New advanced barrier materials

NUREL has been actively involved in the development of an innovative line of advanced barrier materials, Enoxite®, engineered to simultaneously enhance product shelf life and minimize the environmental impact associated with conventional multilayer barrier materials.

What is ENOXITE®?

Enoxite® represents an innovative portfolio of barrier polymers developed by NUREL for use in both rigid and flexible packaging This range encompasses ultra-high oxygen barrier materials, recyclable barrier grades, compostable barrier solutions and water-soluble alternatives. Enoxite polymers can be processed using conventional equipment for blown, cast and thermoforming film production. These Enoxite types can be used as an internal barrier layer in multilayer structures, combined with PE, PP, PET, PS, PA and compostable biopolymers.

Key properties of enoxite barrier polymers

The Enoxite® product range is built upon two fundamental benefits:

- Enhanced Barrier Performance: Enoxite’s innovative solutions provide an exceptionally effective barrier against moisture and oxygen, significantly prolonging product shelf life. This contribution is pivotal in reducing food waste and ensuring product quality.

- Minimized Environmental Impact: Enoxite can help to achieving multiple sustainability objectives, including the reduction of plastic content in packaging, the improvement of recyclability in multilayer barrier films, and the facilitation of compostability of barrier packaging solutions.

Enoxite advances barrier materials range

Enoxite: the alternative to EVOH

Enoxite E10 is an ultra-high barrier polymer that can be an alternative to EVOH in barrier structures. Enoxite offers superior oxygen transmission rate (OTR) values, a similar manufacturing process, and the added advantage of water solubility.

- Ultra-high barrier: with OTR values surpassing EVOH, Enoxite E10 helps preserve the freshness and quality of packaged products during extended storage periods. Its remarkable barrier properties enable the production of lighter packaging and significantly extend the shelf life of food, consequently reducing food waste and minimizing environmental impact.

- Heat Treatment: Enoxite E10 and E30 are suitable for pasteurization applications up to 90°C/1 hour.

- Effective Grease Resistance: Enoxite also exhibits impressive resistance to grease and provides essential protection for the aroma and flavor of packaged products. This ensures the safety of the packaged items while maintaining their sensory attributes and preventing cross-contamination.

- Food Contact Compliance: Enoxite types in the middle layer can be used for contact with food depending on the specific type of food, duration, and conditions, in accordance with European directive N°10/2011.

- Transparency Advantage: Enoxite range are transparent grades, making it suitable for combination in multilayer structures with PET, PE, and PA.

- Exclusive Enoxite E30: The newly introduced Enoxite E30 offers as stable barrier levels under various humidity conditions and it does not require a tie layer.

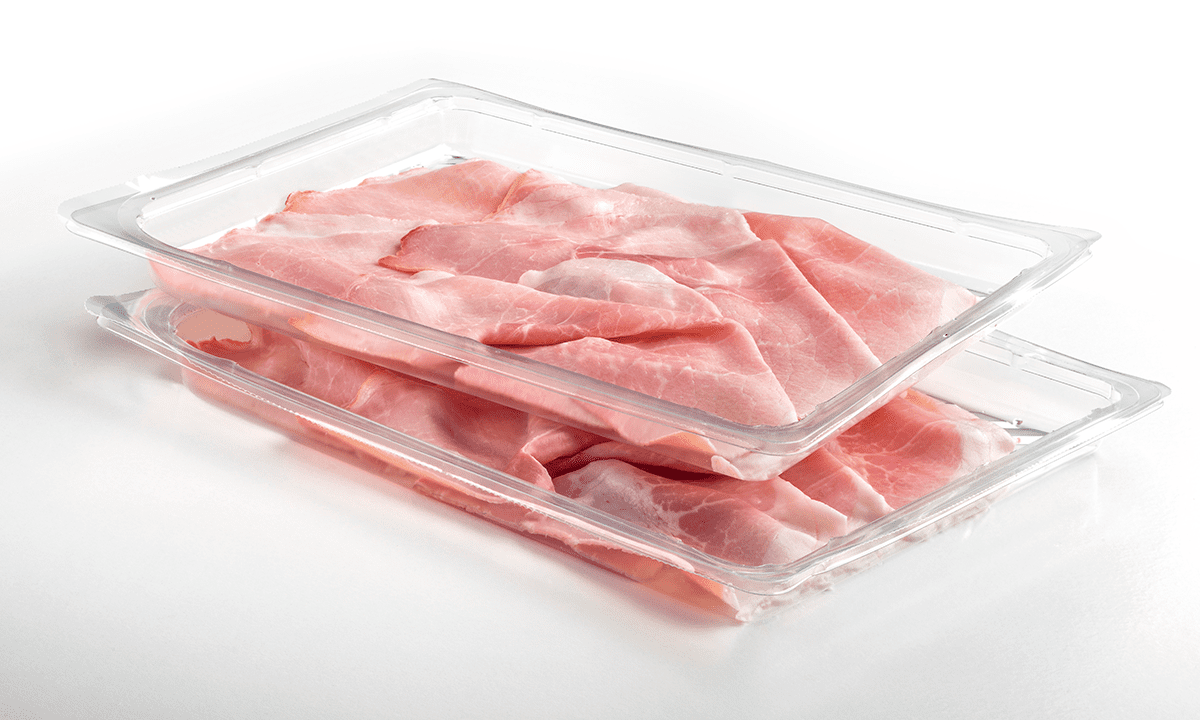

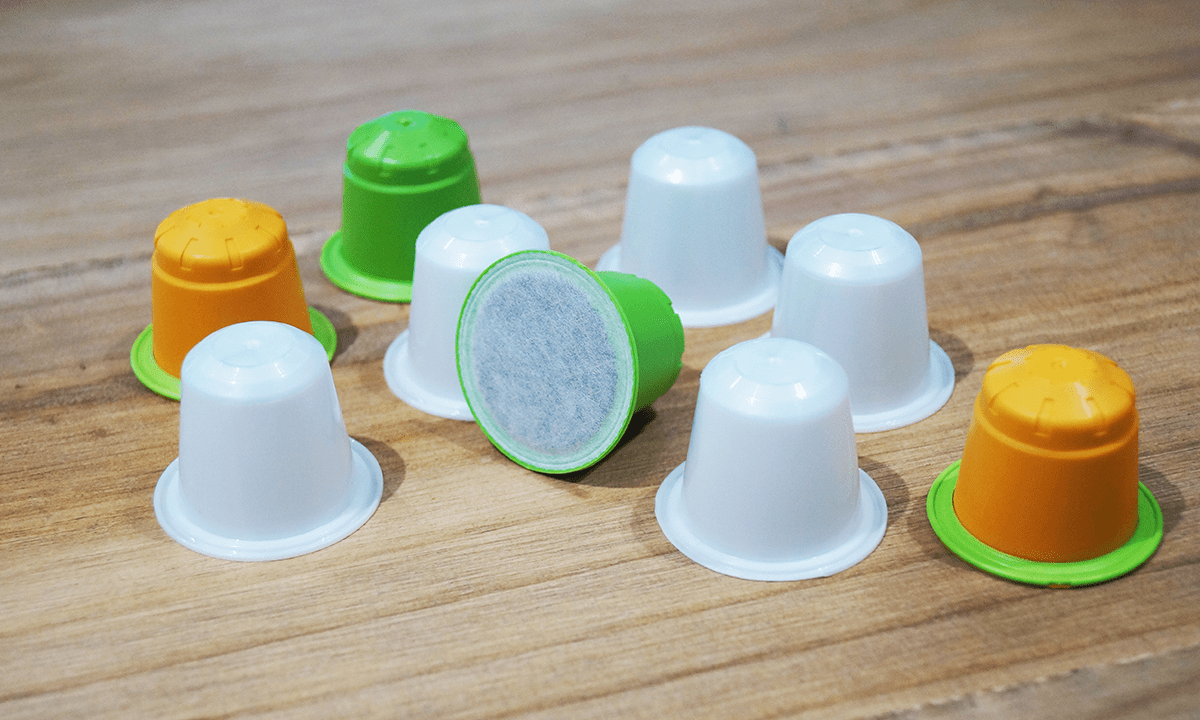

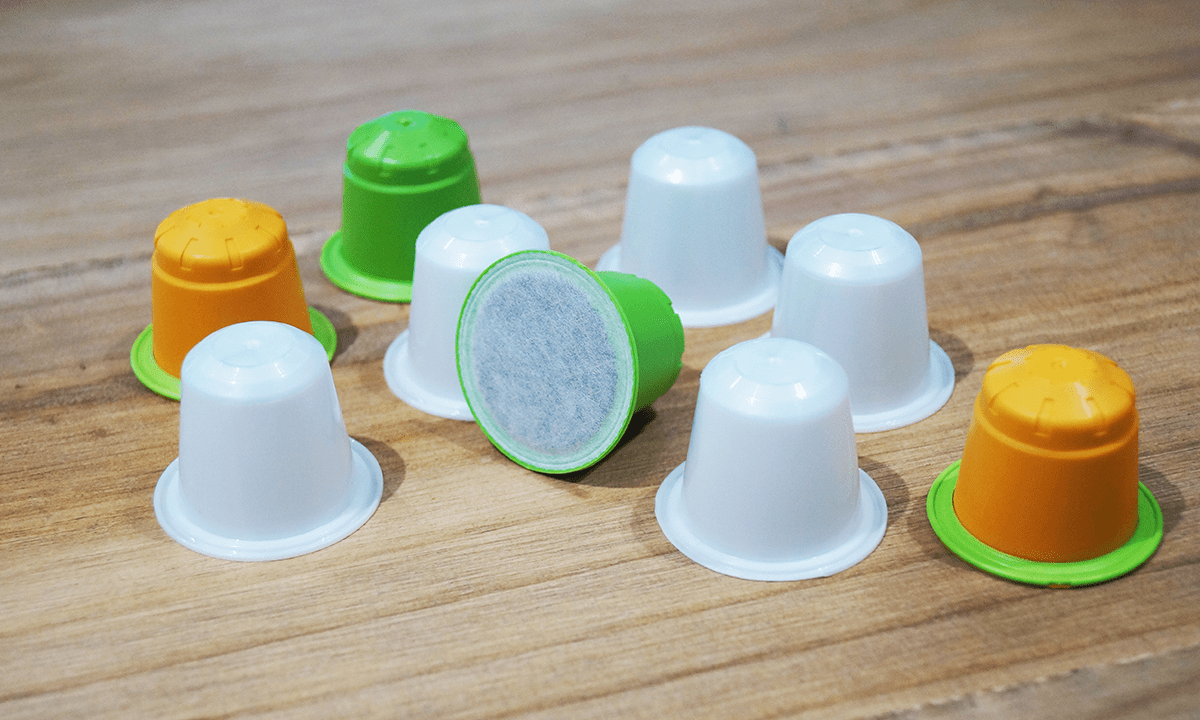

Enoxite® Ultra-high Barrier applications

Enoxite® is used for packaging foods that require a high barrier to oxygen and gases, such as bags for packaging fresh foods like meat, fish and cheese; trays for prepared foods, packaging of dairy products and packaging of powdered products like coffee and nuts, which are very sensitive to oxidation.

Water solubility to facilitate recycling at different temperatures

Another notable feature of these ultra-high barrier polymers is their water solubility. This solubility enhances the recyclability of multilayer flexible barrier packaging, making it the right choice for the production of multi-material packaging.

- Enoxite E10: In multilayer film structures, Enoxite E10 dissolves when exposed at temperatures above 50ºC during the washing stage at recycling facilities. These facilities employ high-temperature water tanks for cleaning waste materials before recycling. This process produces high-quality recycled polymers that can be employed in the manufacturing of new high-value-added products.

- Enoxite E20: can be dissolved in cold water, facilitating the multilayer film separation at any recycling facility.

Barrier materials for compostable miltilayer films

Compostable packaging plays a vital role in reducing the environmental impact associated with plastic packaging. Combining the sustainability benefits of compostability with the shelf-life extension advantages offered by barrier packaging, we have developed Enoxite E20 and E30.

- Enoxite E20 is a high barrier polymer that provides a viable oxygen barrier compostable packaging structures. It meets the compostability criteria outlined in EN 13432 and can be dissolved in cold water.

- Enoxite E30 has an excellent barrier to oxygen and water vapor. Its oxygen barrier doesn’t change with ambient humidity. It is suitable for blown and cast film extrusion, with the advantage of avoiding the use of tie layer. Corona treatment is not required.

Barrier materials for compostable miltilayer films

Compostable packaging plays a vital role in reducing the environmental impact associated with plastic packaging. Combining the sustainability benefits of compostability with the shelf-life extension advantages offered by barrier packaging, we have developed Enoxite E20 and E30.

- Enoxite E20 is a high barrier polymer that provides a viable oxygen barrier compostable packaging structures. It meets the compostability criteria outlined in EN 13432 and can be dissolved in cold water.

- Enoxite E30 has an excellent barrier to oxygen and water vapor. Its oxygen barrier doesn’t change with ambient humidity. It is suitable for blown and cast film extrusion, with the advantage of avoiding the use of tie layer. Corona treatment is not required.

Download our catalogues

Enoxite

Related solutions

Barrier solutions

We offer innovative solutions in PA, copolyamides, and barrier materials for food packaging, developed to enhance oxygen barrier properties and extend shelf life.

Sealing films

Polyamides and copolyamides specially developed for films, lids, thermoformed trays, and vacuum bags. We offer low-sealing-temperature copolyamides for optimized packaging performance.

Low curling films

High strength films

Recyclable

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter