Reinforced polyamide for high quality finish applications

In some applications, the appearance and finish of the injected parts are of vital importance. For cases where a special surface finish is required, along with the need for reinforcement to meet high-performance standards, Promyde® offers a range of “S” grades in both PA6 and PA66. These grades are specially formulated to achieve a smoother and more uniform surface finish compared to conventional glass fiber-reinforced grades.

Ways to Improve the Surface Finish of a Part

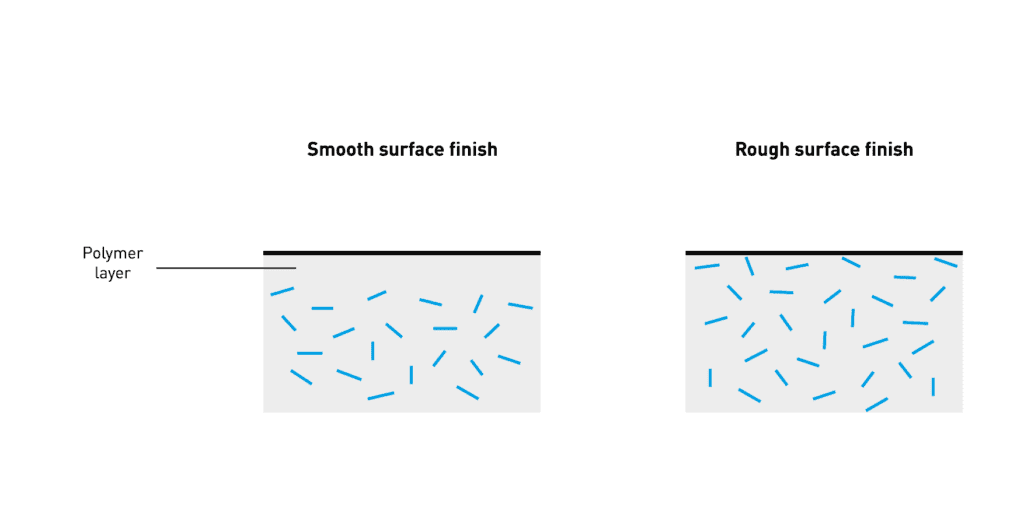

Due to their length, glass fibers commonly used as reinforcement tend to orient in the flow direction during the injection process and can surface, resulting in a poor finish of the part.

Additionally, the significant differences in shrinkage between PA6 and glass fiber can lead to rough surfaces. The glass fiber hinders the contraction of the polyamide, especially in the longitudinal direction of the fiber, resulting in an uneven surface.

Promyde “S” line of PA6 and PA66 compounds feature improved flowability and fibers with specially designed geometry to prevent these undesired phenomena and enhance the part’s finish. By injecting high-flow reinforced polymers, the formation of a thin polymer layer on the surface of the parts is promoted, preventing glass fiber accumulation in this area and achieving a more homogeneous finish.

High-Flow PA Grades and Special Reinforcements

Thanks to their high flowability, our Promyde High Flow grades allow for the production of injection-molded parts with a good surface finish, especially when using high-reinforcement content grades. The high flowability of the base polymer aids in the dispersion of glass fiber during injection. The polyamide enters the mold cavity first, filling the surface of the final part. Then, the glass fiber fills the internal volume, preventing the surfacing of glass fiber on the surface.

Using the appropriate injection parameters will also help achieve the best possible surface finish: increasing the melt and mold temperature, injection speed, and increasing the holding pressure, all contribute to obtaining a better surface quality.

High-Flow PA Grades and Special Reinforcements

Thanks to their high flowability, our Promyde High Flow grades allow for the production of injection-molded parts with a good surface finish, especially when using high-reinforcement content grades. The high flowability of the base polymer aids in the dispersion of glass fiber during injection. The polyamide enters the mold cavity first, filling the surface of the final part. Then, the glass fiber fills the internal volume, preventing the surfacing of glass fiber on the surface.

Using the appropriate injection parameters will also help achieve the best possible surface finish: increasing the melt and mold temperature, injection speed, and increasing the holding pressure, all contribute to obtaining a better surface quality.

Applications

Kitchen utensils

Kitchen utensils made from reinforced PA and PBT are an alternative to metal due to their characteristics of strength, durability, and lightweight. These polymers are reinforced with materials such as fiber and glass beads to enhance their mechanical properties and scratch resistance.

Front-end modules

For vehicle front-end parts, Promyde's polyamide composites can reduce closing force by 30%, improving the properties of the manufactured applications, reducing production costs.

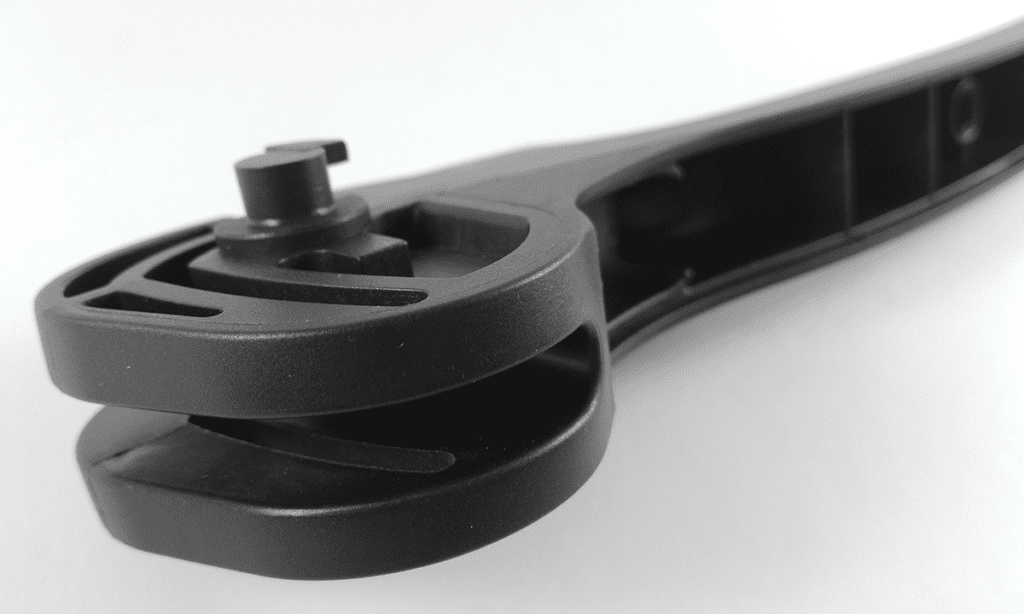

Handles, knobs, and levers

Handles, knobs, and levers found in kitchen utensils, furniture, appliances, and other products rely on the properties of reinforced PA and PBT with fiberglass for their increased tensile and impact strength, durability, lightweight nature, and heat resistance.

ELECTRIC TOOLS

Reinforced grades of Promyde PA6 are used in the manufacturing of casings for professional-grade electric tools. These tools need to be lightweight while maintaining high impact resistance, temperature resistance, and dimensional stability, as they are used in both indoor and outdoor environments where efficiency is crucial.

RELATED MARKETS

MOBILITY AND AUTOMOTIVE

The mobility sector has always been a leader in mechanical innovation and process optimization. At NUREL, we support this evolution with our range of engineering polymers - PA6, PA66, PBT, PET and PP - designed to respond to the industry's demand for lighter, more sustainable and efficient solutions.

Electrical and electronic

NUREL PA, PBT, PET, PBT/PET and PP compounds are present in parts and components of electrical and household appliances. Parts molded with Promyde®, Proxylene®, Olexene®, or Recomyde® can be found in food processors, white goods such as refrigerators, washing machines and dryers.

Consumer goods

Engineering plastics are used in a multitude of applications that reach the end consumer. Household appliances, tools, electronic devices, sports equipment and kitchen utensils all feature materials made of NUREL polyamide and PBT compounds.

OTHERS SOLUTIONS

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter