Wide range of polyamide 6 for extrusion

Polyamide 6 is a polymer that is used thanks to its high performance in extrusion processes for the manufacture of applications with specific requirements, such as packaging and sustainable packaging, synthetic fibers or for the extrusion of cables and semi-finished products.

Thanks to our versatile polymerization lines, state-of-the-art postcondensation units, NUREL offers our Promyde® product range for extrusion, covering grades from relative viscosity 3.3 to 5.0.

Polymer chain modification during polymerization, together with the unique additive packages we offer, are the key elements to our extensive Promyde extrusion portfolio.

PROMYDE PA6 FOR EXTRUSION

One of the main applications of polyamide 6 is the manufacture of films for packaging. Our R&D department has developed a wide range of specific products to provide films with special properties to preserve and extend the shelf life of food, such as solutions with improved oxygen barrier, low curling, and even additivated polyamides for the manufacture of active packaging.

Our integration in fiber and filament extrusion allows us to have an efficient range for the manufacture of mono and multifilaments, as well as new grades for the production of 3D printing filaments.

In addition, Promyde‘s wide range includes specific grades for cable and pipe sheathing extrusion, rod extrusion and sheet and profile extrusion as well as for extrusion blow molding of hollow parts. Available in viscosities up to 5.0.

Viscosities available 3.3, 3.6, 3.8 and 4.0

All grades can be lubricated (L) and/or nucleated (N).

MODIFIED POLIAMIDES FOR EXTRUSION AND EXTRUSION BLOW MOLDING

Our wide range of products provides different solutions for each application, with relative viscosities from 3.0 to 5.0, and different additive packages.

- UV protection and thermal stabilization to increase the lifetime of outdoor applications, such as electrical applications.

- Impact modifiers to improve the strength of pipes and cables.

- Fiberglass reinforcement to improve rigidity in semi-finished products.

- Flame retardant for electrical applications.

- Custom coloring based on RAL.

- Elastomeric additives for flexible pipes.

- Other additives, such as conductive agents, etc.

Extrusion markets

Packaging

Polyamides are used in the packaging industry for their good mechanical properties, barrier properties and for providing a quality finish due to their high gloss and transparency.

Filaments

NUREL offers a wide range of polyamide 6 homopolymers and copolyamides for monofilament applications such as guides for viticulture, fishing nets, cutting lines in lawn mowers, hot melt filaments for adhesives in sportswear and clothing, filaments for 3D printing, etc.

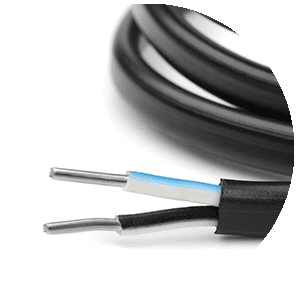

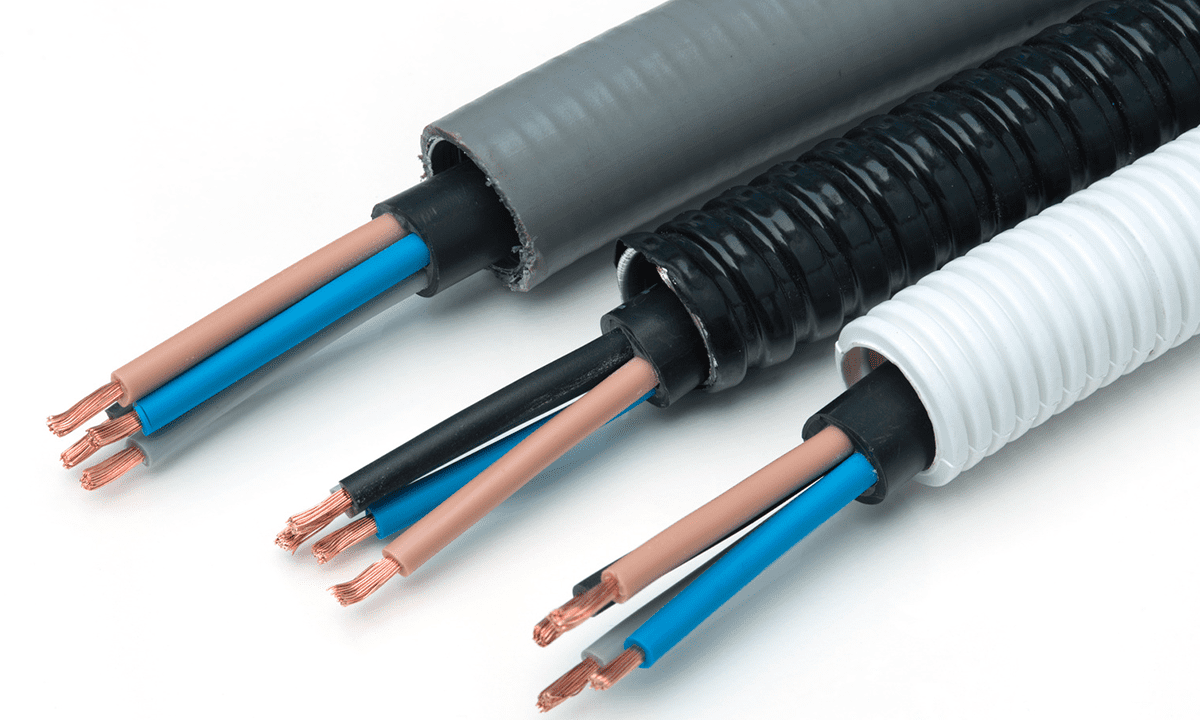

Cables and Pipes

Promyde® PA and Proxylene® PBT polymers for UL 83-certified cables such as copper building wire, PVC Nylon tray cable, THHN cable and THWN cable, fiber optic cable, as well as tubes and pipes for cable management systems.

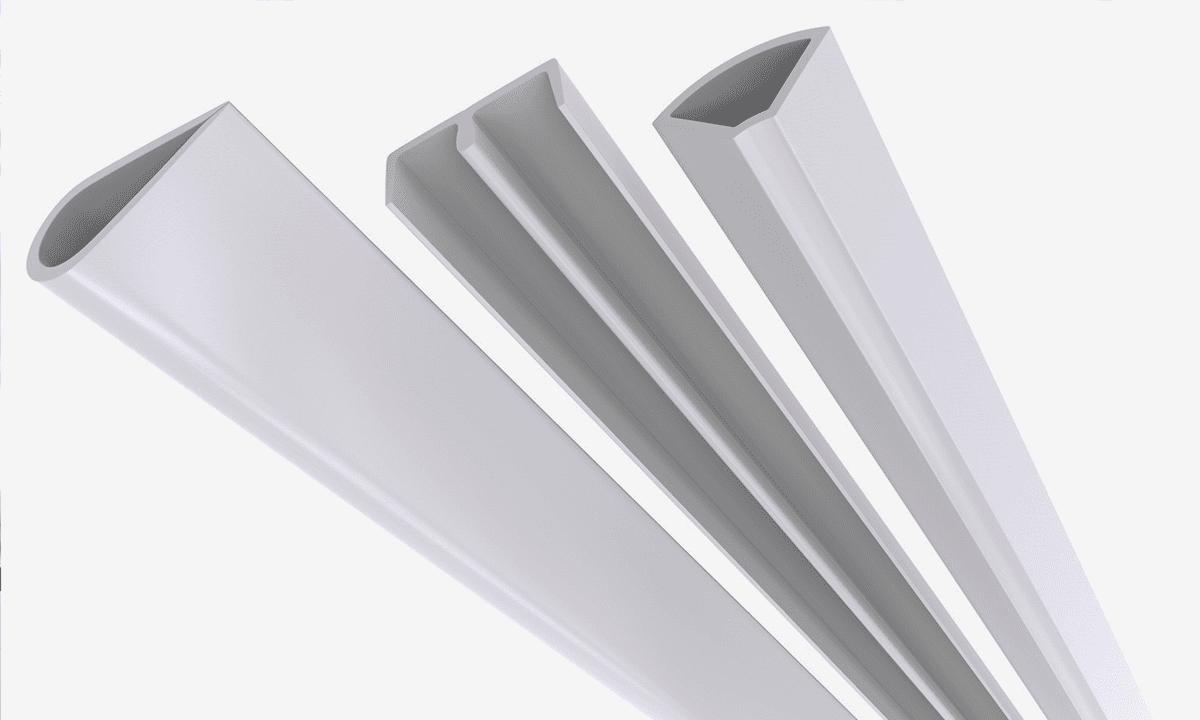

Construction

Polyamides designed by NUREL for use in construction applications provide high durability, corrosion resistance, high resistance to ultraviolet radiation and extreme weather conditions, thus requiring low maintenance, which makes them an efficient and economically attractive option.

Applications for extrusion products

Sheets, bars and profiles

Used as components for industrial machinery and equipment, Promyde® polyamide 6 is the material of choice for leading producers in the extrusion of semi-finished products and solid bars for machining.

TANKS AND RESERVOIRS

Promyde PA6 blown extrusion grades with a viscosity of 5.0 provide improved mechanical properties and increased flow resistance in the molten state.

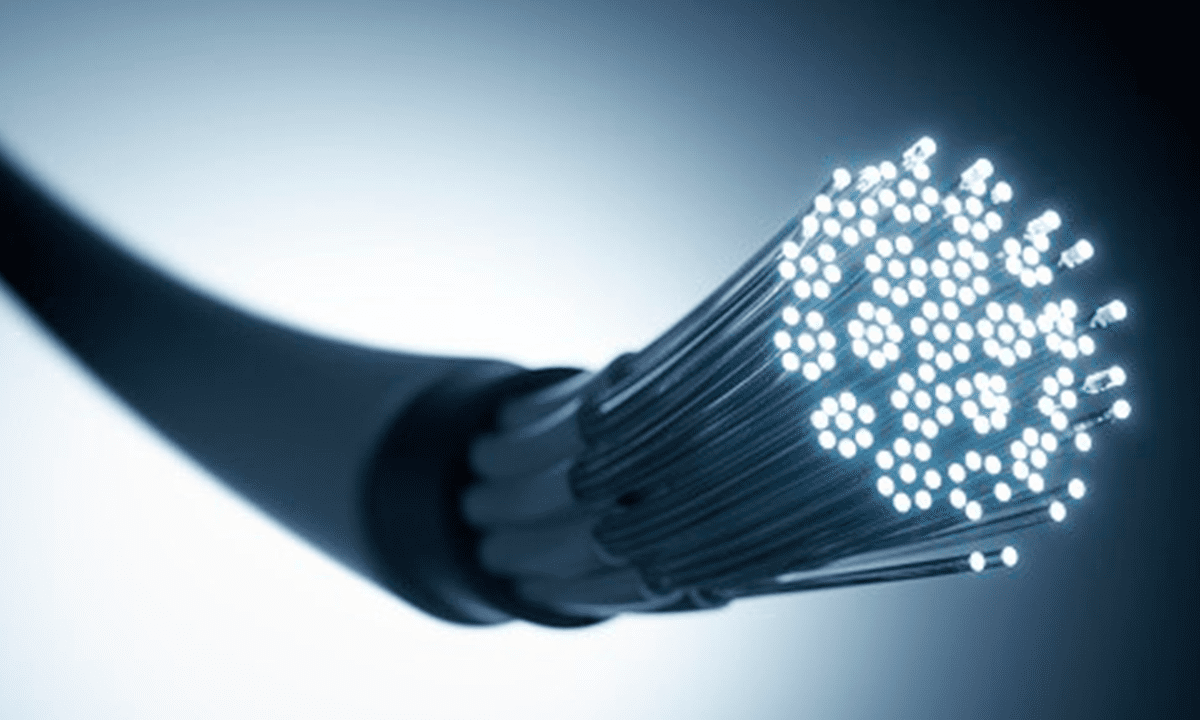

Optical fiber cable

Optical fiber cables are crucial in modern telecommunications. NUREL has developed a specific range of Proxylene (PBT) to reinforce and protect the delicate optical fibers within the cable. We also offer special grades of Promyde PA6 for optical fiber cables with high impact resistance requirements.

Cable jacketing

At NUREL, we provide heat-resistant, UV-stable and even flame-retardant polyamide and PBT compounds for the production of cables, wires and cable protection.

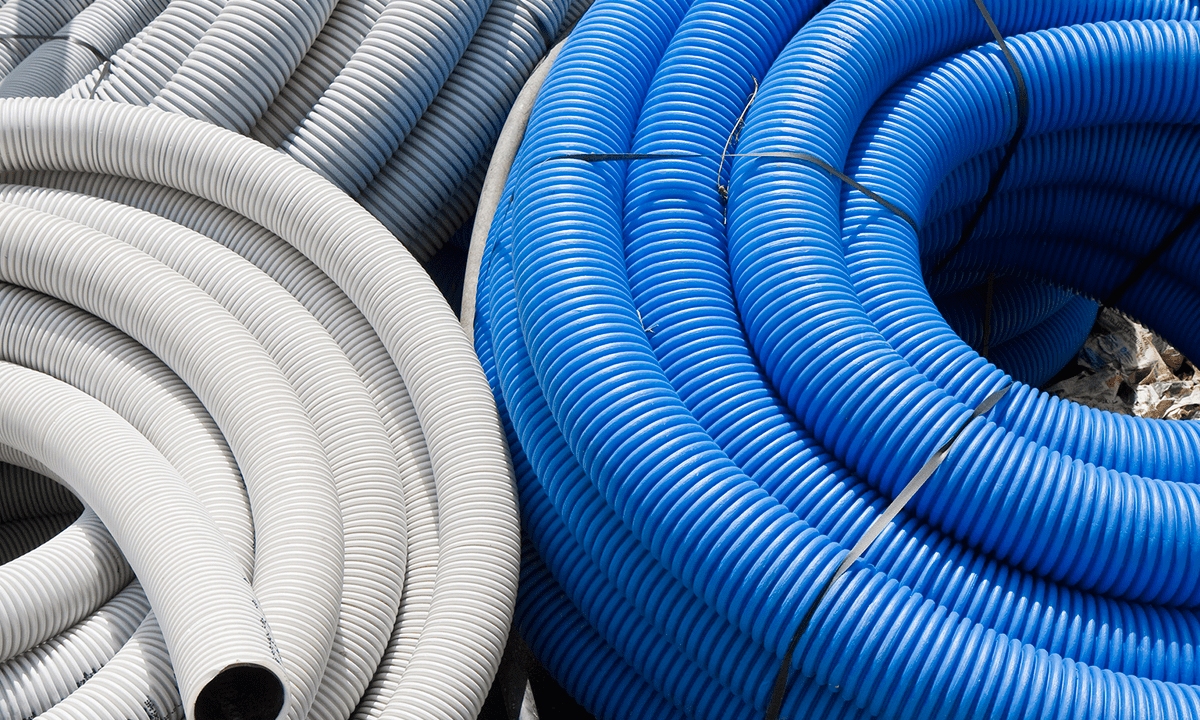

Corrugated pipes

Promyde B33 is commonly used for corrugated pipes of this diameter, and Promyde B36 and B38 for larger diameters.

Pipes and Tubes

Promyde® PA6 is widely used in pipe extrusion due to its exceptional strength, durability, and ability to withstand extreme temperatures, corrosion, pressure, and chemical resistance. Additionally, the Promyde PA range offers flexible grades specifically for this type of application.

Stand-up pouches

NUREL offers a complete range of Polyamide 6, Copolyamides and Ultra-High barrier materials for Doypacks. PA-based film materials not only help extend the shelf life of packaged food but also contribute to reducing plastic usage. Promyde polyamides offer excellent mechanical and barrier properties while providing an appealing packaging finish, thanks to their glossy appearance.

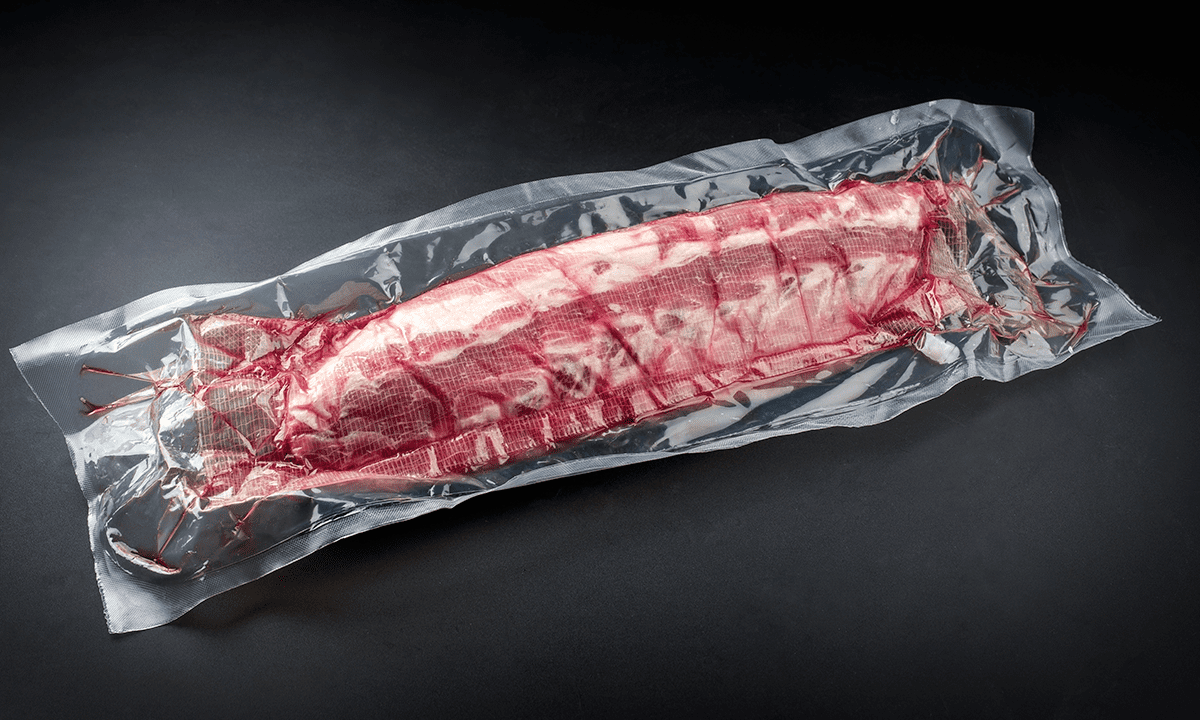

Vacuum Packaging

PA vacuum bags are commonly used to vacuum pack meats, fish, vegetables, cheese and prepared foods. Vacuum sealing helps to extend the shelf life of these products by preventing the growth of microorganisms that cause spoilage.

Deep thermoforming

NUREL offers a wide selection of polyamides and copolyamides designed for deep thermoforming packaging, with a focus on providing superior barrier properties and puncture resistance to effectively extend the shelf life of food products, thus contributing to the reduction of food waste. This type of packaging is particularly suitable for the preservation of large portions of fresh meat and whole cheeses.

Cheese packaging

Cheese packaging is essential to guarantee the quality, safety, and freshness of the product. It must meet a series of requirements to protect the cheese from oxidation, dehydration, and preserve its maturation process. NUREL offers solutions that adapt to these requirements by providing packaging with barrier properties and oxygen permeability.

Pasteurized and retort packaging

These containers are designed to withstand pasteurization and retorting processes, which are food preservation methods involving high temperatures and pressures, for which our latest generation copolyamides are the ideal material.

Oven bags

Promyde PA offers heat-resistant grades for films used in baking bags and oven-safe vacuum skin packs (VSP). These materials are perfect for cooking juicy and tender meat and vegetables, and have been validated for use in cooking food for up to 4 hours at temperatures up to 205°C.

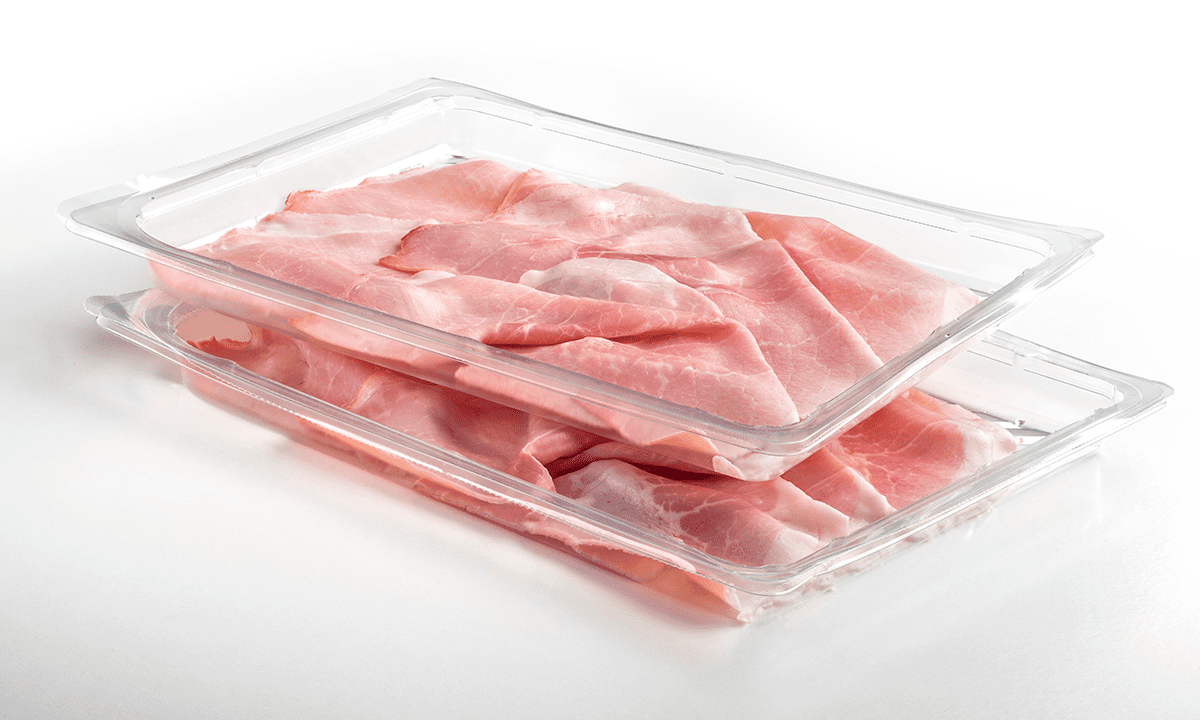

Lids and trays

NUREL offers a wide range of PA products to ensure performance in the most demanding MAP trays for food packaging. Optimal sealing, deep thermoforming, gloss and compliance with the most demanding barrier requirements are guaranteed.

Meat and bone-in meat packaging

Packaging for sharp-edged foods requires high puncture resistance, flexibility, moisture barrier, transparency, and an attractive gloss. NUREL offers a range of special copolyamides and polymers with high oxygen barrier properties for the manufacturing of vacuum bags and thermoformed packaging for meat.

Skin Packaging

Skin packaging is gaining popularity due to its lightweight and visually appealing design, as well as its superior technical performance. NUREL provides specially formulated copolyamides that exhibit exceptional strength, sealing capabilities, barrier properties, and unmatched glossiness.

Casing for sausages and sausage products

NUREL offers a specific range of Promyde PA 6 designed specifically for casing applications, as well as a new product range of ultra-high barrier polymers called Enoxite, to extend the shelf life of sausages and cooked meats

Fish and seafood packaging

For those fish and seafood packages that need specific characteristics, NUREL offers different alternatives in PA6 and Copolyamides that allow extending the shelf life of these foods.

Frozen food products

For frozen food products, co-polyamide materials and Enoxite ultra-high barrier polymers are the perfect choice. They are compatible with freezer storage and help prevent freezer burn in fish and meat.

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter