50 YEARS OF EXPERIENCE IN POLYMER PRODUCTION

NUREL ENGINEERING POLYMERS, a Spanish company, is part of the SAMCA Group and has more than 50 years of experience in polymerization of polyamide and development of engineering plastics.

NUREL started its polyamide production in 1968. Since its acquisition in 1999 by the SAMCA Group, there have been continuous investments in technology and an increase in production capacity that have strengthened NUREL‘s presence as a producer of engineering thermoplastics.

SAMCA‘s corporate policy is based on constantly supporting the group’s research and development activity, together with a constant reinvestment of profits in the acquisition of state-of-the-art technologies.

Over the years, NUREL has acquired a wide knowledge in polymer chemistry and has put all this learning at the service of its customers, by developing polymers for any type of application, either by extrusion or injection.

INNOVATION AND EXCELLENCE DEFINE US AS A COMPANY

Innovation is a priority for NUREL Our R&D&I team concentrates its efforts on the development of new products by modifying the polymeric chain and the correct choice of additive packages, in order to meet the requirements of the most demanding injection and extrusion applications.

Our main objective is to guarantee high quality products with stable properties and sustainable production. For this purpose, we use our state-of-the-art technology and polymerization know-how, striving for excellence from the procurement of our raw materials to the packaging of our polymers.

In line with our commitment to Quality and Sustainability, our plant is evaluated year after year under the ISO 9.001, ISO 50.001 and ISO 14.001 criteria.

INTEGRATION AND INVESTMENT ARE THE KEYS TO OUR SUSTAINABLE DEVELOPMENT

We believe that sustainability must be based on the excellence and control of all our processes. At NUREL we are committed to vertical integration as the key to reducing our environmental impact, thus reducing intermediate displacements, reducing the generated waste and taking advantage of the energy resources that we, ourselves, generate.

In recent years, we have worked to enhance our vertical integration:

- MANUFACTURING OF POLYMER COMPOUNDS: Acquiring new compounding lines at our premises enable us to reduce intermediate displacements and therefore our carbon footprint.

- POLYMER RECYCLING: This new investment allows us to reuse the discarded nylon bobbins in our spinning and convert them into recycled compounds for injection moulding applications.

- 100% SUSTAINABLE ENERGY: 22,000 solar panels have been installed for self-sufficiency.

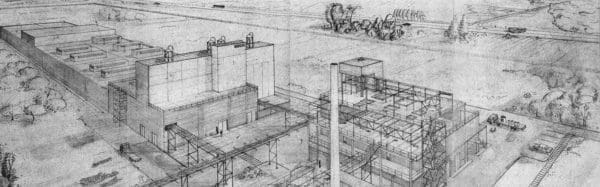

The American multinational petrochemical company ESSO is developing the engineering project for the construction of a nylon production plant in the Santa Isabel district of Zaragoza.

The polymerization plant (P1) with four lines, the spinning plant (H1) with various sections, offices and service facilities were built and upgraded.

On December 10, production begins at the plant with 550 employees. The following year, the official inauguration takes place, attended by the Ministers of Industry and Development Plan.

The ESSO Fibers' nylon fabrics began to be advertised by means of model shows throughout Spain and by attending trade fairs. The trademark of the nylon fibers is NUREL.

The plant is taken over by Banco Industrial del Mediterráneo and subsequently by the English company Imperial Chemical Industries. It is renamed after the brand name, NUREL, and the development of a new polyester production plant begins.

On January 25, the polyester yarn plant is inaugurated with the Minister of Industry. Daily production of 75 tons starts, under the polyester fiber brand name: PROXYLENE.

At the end of the decade, a caprolactam recovery and industrial waste depolymerization plant is started up for recycling. NUREL reaches its historical maximum number of employees, 1503.

NUREL has its own logistics network, distribution warehouses and a central office in Barcelona where some of the most important departments are located.

A cogeneration plant is inaugurated, which converts primary energy into electrical energy and heat until 2005. The company starts working with PCs and an IBM-AS-400 management system with several terminals.

NUREL obtains ISO 9001 certification for quality management and assurance. A year later, the management team acquires the plant in view of ICI's intention to close it.

Production is changed from LOY to POY, the first warping unit is installed and new developments in polymerization begin. The multifilament yarn brand NOVAREL is launched.

The Aragonese business group SAMCA purchases the NUREL production plant from the previous owner. In the summer of 1999 the first website in the history of NUREL is launched.

NUREL achieves ISO 14001 Environmental Management certification, which certifies the identification of environmental risks and the application of prevention procedures to avoid environmental accidents.

A new polyamide polymerization plant (P2), a new spinning plant (H2) and a mechanical recycling unit are commissioned. Production of microfibers begins.

NUREL's plastics division is created since, up to that moment, all the polymer produced in the plant was used for self-supply. The following year the commercial brand is launched.

The first patent is published regarding the encapsulation technology used by NUREL, being the only company in the sector to produce cosmetic fibers. NUREL launches the range of cosmetotextiles with NOVAREL Aloe.

Plant modifications are made in order to produce new high viscosity recipes suitable for film, allowing NUREL to enter this market. The production of nylon 66 yarn in spinning begins.

In January, a modern H3 nylon spinning plant was inaugurated to replace the original 1968 plant (H1). A year later, the plastics division is relaunched with a new brand name: PROMYDE.

A Solid State Postcondensation unit is installed to produce high viscosity polyamide on a large scale, consolidating NUREL in the packaging and semi-finished products market.

Opting for a more sustainable industrial development, the business is expanded with the start-up of a new biopolymer plant, INZEA. NUREL obtains ISO 50001 certification and the cosmetics sub-company ZEOMETIC is created.

A new extrusion unit was installed to manufacture polyamide compounds and the re-grinding line was renewed to recover industrial waste and convert it into pellets suitable for production.

NUREL is 50 years old with 350 employees and produces 16,000 tons per year of compounds, 27,000 tons per year of polyamide polymer, 2,000 tons per year of recycled polymer and 7,200 tons per year of nylon continuous yarn.

NUREL develops and introduces a new range of PBT and PET based compounds , under the brand name Proxylene, expanding our markets in the automotive and electrical sectors.

In line with the company's commitment to the environment, 22,568 solar panels are installed on the floor and roofs of the NUREL industrial area, making it one of the largest self-consumption facilities in Europe with no discharge to the grid. Given the growing demand for more sustainable plastics, a second INZEA is launched.

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter