetic charge.

Weight reduction

We offer a wide range of compounds up to 20% lighter, thanks to reinforcements with glass fibers, glass beads, minerals, and nanoclays, without compromising performance.

UV Resistance

To increase the lifetime of parts exposed to sunlight, we offer compounds with UV resistant properties.

High Viscosity

NUREL offers high viscosity grades in both polyamide for extrusion blow molding and extrusion processes and PBT for extrusion, pipe, cable and profile applications.

Applications

Reinforced Structural Parts

Vehicle structures, such as handgrips, require technical solutions with high fluidity and a good surface finish, which also allow efficient heat dissipation to ensure optimum function and resistance under demanding conditions.

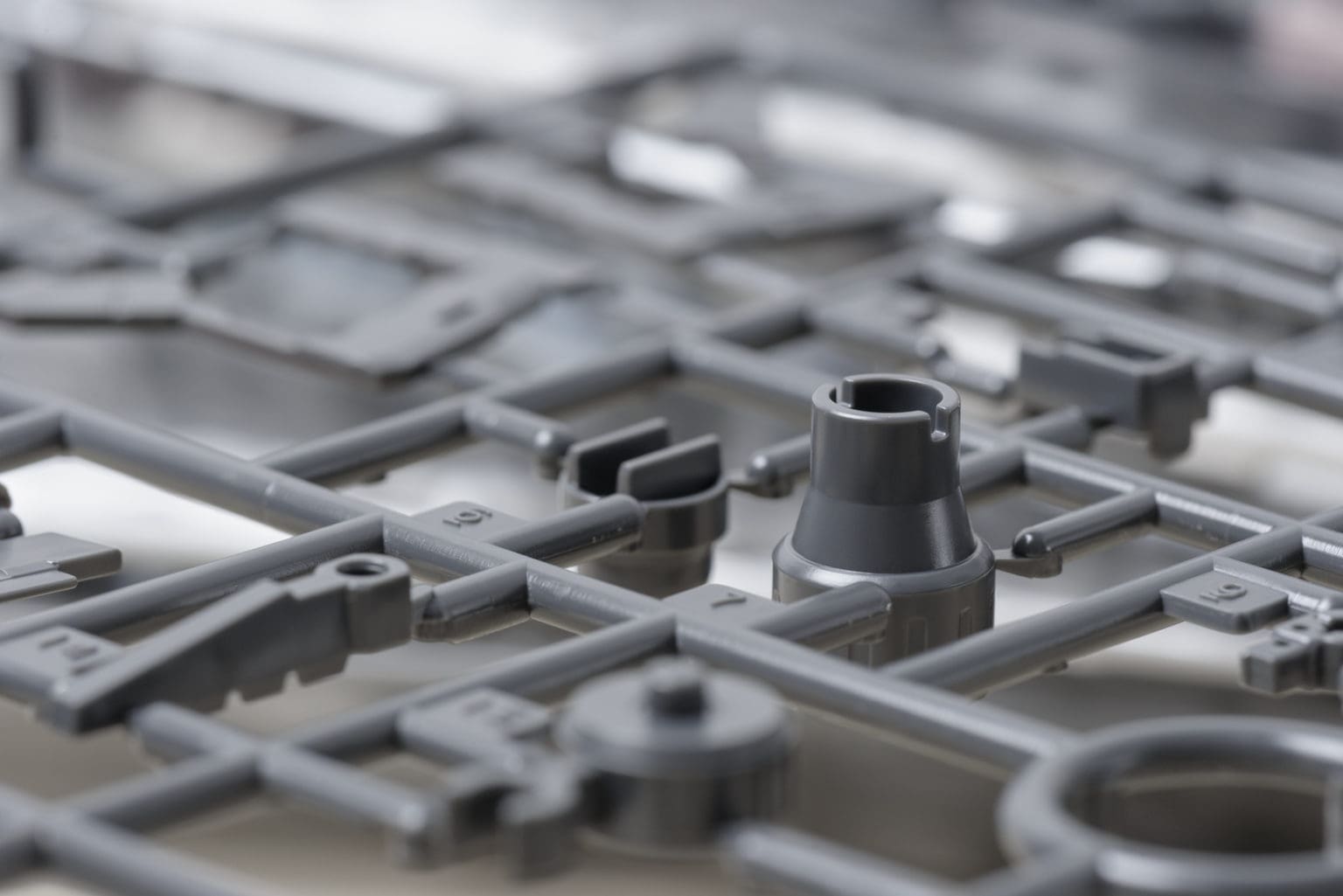

Bearings, gears, components and accessories

Abrasion resistant, Promyde B40 can be used to manufacture essential parts in printing machines, such as rollers.

Casings and protections

PROMYDE's polyamide compound housings and protections offer exceptional thermal and mechanical stability, enabling them to endure high loads and safeguard against impacts, vibrations, and harsh substances, even in demanding conditions

Corrugated pipes

Promyde B33 is commonly used for corrugated pipes of this diameter, and Promyde B36 and B38 for larger diameters.

RELATED MARKETS

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter