Polyamide 6 and high quality copolyamides for cast film extrusion

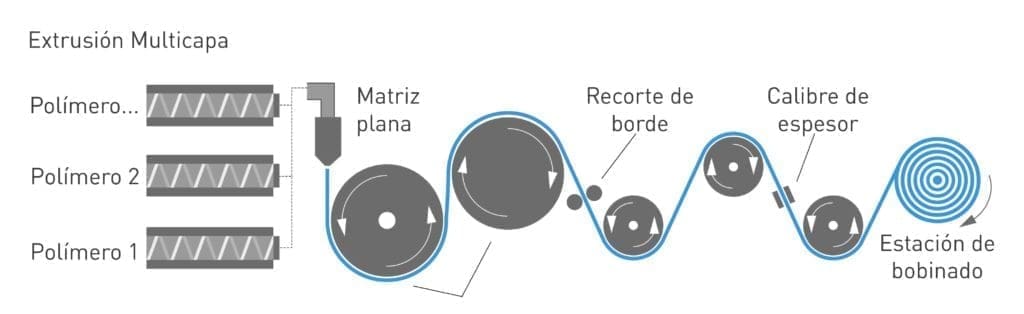

Cast extrusion is a continuous operation of melting one or several polymers through a die to form a film of between 20 and 200μm that will pass through different rollers with different functions (cooling, finishing, etc.) to finally be wound on a reel.

Promyde® offers a wide range of polyamide 6 polymers specially designed for cast film extrusion. Our products are suitable for all cast film processing technologies, both in monolayer and multilayer film structures.

Promyde’s PA6 grades have a high barrier to oxygen and other gases, aromas and flavors. They offer thermal stability, thermoformability and compatibility with other materials used in coextrusion and lamination.

Our range of Promyde Polyamide 6 for cast film extrusion offers extremely stable high quality and excellent processing with the lowest moisture and free monomer content in the market.

WIDE RANGE OF PA6 FOR CAST FILM EXTRUSION

Promyde offers a wide variety of viscosities from 3.3 to 4.0 with different additive packages depending on the requirements of the final application. Our catalog includes products with lubricant, nucleating and slip agents.

Properties of polyamide 6 for cast films

- Low moisture content & monomer.

- Improved barrier to gases (O2, CO2…), aromas and chemicals.

- Availability of grades with increased CO2 permeability.

- Good optical properties, extremely transparent grades.

- Special grades with sealing properties.

- Reduced neck-in.

- Grades available with low curling.

- High temperature HT resistance available for sterilization treatments.

Properties of polyamide 6 for cast films

- Low moisture content & monomer.

- Improved gas barrier (O2, CO2,…) aromas and chemicals.

- Availability of grades with increased CO2 permeability.

- Availability of grades with increased CO2 permeability.

- Special grades with sealing properties.

- Reduced neck-in.

- Grades available with low curling.

- High temperature HT resistance, available for sterilization treatments.

Download our catalogues

Promyde - Film

Solutions

Improved transparency

NUREL has modified PA6 crystallization to offer a range of transparent, strong, and durable materials, ideal for injected parts requiring high transparency.

Barrier solutions

Films for sealing

Active packaging

Active packaging technology incorporates active ingredients encapsulated in the polymer to provide antioxidant and antimicrobial properties, extending the shelf life of packaged foods.

Low curling films

Antiviral solutions

Applicable to all types of polymers, VI_SAFE minimizes the risk of virus transmission by contact with surfaces.

Recyclable

Recycled

Biobased and Biocircular

BIODEGRADABLE

MARKETS

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter