PA AND PBT COMPOSITES WITH THERMAL STABILIZATION

Thermostabilized polymers, such as PBT and PA6, are used in a variety of applications where their ability to withstand elevated temperatures is crucial. NUREL offers reinforced and unreinforced PA and PBT compounds with specific formulations to ensure that they maintain their mechanical properties and resist degradation even in demanding thermal environments.

PBT and PA6 are favoured choices due to their excellent heat resistance, dimensional stability, and mechanical strength. They find extensive use in industries such as automotive, electrical and electronics, appliances, and industrial equipment, where reliable performance at high temperatures are essential.

Polyamide thermally stabilized and prevention of galvanic corrosion

With the development of Promyde® HSA heat stabilized compounds range, NUREL expands its portfolio with a wide range of thermally stabilized PA6 that includes HS, HSA grades without copper salts and HSA HR grades with hydrolysis resistance.

Thanks to this new intrinsic thermal stabilization, Promyde’s thermally stabilized polyamides offer a unique thermal resistance of up to 185°C, avoiding galvanic corrosion in electrical components thanks to their halogen and metal-free stabilization, with an halogen content less than 50ppm.

Promyde HSA innovative thermal stabilization solution can be applied to all Promyde PA6 grades from 10 up to 60% fiber content.

Promyde HSA is perfect for applications where a thermally stabilized PA6 grade is required to meet higher temperature resistance and other requirements. Its metal-free thermal stabilization is increasingly in demand to protect sensitive electronic components from galvanic corrosion to prevent potential failures.

Promyde 6 HSA polyamide polymers demonstrate significantly superior mechanical properties over other existing PA66 alternatives available in the market, particularly in terms of aging resistance.

PA Compounds Hi-Performance at Hi-Temperatures

Some properties and advantages offered by Promyde HSA’s range of thermally stabilized polymers are:

- Promyde HSA’s innovative thermal stabilization provides heat resistance up to 185°C in demanding environments.

- An effective Galvanic corrosion protection on electrical equipment

- Halogen and metal-free stabilization package.

- Unreinforced and reinforced up to 60% fiber content

- Superior ageing resistance comparing to PA66

PROXYLENE PBT GF HR Compounds: high heat stability & low moisture absorption

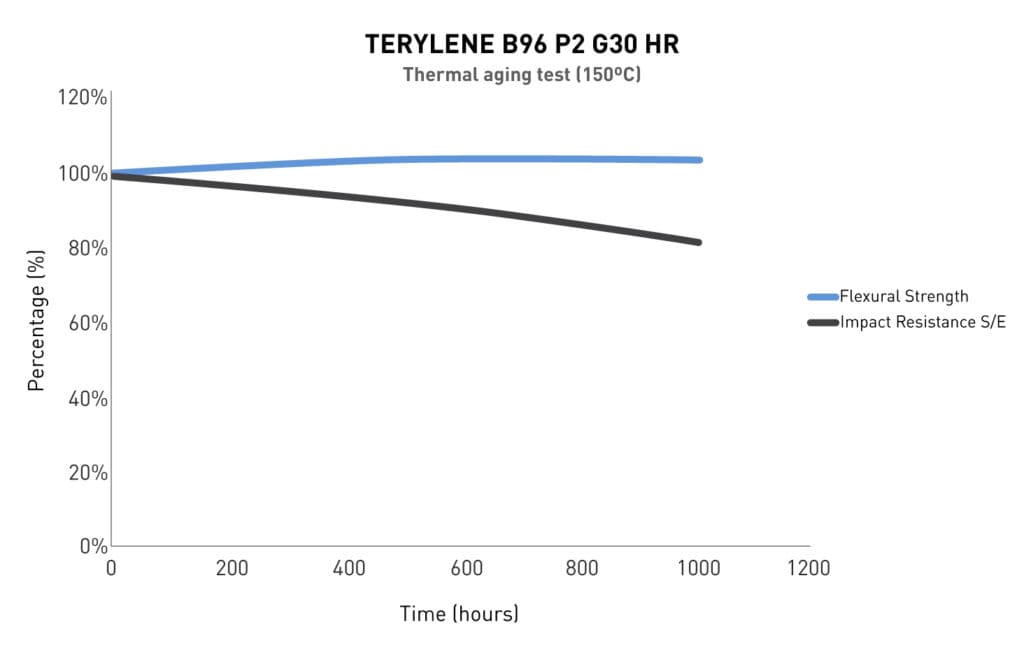

Proxylene PBT HR glass fiber reinforced grades feature improved mechanical properties and long-lasting thermal stabilization compared to standard glass fiber reinforced PBT grades. These special grades are further enhanced by incorporating heat stabilizers into their formulation and polymer chain.

This development improves the material’s resistance to thermal degradation and maintain its mechanical properties at elevated temperatures for long periods of time. It also prevents from degradation reactions, such as oxidation or chain scission, which can occur when the material is exposed to high temperatures for extended periods.

Our PBT HR grades with improved temperature resistance, combined with the limited moisture absorption of the material makes it the material of choice for applications where high temperature resistance is required for long periods of time, and low moisture absorption

Applications

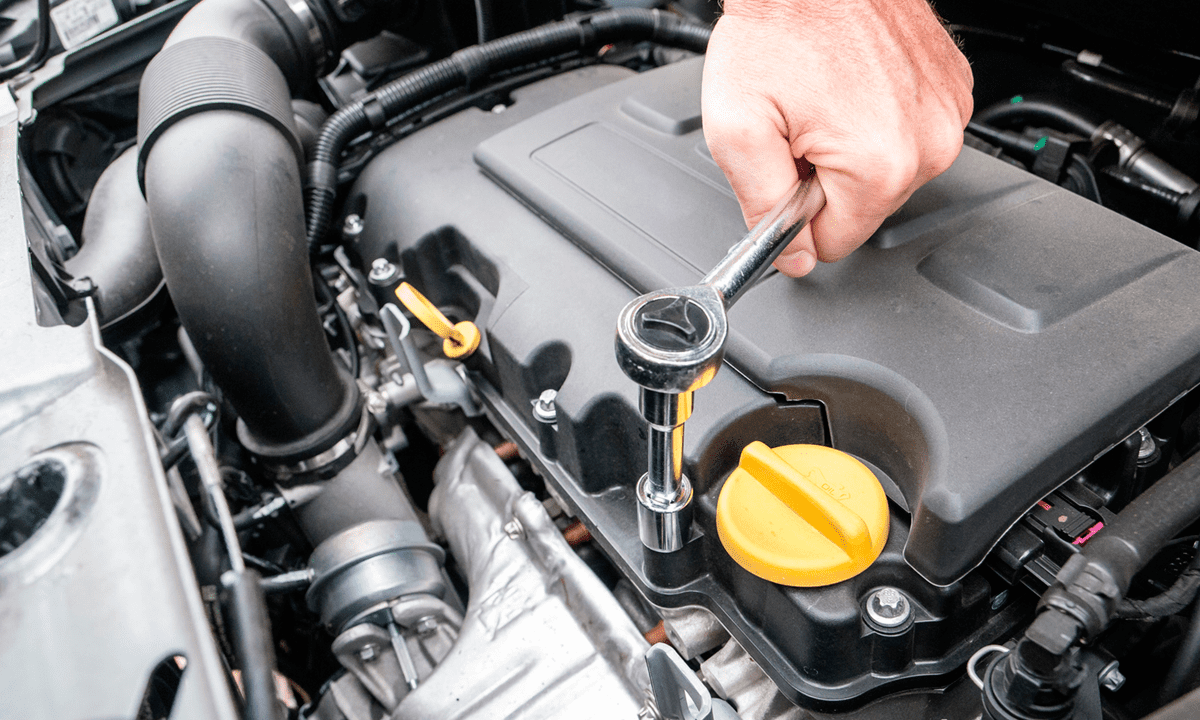

Underhood Applications

The Promyde® range of materials provides solutions for all types of under-hood applications requiring high temperature stability and hydrolysis resistance, while maintaining their mechanical properties.

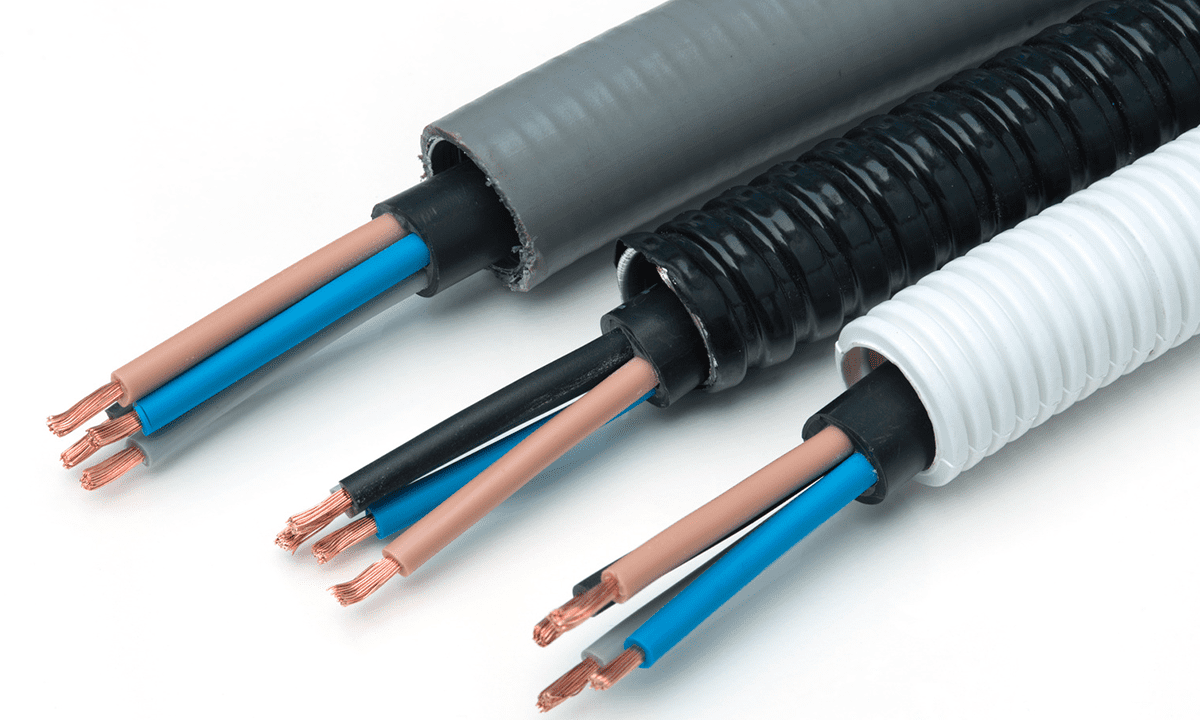

Cable jacketing

At NUREL, we provide heat-resistant, UV-stable and even flame-retardant polyamide and PBT compounds for the production of cables, wires and cable protection.

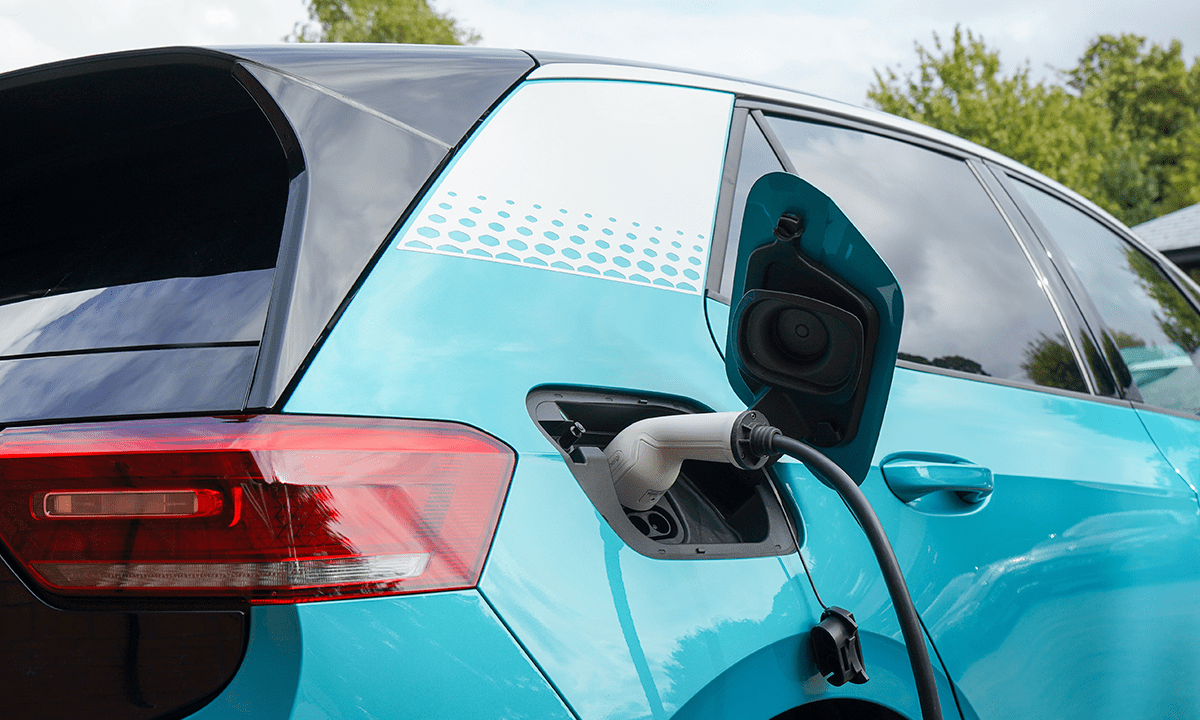

Electric vehicle

NUREL has developed engineered polymers for electric vehicles, improving autonomy, safety and sustainability. Our range of compounds, including PA6, PA66, PBT, PET, PP and PA, recycled PET and PP, offers solutions for interior, exterior, aesthetic finishes and metal replacement components, helping to reduce vehicle weight and ensuring high performance.

Reinforced Structural Parts

Vehicle structures, such as handgrips, require technical solutions with high fluidity and a good surface finish, which also allow efficient heat dissipation to ensure optimum function and resistance under demanding conditions.

RELATED MARKETS

MOBILITY AND AUTOMOTIVE

The mobility sector has always been a leader in mechanical innovation and process optimization. At NUREL, we support this evolution with our range of engineering polymers - PA6, PA66, PBT, PET and PP - designed to respond to the industry's demand for lighter, more sustainable and efficient solutions.

Electrical and electronic

NUREL PA, PBT, PET, PBT/PET and PP compounds are present in parts and components of electrical and household appliances. Parts molded with Promyde®, Proxylene®, Olexene®, or Recomyde® can be found in food processors, white goods such as refrigerators, washing machines and dryers.

Cables and Pipes

Promyde® PA and Proxylene® PBT polymers for UL 83-certified cables such as copper building wire, PVC Nylon tray cable, THHN cable and THWN cable, fiber optic cable, as well as tubes and pipes for cable management systems.

OTHERS SOLUTIONS

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter