RESISTANCE AND EFFICIENCY IN BUILDING CONSTRUCTION

Modern construction has undergone a significant transformation thanks to engineering plastics, especially PA and PBT, which have become essential materials. Their durability, resistance to corrosion, tolerance to extreme conditions, and low maintenance make them economically appealing and efficient. In the construction sector, where environmentally friendly products meeting rigorous strength standards are required, NUREL offers solutions that replace metal components, enhance insulation, and reduce environmental impact.

PROMYDE® POLYAMIDE AS THERMAL INSULATION AND METAL REPLACEMENT IN STRUCTURAL ELEMENTS

Promyde PA6 compounds are highly regarded in the construction industry due to their outstanding mechanical, chemical, and thermal properties. They are used in structural elements, insulation systems, and more, contributing to sustainable and efficient construction. Common uses of polyamide 6 in construction include thermal insulation in roofs, closures for windows and doors, corrosion-resistant pipes, durable screws and fasteners, lighting components, connectors, and electrical switches.

PROXYLENE® PBT ELECTRICAL INSULATION IN BUILDINGS

On the other hand, Proxylene PBT is employed in insulation applications for electrical components such as junction boxes and housings, thanks to its good electrical resistance, dielectric insulation, heat resistance, weather resistance, and dimensional stability. It is crucial to consider the specific requirements of each project when selecting the appropriate material for construction applications, including temperature resistance, chemical resistance, fire resistance, and dimensional stability.

Solutions

Reinforced solutions

Our mineral filler, glass fiber and carbon fiber reinforced solutions achieve the best performance for injection molding and extrusion applications.

High Viscosity

NUREL offers high viscosity grades in both polyamide for extrusion blow molding and extrusion processes and PBT for extrusion, pipe, cable and profile applications.

Hydrolysis resistant

NUREL provides PA6 and PBT grades with high hydrolysis resistance, specifically developed to withstand exposure to moisture, coolants, fuels, oils and chemicals, even in harsh environments and elevated temperatures.

Surface Finish

Our range of reinforced PA6 grades, is designed to deliver a superior surface finish while maintaining high mechanical performance. It is ideal for visible or aesthetic components. Additionally, our PP compounds include talc-reinforced grades and scratch-resistant options, suitable for technical applications where appearance also matters.

High flow

Our High Flow types deliver outstanding mechanical performance and greater production efficiency. They are especially recommended for parts with complex geometries and to improved surface finish quality.

High Thermal stabilization

We offer PA6 and PA66 grades with advanced thermal stabilization up to 180 °C, also available in metal- and halogen-free formulations.

UV Resistance

To increase the lifetime of parts exposed to sunlight, we offer compounds with UV resistant properties.

Applications

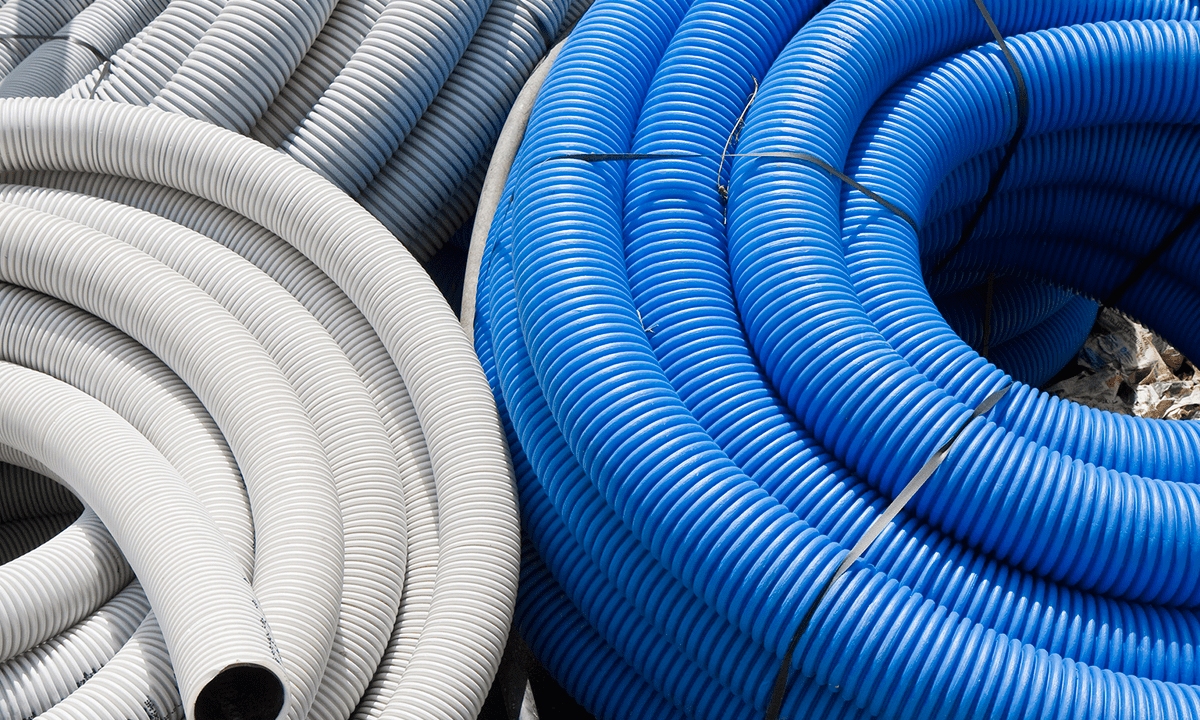

Corrugated pipes

Promyde B33 is commonly used for corrugated pipes of this diameter, and Promyde B36 and B38 for larger diameters.

Pipes and Tubes

Promyde® PA6 is widely used in pipe extrusion due to its exceptional strength, durability, and ability to withstand extreme temperatures, corrosion, pressure, and chemical resistance. Additionally, the Promyde PA range offers flexible grades specifically for this type of application.

Wheels

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec viverra aliquet placerat. Vestibulum tincidunt nisl nisl, eu bibendum augue dictum sed.

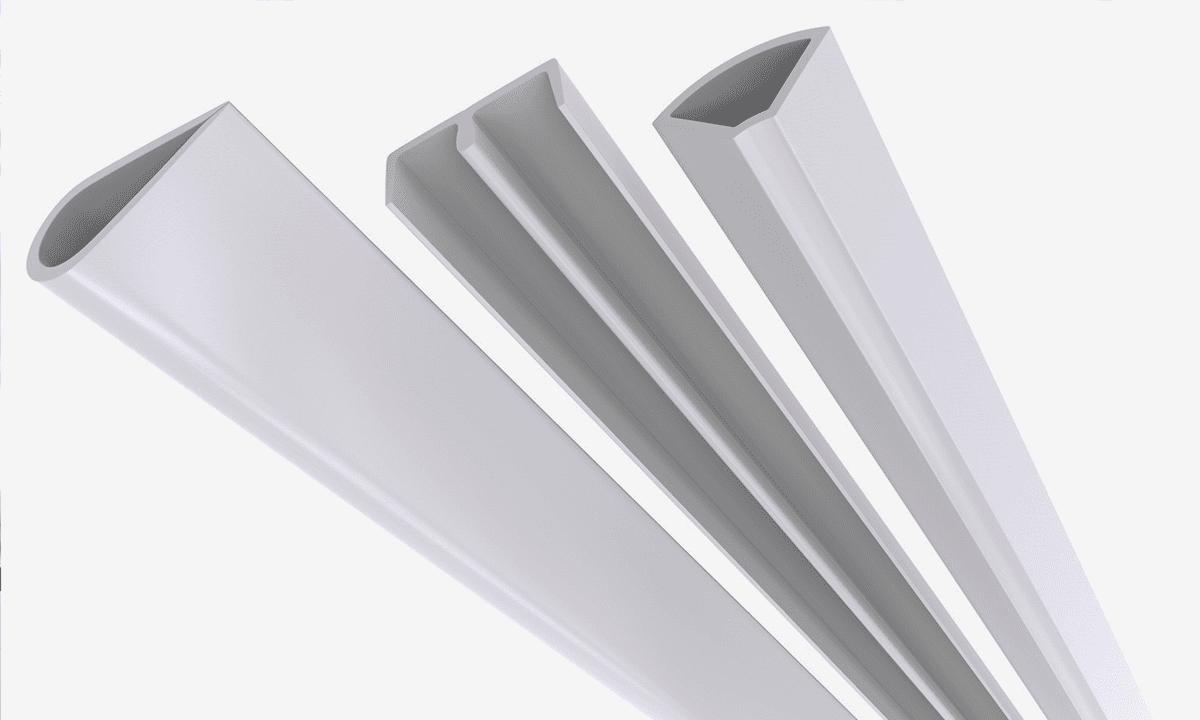

Sheets, bars and profiles

Used as components for industrial machinery and equipment, Promyde® polyamide 6 is the material of choice for leading producers in the extrusion of semi-finished products and solid bars for machining.

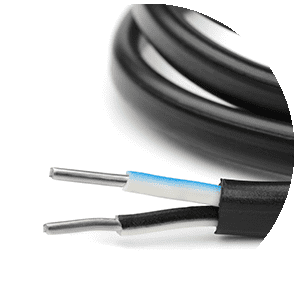

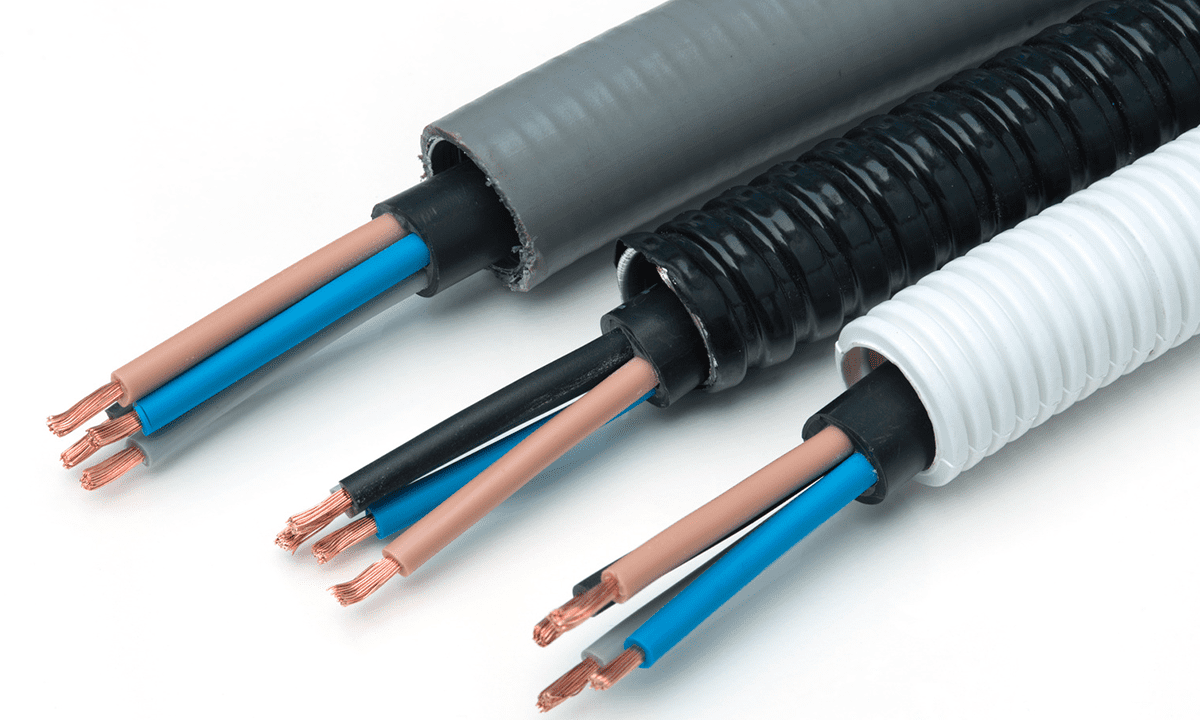

Cable jacketing

At NUREL, we provide heat-resistant, UV-stable and even flame-retardant polyamide and PBT compounds for the production of cables, wires and cable protection.

RELATED MARKETS

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter