High Barrier Copolyamides

Copolyamides

Our R&D department has developed a range of copolyamides that complements the functionality of conventional PA6, providing solutions that are highly demanded by the packaging industry:

- Deep thermoforming solutions

- Polyamides that remove curling in asymmetrical structures

- Low temperature sealable polyamides

- High puncture and tear resistance

- Oxygen barrier solutions

- Polyamides with high transparency that maintain their properties after pasteurization and retort

- Vacuum packaging shrink film

Other sustainable polyamide solutions

Barrier solutions

Films for sealing

Low curling films

Recyclable

Biobased and Biocircular

Applications

Deep thermoforming

NUREL offers a wide selection of polyamides and copolyamides designed for deep thermoforming packaging, with a focus on providing superior barrier properties and puncture resistance to effectively extend the shelf life of food products, thus contributing to the reduction of food waste. This type of packaging is particularly suitable for the preservation of large portions of fresh meat and whole cheeses.

Pasteurized and retort packaging

These containers are designed to withstand pasteurization and retorting processes, which are food preservation methods involving high temperatures and pressures, for which our latest generation copolyamides are the ideal material.

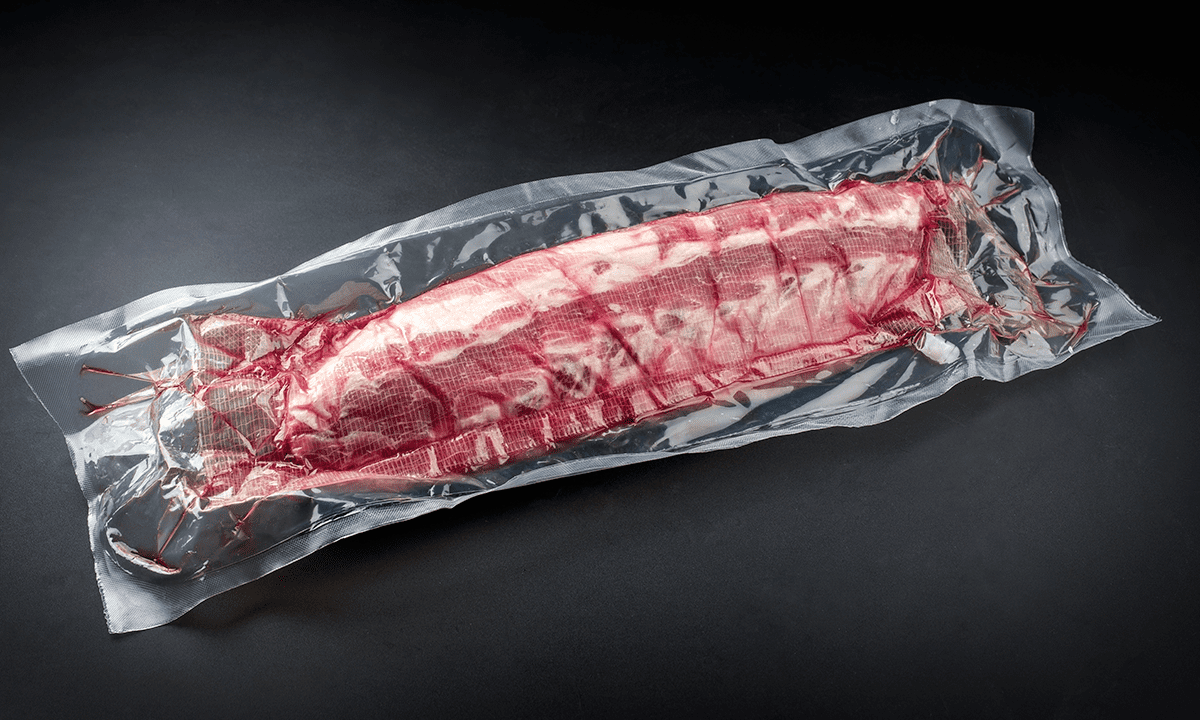

VACUUM PACKAGING BAGS

Polyamide (PA) vacuum bags are extensively used for vacuum-sealing fresh meat, fish, vegetables, cheese and ready-to-eat meals. This packaging solution significantly extends product shelf life by preventing the growth of spoilage-causing microorganisms.

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter