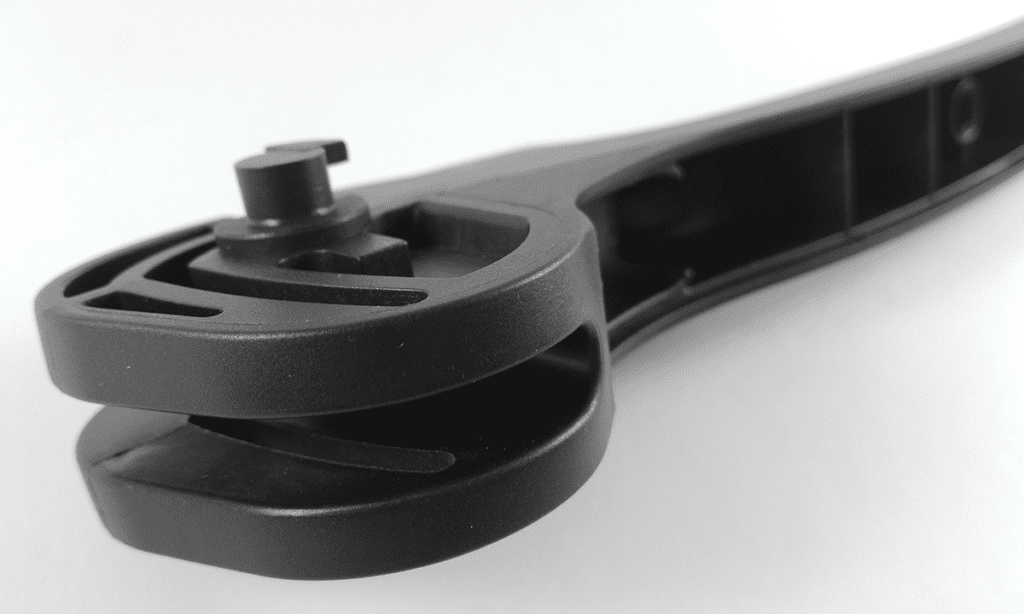

PA 6, 66 and compounds for injection applications

Manufacturing process of injection parts is highly versatile and requires polymers that allow rapid filling and demolding of the parts, high productivity, dimensional stability and a good surface finish. Promyde® polyamides meet all these requirements and, in addition, offer reinforced grades, hydrolysis resistant grades, conductive polyamides and high flame retardant grades. Promyde has developed one of the broadest ranges of polyamide and PA 6 and 6.6 compounds for injection molding on the market.

In addition, NUREL Engineering Polymers also offers PBT, PET and PBT/PET compounds, which under the brand name Proxylene have been specially designed for injection molding parts for the automotive, electrical and electronics industries.

Injection blow process is used for the manufacture of hollow plastic parts in large quantities. Promyde offers optimum grades for this type of application.

Reinforced and unreinforced polyamides 6 & 66 for injection

Non-reinforced Promyde grades are produced at NUREL through a polymerisation process in which additive packages and polymer chain modifications are made combining cost, effectiveness and differential properties. Our products are melted for the first time in the injection machines of our customers.

Reinforced Promyde grades are also produced 100% at NUREL through our in-house compounding and polymerization process. Our PA6 & PA66 compounds guarantee high processing consistency and unparalleled product performance.

OUR OFFER OF COMPOUNDS FOR INJECTION

NUREL, has recently expanded its compounding facilities. This has allowed us to expand our range of PA6 and PA66 products, as well as the launch of a new range of PBT, PET and PBT/PET compounds: Terylene.

In response to a growing demand in the electrical, electronics and mobility sectors, where weight limitation and design requirements are increasingly strong, NUREL is working on the development of new materials with controlled thermal and electrical properties, as well as materials for metal substitution, weight reduction and flame retardancy.

OUR OFFER OF COMPOUNDS FOR INJECTION

NUREL, has recently expanded its compounding facilities. This has allowed us to expand our range of PA6 and PA66 products, as well as the launch of a new range of PBT, PET and PBT/PET compounds: Terylene.

In response to a growing demand in the electrical, electronics and mobility sectors, where weight limitation and design requirements are increasingly strong, NUREL is working on the development of new materials with controlled thermal and electrical properties, as well as materials for metal substitution, weight reduction and flame retardancy.

SOLUTIONS

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter