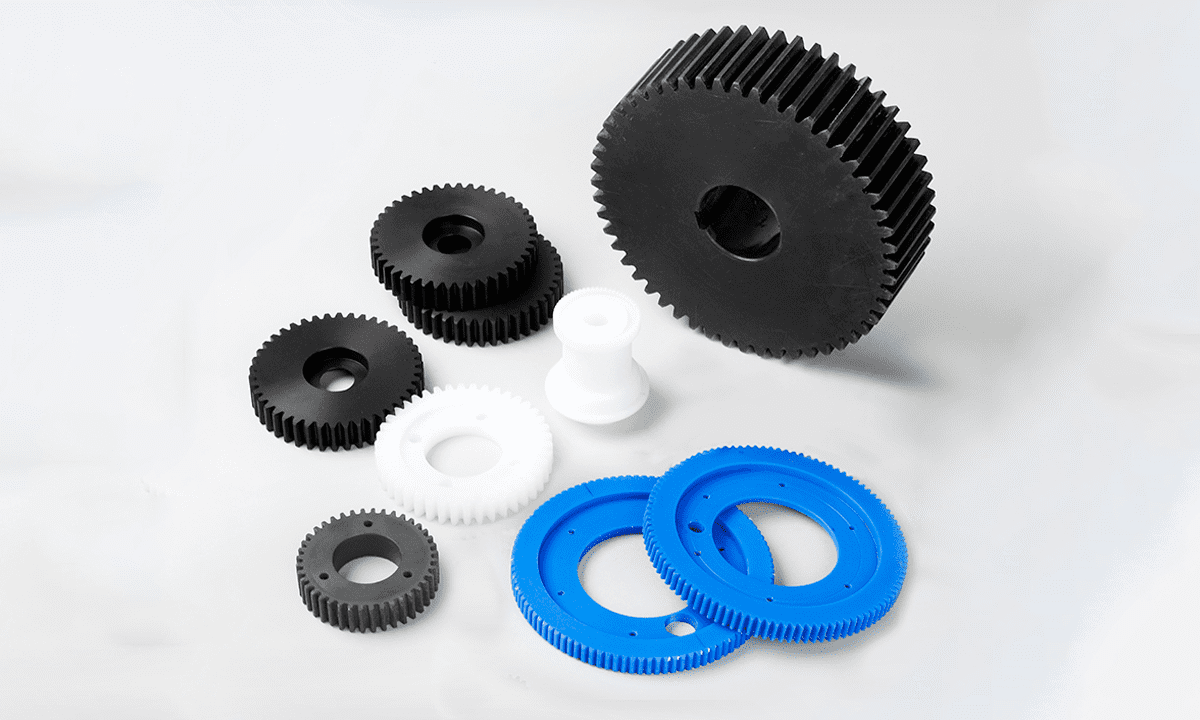

PA AND PBT IN GEAR AND BEARING MANUFACTURING

PA and PBT are commonly utilized in gear and bearing manufacturing due to their mechanical attributes. Both are lightweight materials, which can be advantageous in applications where reducing the total system weight is desired. These parts can be produced either through injection molding or by machining from solid bars, allowing for flexibility in the manufacturing process.

Choosing Between PBT and PA

The choice between PBT and PA, specifically Proxylene PBT and Promyde PA, for gear and bearing applications depends on the specific requirements of the application. PBT is often preferred for its low friction and dimensional stability, making it suitable for precise motion transmission and minimal wear. On the other hand, PA’s excellent wear resistance, self-lubricating properties, and shock absorption make it a good choice for applications that require durability and reduced maintenance.

Tailor-Made Polymers for Specific Requirements

Certain machinery parts, such as those used in the food industry, necessitate specific polymer developments, including properties like magnetic detectability or food contact approval. Promyde PA6 offers a broad portfolio of PA compounds to meet these diverse requirements.

MARKETS

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter