Biodegradable PA

Biodegradable PA6 : facing sustainable challenges

NUREL offers a solution specially designed for polyamide products discarded in landfills at the end of their useful life: Promyde BIO. This new PA 6 polymer biodegrades at the end of its life, transforming into methane which, when properly captured, can be converted into green energy. Unlike oxodegradable solutions, Promyde BIO can biodegrade in both aerobic and anaerobic environments without fragmenting due to oxygen or UV rays.

Biodegradable* PA 6 for film and filament extrusion and injection molding.

NUREL’s biodegradable polyamide 6 maintains the standard properties of PA6, degrading only when it comes into contact with an active biological environment. Similarly, it can be processed using standard production processes, maintaining its recyclability. In addition, Promyde BIO is suitable for food contact.

- Biodegradable* in soil

- Biodegradable* in landfills

*Note: claims regarding biodegradability must always refer to a recognised standard. From 2022 onwards, the claim ‘biodegradable’ will not be accepted in some territories. Please consult the latest regulations for each territory.

Promyde BIO Applications

Polyamide 6 (PA 6) is used for its mechanical properties and, in many applications, cannot be replaced by other materials.

However, polyamide is a minority plastic which, due to its technical requirements and use in complex structures such as multilayer packaging or overmoulded parts, does not usually enter recycling channels. At the end of their useful life, these products are discarded and end up in landfills, where plastics can take hundreds of years to degrade.

PROMYDE® Bio offers a sustainable solution to this problem, as it promotes the biodegradation of PA-based parts.

Biodegradable polyamides 6 are recommended for:

- Applications where the use of PA is required.

- Multi-material structures such as complex packaging or overmoulded parts.

- Injected parts for sectors such as automotive (electric cars) and household appliances.

Promyde Bio and carbon footprint

The final disposal/waste system plays an important role in the carbon footprint of any material.

The final disposal/waste system plays an important role in the carbon footprint of any material.

The impact of the carbon footprint must be analyzed according to each disposal scenario.

The main environmental impact of Promyde BIO is related to its landfill management, where the resulting methane is captured and converted into energy, resulting in a carbon footprint reduction of up to 15%.

"Only 32.5% of plastic is recycled worldwide":

19% outside the EU

PROMYDE BIO: Main features

- Does not decompose with oxygen or UV rays

(Not oxodegradable) - Maintains the properties of PA6

- No loss of physical properties or service life

- Only degrades when it comes into contact with an active biological environment

- Can be processed using standard PA6 production methods

- Maintains recyclability

- Food contact

Carbon footprint impact of PROMYDE BIO

- The final disposal/waste system plays an important role in the carbon footprint of any material

- The carbon footprint impact must be analysed according to each disposal scenario

- The primary carbon impact of PROMYDE® BIO is related to landfill disposal, where the resulting methane is managed and converted into energy, providing a carbon reduction of approximately 15%

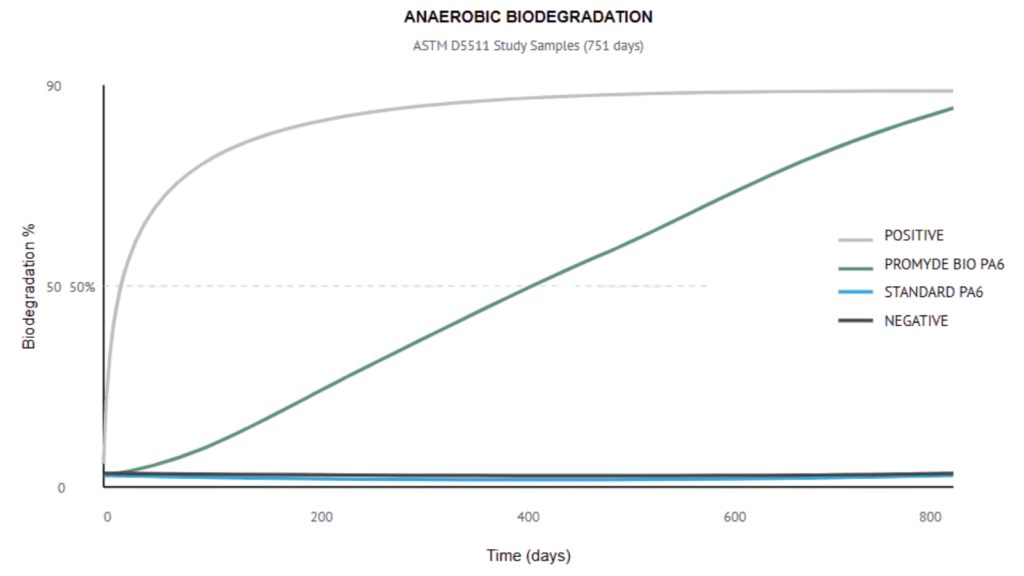

Anaerobic biodegradation

Anaerobic biodegradability according to ASTM D5511. After 751 days: Up to 84.2% biodegradation

Anaerobic biodegradation of PA6 according to ASTM D5511

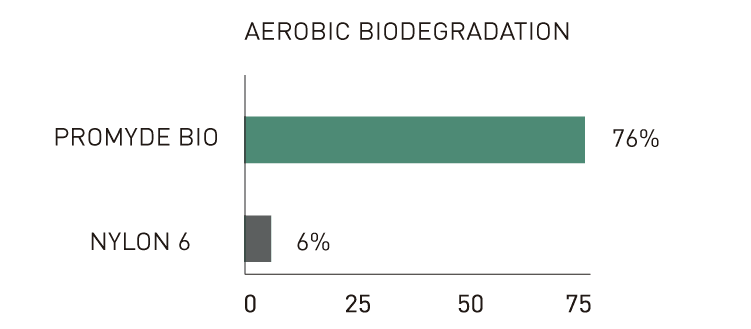

Aerobic biodegradation of PROMYDE® BIO according to ISO 17556:2020

Aerobic biodegradation

NUREL does not support the dumping of waste of any kind. In case of improper disposal of plastic waste, PROMYDE® BIO also biodegrades in the soil.

Thus, aerobic biodegradation is the degradation of organic matter by microorganisms in oxygen environments, such as soil.

Aerobic certification, according to ISO 17556:2020, establishes 76% biodegradation after 90 days in active soil.

Download our catalogues

Promyde Bio

PROMYDE BIO FAQS

ANSWERS TO THE MOST FREQUENTLY ASKED QUESTIONS ABOUT PROMYDE BIO

1. What are the main properties of Promyde BIO?

Promyde BIO retains the same physical properties and strength as standard grades of Promyde. Your products will retain an indefinite shelf life, unaffected by light, heat, moisture or stress, until they are disposed of in an environment with microbial activity (such as landfills or active soils) where they will biodegrade into biomass, CO₂ and biogas.

2. How does Promyde BIO compare to other polymers?

| Product | Degradation by light, heat, moisture or mechanical stress | Biodegradation in landfills (anaerobic) | Soil biodegradation (aerobic) | Residues |

|---|---|---|---|---|

| Promyde BIO | No | 1–15 years | 1–10 years | Biomass, CO₂, biogas |

| Conventional polymers | No | > 100 years | > 100 years | Plastic resin |

| Compostable polymers | Yes | 1–15 years | 1–10 years | CO₂, biogas |

| Oxodegradable polymers | Yes | > 100 years | > 100 years | Microplastics, metal ions, heavy metals |

3. What is the difference between biodegradable, compostable and degradable plastics?

- Biodegradable plastic: degrades through the action of microorganisms in aerobic (with oxygen) or anaerobic (without oxygen) environments, within an unspecified period of time.

- Compostable plastic: decomposes under composting conditions into CO₂, water, inorganic compounds and biomass, complying with standards such as EN13432, within a specific period of time.

- Degradable plastic: undergoes chemical changes under environmental conditions that deteriorate its physical properties, usually initiated by oxygen, UV light or heat. They begin to degrade from the moment they are manufactured, reducing their useful life. Oxo-degradable polymers are banned in Europe.

4. Do traditional plastics biodegrade, and how does Promyde BIO do so?

Traditional plastics are durable and not designed to biodegrade easily. Their structure is based on long chains of carbon atoms that provide strength and durability, but make it difficult for microorganisms to metabolise them.

5. How does Promyde BIO biodegrade?

Promyde BIO accelerates biodegradation thanks to its advanced technology, which promotes the accumulation of microorganisms and facilitates the acclimatisation and production of enzymes that enable their metabolisation.

6 Does Promyde BIO biodegrade while in storage?

No. Promyde BIO requires an active microbial environment (such as a landfill or biologically active soil) to biodegrade.

It does not degrade in warehouses, offices, or on shelves.

7. How long does it take for Promyde BIO to biodegrade?

The biodegradation time depends on factors such as surface area, mass, thickness and environmental conditions.

Under optimised conditions:

- Up to 24.7% biodegradation in 160 days under anaerobic conditions.

- Up to 95.6% biodegradation in 348 days in active soil.

8. What tests validate the biodegradation of plastics in a landfill?

Laboratories use standardised tests such as:

- ASTM D5511 → short-term biodegradability.

- ASTM D5526 → long-term simulation of landfill conditions.

Each test has a different focus and limitations, so their results should not be compared directly.

9. Can Promyde BIO be used in food contact applications?

Yes. If Promyde’s standard grade complies with FDA and EU regulations for food contact, Promyde BIO will also be suitable.

10. What does the ISO 17556 standard consist of?

ISO 17556 defines the methodology for testing the biodegradation of materials in soil.

- It is preferable to use the material in powder form, although it can also be used in film, fragment, chip or profile form.

- 100–300 g of material is used, with a maximum size of 5×5 mm.

- To compare different polymers, it is recommended to use the same format.

- The greater the contact surface area of the material, the higher the biodegradation rate.

11. In which applications is Promyde BIO the ideal material?

Promyde BIO is designed for applications with high technical requirements where compostable polymers are not sufficient.

Particularly suitable for:

- Short-life applications.

- End-of-life parts that are not effectively recycled or properly disposed of.

Other sustainable polyamide solutions

Recycled

Recyclable

Biobased and Biocircular

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter