POLYAMIDE 6 AND COPOLYAMIDES FOR ITS PRODUCTION OF BOPA FILM

Biaxially oriented polyamide films (BOPA) are very thin structures that provide a high barrier and excellent mechanical properties (puncture and tear resistance).

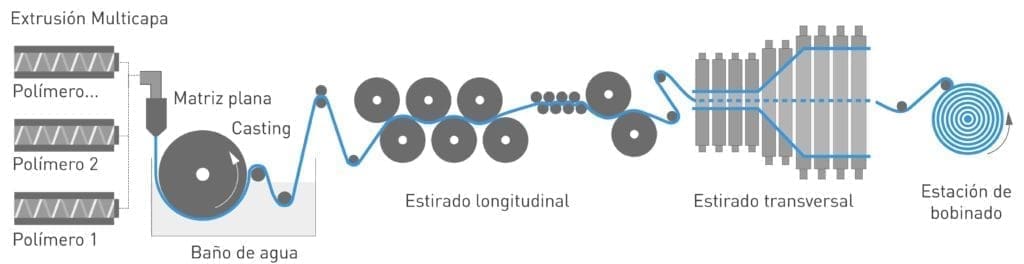

Promyde® offers a wide range of polymers to suit all BOPA film processing technologies for both simultaneous and sequential orientation equipment.

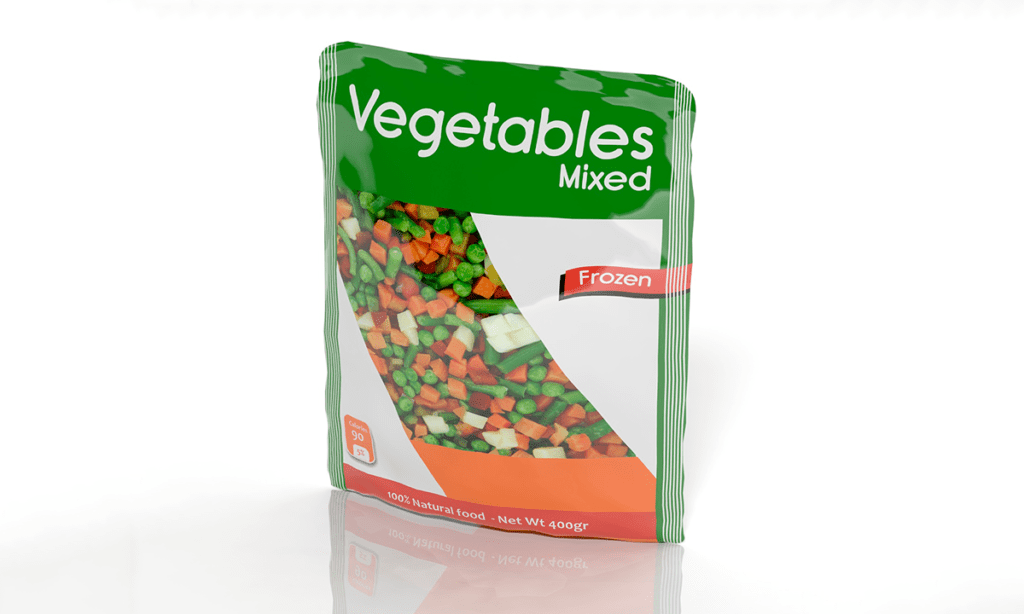

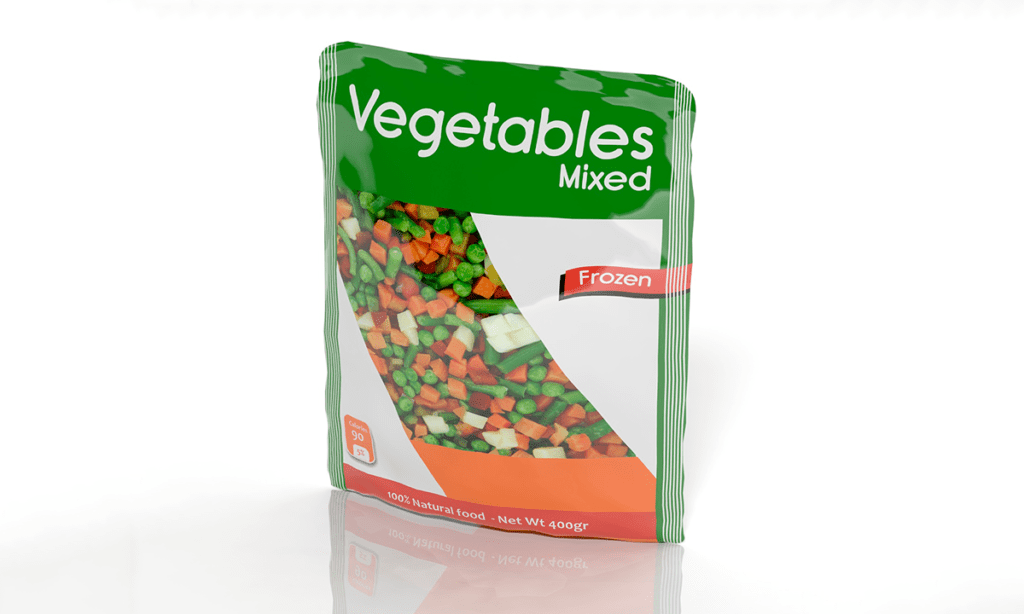

Polyamide 6 is used in food packaging due to its high barrier to oxygen and other gases, in addition to avoiding contamination of aromas and flavors. BOPA extrusion grades of Promyde offer thermal stability and compatibility with other materials used in lamination.

With our range of products specially designed for BOPA extrusion, we offer high quality and excellent processing with the lowest moisture and free monomer contents in the market.

This process is especially recommended for the packaging of frozen products, tray lids and vacuum packaging bags.

PROMYDE PA6 FOR BOPA EXTRUSION

Promyde offers polyamide 6 with a viscosity of 3.3 with or without lubrication. For sequentially oriented equipment, it is recommended to use the lubricated grade.

SPECIFIC PROPERTIES FOR BOPA FILM

- Low moisture content & monomer

- Improved gas barrier (O2, CO2,…) aromas and chemicals.

- Availability of grades with increased CO2 permeability.

- Good optical properties, extremely transparent grades

- Special grades with sealing properties.

- High temperature HT resistance, available for sterilization treatments.

SPECIFIC PROPERTIES FOR BOPA FILM

- Low moisture content & monomer

- Improved gas barrier (O2, CO2,…) aromas and chemicals.

- Availability of grades with increased CO2 permeability.

- Good optical properties, extremely transparent grades

- Special grades with sealing properties.

- High temperature HT resistance, available for sterilization treatments.

Download our catalogues

Promyde - Film

Solutions

Barrier solutions

Films for sealing

Low curling films

MARKETS

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter