EASY PROCESSING & FLEXIBILITY

SLOW-CRYSTALLISING POLYAMIDE FOR FLEXIBLE FILM APPLICATIONS

PA6 Promyde BF36SC is the latest addition to our high-performance polyamide range.

Specifically developed for applications requiring deep thermoforming, high transparency, and excellent mechanical strength, this grade represents a reliable alternative to conventional PA6 solutions.

This new development delivers enhanced processability for CAST and BLOWN extrusion, offering exceptional flexibility.

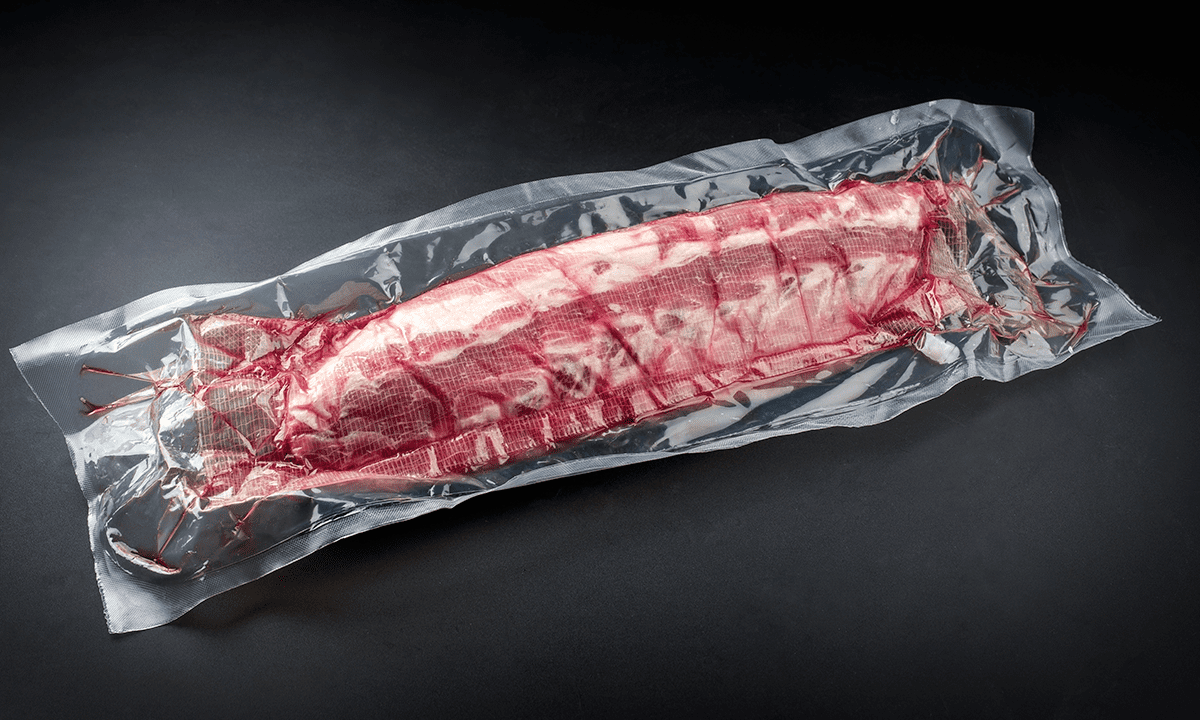

Promyde® BF36SC is ideal for sausage casings and vacuum bags, providing higher performance, flexibility, and processability compared to standard PA6 grades.

Do you want to know more?

AVAILABLE GRADES

- Promyde BF36SC L: Lubricated – reference material for blown film and three-bubble technology.

- Promyde BF36SC LN: Lubricated and nucleated – suitable for cast film, blown film, and extrusion lamination.

MAIN PROPERTIES

Lower melting point (210 °C vs. 220 °C), facilitating easier processing.

Slow crystallisation behaviour, resulting in excellent transparency and conformability.

MELTING POINT

TEAR RESISTANCE (N/mm)

TRANSPARENCY

ADVANTAGES COMPARED TO PA6

- Greater tear resistance

- Higher elongation at break

- Improved puncture resistance and reduced opacity

| BF40 (PA6) | BF36SCL | |

|---|---|---|

| Thickness, microns | 50 | 50 |

| Module MD, MPa | 2.000–2.500 | 1.500–2.000 |

| Stress at break MD, MPa | 50–55 | 50–55 |

| Strain at break MD, % | 150–200 | 250–300 |

| Tear strength MD, N/mm | 15–20 | 30–40 |

| Tear strength TD, N/mm | 15–20 | 30–40 |

| Puncture force, mJ | 20–25 | 25–30 |

| Puncture energy, mJ | 10–13 | 13–16 |

| Haze, % | 10 | 5 |

Applications

VACUUM PACKAGING BAGS

Polyamide (PA) vacuum bags are extensively used for vacuum-sealing fresh meat, fish, vegetables, cheese and ready-to-eat meals. This packaging solution significantly extends product shelf life by preventing the growth of spoilage-causing microorganisms.

MATERIALS FOR CASING & SMOKED PRODUCT CASING

NUREL offers a specialised range of Promyde PA6 grades, engineered for high-performance casing applications, together with the ENOXITE SMOKE series – an advanced range of ultra-high barrier polymers – designed to preserve the quality and extend the shelf life of cooked meats and sausages.

Related markets

Packaging

Polyamides are widely used in the packaging industry due to their excellent mechanical strength and barrier properties, as well as their ability to deliver a premium finish with high gloss and transparency.

OTHER SOLUTIONS

Do you want to know all the news of Nurel Polymers?

Subscribe to the newsletter