Polyamide 6 and PBT for Extrusion

PA6 extrusion grades

Our expertise makes NUREL a reliable supplier in polyamide 6 with a global presence in multiple extrusion market segments, from high tenacity yarns to profiles and pipes and from extrusion blow moulding to cable jacketing. Polymer chain modification during polymerization, along with the unique additive packages we offer, are the key elements for our wide Promyde extrusion portfolio.

Polymer chain modification during polymerization, along with the unique additive packages we offer, are the key elements for our wide Promyde extrusion portfolio. With sophisticated laboratories for analyzing both chemical and mechanical properties, along with parallel synergies with other polymerization companies within the SAMCA Group, NUREL can take customer requests for new developments from laboratory stages to full scale industrial production in months.

Promyde® PA6 Additive Packages

Our wide product range provides different solutions for each application, from relative viscosity 3.0 up to 5.0 and wide additive package.

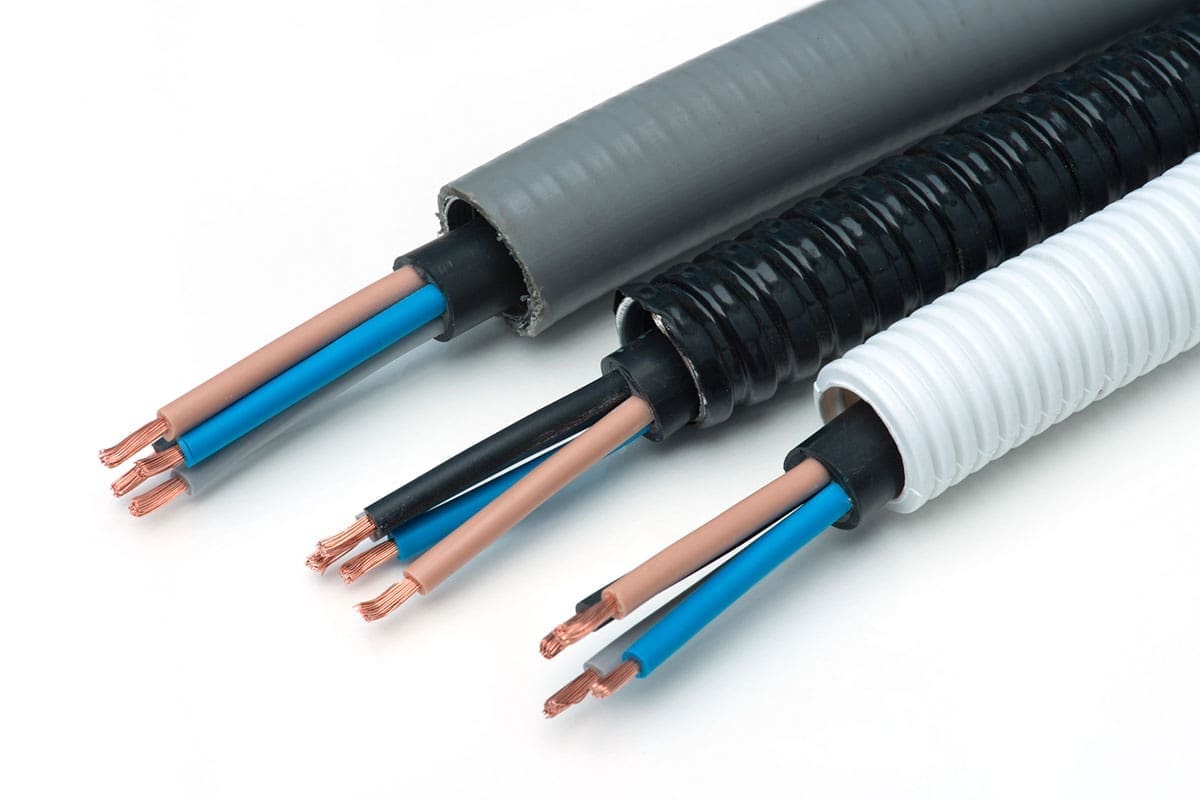

- UV protection and heat stabilizers to increase lifetime for outdoor applications such as electrical conduits.

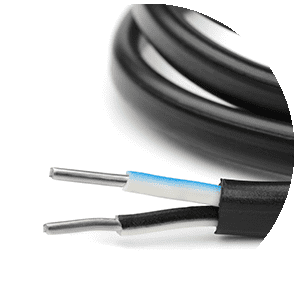

- Impact modified product range to improve toughness on tubes and cables.

- Glass fiber reinforced PA6 to enhance stiffness on profiles and bars.

- Flame retardant for electrical applications.

- Colouring in RAL colour cards and customized colour matching.

- High flexibility polyamide.

- Other additives such as lowering coefficient of friction agents and conductive additives are available upon request.

Promyde® PA6 Additive Packages

Our wide product range provides different solutions for each application, from relative viscosity 3.0 up to 5.0 and wide additive package.

- UV protection and heat stabilizers to increase lifetime for outdoor applications such as electrical conduits.

- Impact modified product range to improve toughness on tubes and cables.

- Glass fiber reinforced PA6 to enhance stiffness on profiles and bars.

- Flame retardant for electrical applications.

- Colouring in RAL colour cards and customized colour matching.

- High flexibility polyamide.

- Other additives such as lowering coefficient of friction agents and conductive additives are available upon request.

Proxylene PBT for extrusion

PBT is widely utilized in a range of extrusion applications due to its favorable characteristics, including remarkable mechanical strength, dimensional stability, chemical resistance, and electrical insulation properties. One notable application of PBT is its use in the extrusion of cables and wires. Thanks to its exceptional electrical insulation properties, heat resistance, and impressive mechanical strength, it is well-suited for extruding fiberglass cables.

Our high viscosity grades of Proxylene can be extruded into bars and profiles used in industries such as construction, automotive and electrical. Additionally, PBT finds utility in the extrusion of pipes and tubes for automotive, plumbing, and chemical processing sectors, owing to its exceptional chemical resistance and dimensional stability.

Furthermore, PBT’s heat resistance, durability, and minimal warping characteristics render it a suitable material for 3D extrusion, enabling the production of functional prototypes and end-use parts.

Solutions

Reinforced solutions

Our mineral filler, glass fiber and carbon fiber reinforced solutions achieve the best performance for injection molding and extrusion applications.

Thermal stability

Special copolyamides are available to withstand high temperatures for long periods of time, maintaining excellent mechanical properties. In addition, we have metal-free grades that are perfect for avoiding galvanic corrosion.

UV Resistance

To increase the lifetime of parts exposed to sunlight, we offer compounds with UV resistant properties.

High Viscosity

NUREL offers high viscosity grades in both polyamide for extrusion blow molding and extrusion processes and PBT for extrusion, pipe, cable and profile applications.

Metal replacement

Orange RAL 2003

Recyclable

BIODEGRADABLE

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter