BIOPLOLYMERS BARRIER SOLUTIONS

INZEA OFFERS SOLUTIONS WITH A HIGH OXYGEN BARRIER

INZEA® has a solution to achieve 100% biodegradable, compostable and high oxygen barrier packaging for the correct preservation of foodstuffs. INZEA barrier grades can be tailored to customer requirements for efficient and sustainable food preservation packaging.

INZEA Biopolymers Barrier Solutions Specifications

INZEA biopolymers grades with barrier properties are food contact certified, have good weldability and good mechanical properties, suitable for printing, laminating and automatic packaging. INZEA also offers transparent grades for the design of these barrier structures.

In addition, our R&D&I department is strongly committed to sustainable packaging, developing new biopolymers barrier products, such as water-soluble barrier grades, to be processed in monolayer for both extrusion and injection moulding.

100% COMPOSTABLE multi-layer PACKAGING

One of the main problems of conventional multilayer packaging is its management as waste. Avoiding multi-layers is not always possible as technical requirements must be met to ensure the preservation of the food. Therefore, the solution is to find a 100% compostable alternative that can be managed together with the food waste.

INZEA biopolymers provides blown film and thermoformed cast film grades that in co-extrusion processes give a biodegradable alternative that minimizes food waste, guaranteeing food preservation and minimizing plastic waste, since they can be composted together with organic waste.

INZEA’s biopolymers barrier solutions are designed to be manufactured in 2 to 5-layer coextrusions and with a viscosity suitable for blown film extrusions.

WHAT IS INZEA

The world is changing and the plastics industry has to adapt to a new situation where sustainability is a priority for governments, businesses and consumers. INZEA® is our response to our customers’ demand for more sustainable plastic materials.

INZEA is a range of biopolymers which can replace traditional plastics in different applications such as bags, mono-use items and packaging, with the advantage of being biodegradable and compostable.

INZEA product range is obtained from renewable sources and is designed to return to nature by different disposal methods like industrial & home composting, or by biodegradation in different environments.

APLICATIONS

Trays

INZEA® offers biodegradable and compostable solutions for food contact trays for take away and cooked product packaging. Thermoformed trays, film-coated cellulose trays, paper-like and laminated trays can now be managed together with organic waste.

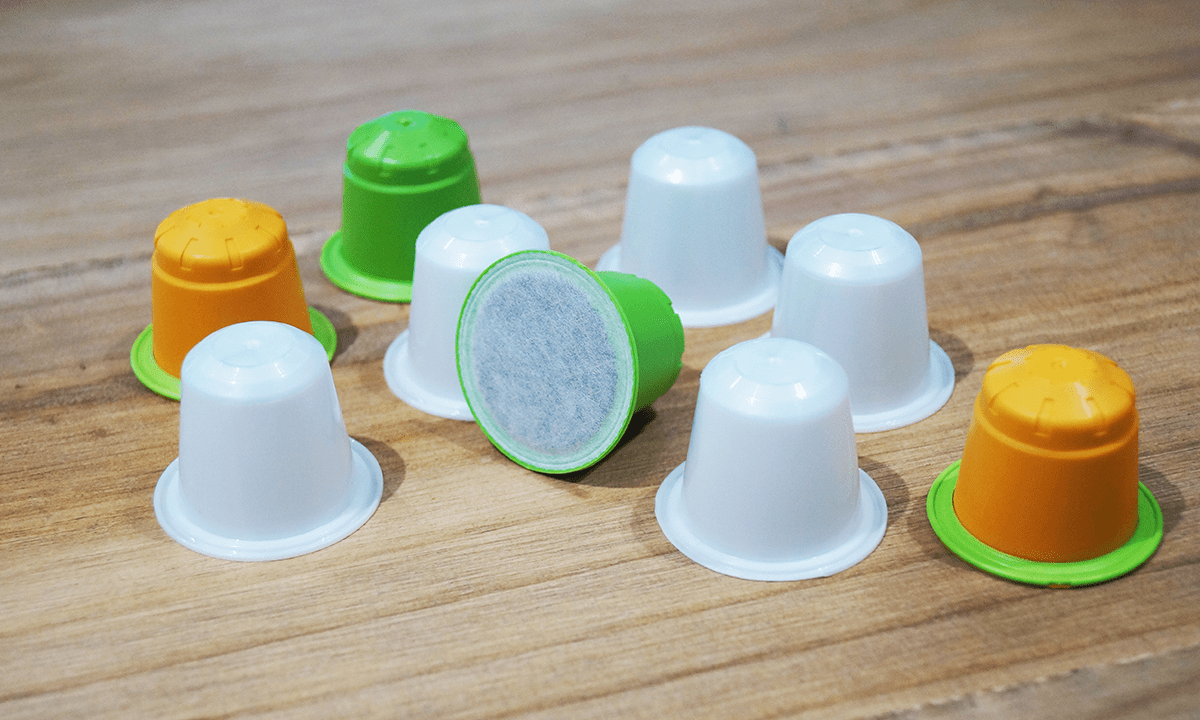

Coffee capsules

INZEA ® has grades suitable for the manufacture of coffee capsules that meet the required mechanical, thermal resistance and barrier requirements.

Stand-up pouches

Soluciones INZEA para stand up pouches y envases alimentarios biodegradables y compostables, alternativa sostenible a envases multimateriales no reciclables.

Flexible packaging for liquids

INZEA® offers biodegradable and compostable solutions for flexible packaging of liquids such as milk pouches and sauces.

Flow pack

INZEA® flow packs offer biodegradable and compostable solutions specifically for fresh food packaging.

Bottles

INZEA® has suitable grades for the production of compostable bottles by both injection and extrusion blow moulding, without varying the manufacturing parameters.

Freezer bags

Frozen bags made of INZEA® compostable biopolymers maintain, after 124 days at -30°C, the same modulus and tear strength.

RELATED MARKETS

Food Market

INZEA® offers a wide range of compostable biopolymers for food packaging that can be processed on conventional blown film extrusion and flat sheet extrusion lines.

OTHERS SOLUTIONS

Want to stay updated on the latest on NUREL Biopolymers?

Subscribe to the Newsletter