Biodegradable PA

Biodegradable PA6 : facing sustainable challenges

NUREL offers a specially designed solution for polyamide products disposed of in landfills at the end of their useful life: Promyde BIO. This new PA 6 polymer biodegrades at the end of its life, transforming into methane which, if properly captured, can be valorized as green energy. Promyde BIO, unlike oxodegradable solutions, can biodegrade in both aerobic and anaerobic media, without fragmenting under oxygen or UV rays.

NUREL does not support littering of any kind, but, in case of an inappropriate disposal of the plastic waste, Promyde BIO would also biodegrade in soil. Then, Promyde BIO could be also a good option in applications when structural parts could end up on the environment unintentionally. Then, aerobic biodegradation will take place avoiding pollution of soil.

Promyde BIO Applications

Standard PA6 is used for its mechanical properties and often cannot be substituted by other materials. PA-based materials do not enter the recycling channel, ending up in landfills where biodegradation is not possible. PROMYDE® BIO is the sustainable solution to this problem, as it promotes the biodegradation of PA-based elements.

Thus, biodegradable polyamides 6 are recommended for:

- Applications where PA is required.

- Multi-material applications such as complex packaging or over-injected parts.

- Injected parts for e.g. electric cars and household appliances.

Promyde Bio and carbon footprint

The final disposal/waste system plays an important role in the carbon footprint of any material.

The impact of the carbon footprint must be analyzed according to each disposal scenario.

The main environmental impact of Promyde BIO is related to its landfill management, where the resulting methane is captured and converted into energy, resulting in a carbon footprint reduction of up to 15%.

Click here to resolve your doubts with our detailed Q&A on biodegradable polyamides

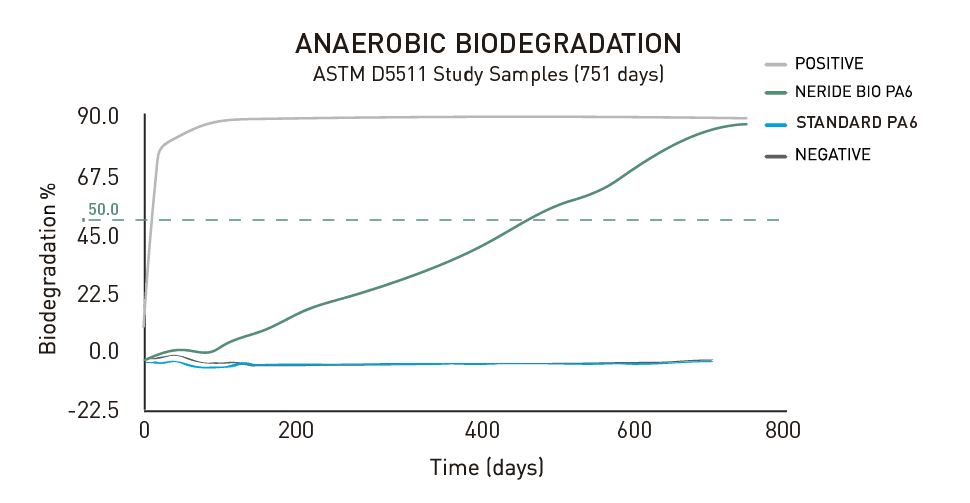

Anaerobic biodegradation

Anaerobic biodegradability according to ASTM D5511. After 751 days: Up to 84.2% biodegradation

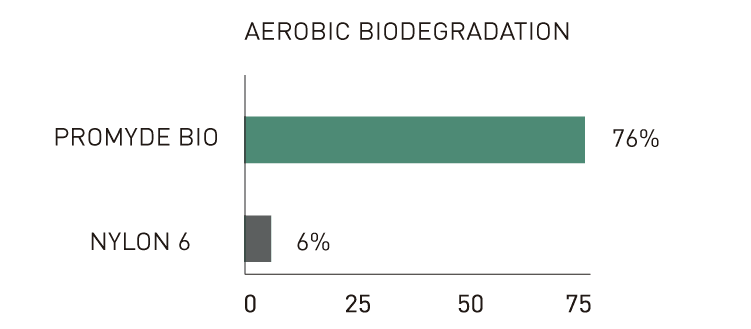

Aerobic biodegradation

NUREL does not support the dumping of waste of any kind. In case of improper disposal of plastic waste, PROMYDE® BIO also biodegrades in the soil.

Thus, aerobic biodegradation is the degradation of organic matter by microorganisms in oxygen environments, such as soil.

Aerobic certification, according to ISO 17556:2012, establishes 76% biodegradation after 90 days in active soil.

Download our catalogues

Promyde Bio

Other sustainable polyamide solutions

Recycled

Recyclable

Biobased and Biocircular

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter