POLYAMIDES AND BIOPOLYMERS WITH RESULTS EXCEEDING 99% ANTIVIRAL EFFICACY

The New England Journal of Medicine has published a study evaluating the stability of SARS-CoV-2 on different surfaces, determining a prevalence of up to 72h on surfaces such as plastic.

NUREL, after months of research and development, has come up with a solution to reduce surface viruses quickly and safely.

VI_SAFE is NUREL’s new antiviral technology that is applicable to all types of polymers and biopolymers for extrusion and injection moulding.

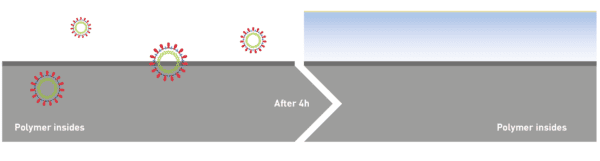

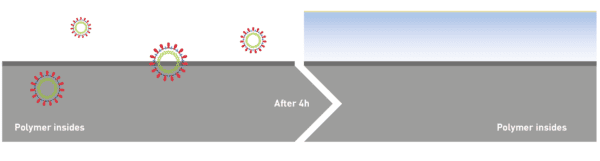

VI_SAFE deactivates the virus and avoids possible transmission by contact with infected surfaces. Surfaces and packaging manufactured with VI_SAFE have an intrinsic antiviral activity and performs a high durability.

VI_SAFE has been tested under the ISO 21702 by independent labs achieving a 99% infectivity reduction.

From now on, sanitary bags and containers, shopping trolleys, seats in public transport or switches, will be safer thanks to VI_SAFE.

Advantages of NUREL's antiviral polyamide solutions

The New England Journal of Medicine has published a study evaluating the stability of SARS-CoV-2 on different surfaces, determining a prevalence of up to 72h on surfaces such as plastic.

NUREL, after months of research and development, has come up with a solution to reduce surface viruses quickly and safely.

VI_SAFE is NUREL’s new antiviral technology that is applicable to all types of polymers and biopolymers for extrusion and injection moulding.

VI_SAFE deactivates the virus and avoids possible transmission by contact with infected surfaces. Surfaces and packaging manufactured with VI_SAFE have an intrinsic antiviral activity and performs a high durability.

VI_SAFE has been tested under the ISO 21702 by independent labs achieving a 99% infectivity reduction.

Advantages of NUREL's antiviral polyamide solutions

The New England Journal of Medicine has published a study evaluating the stability of SARS-CoV-2 on different surfaces, determining a prevalence of up to 72h on surfaces such as plastic.

NUREL, after months of research and development, has come up with a solution to reduce surface viruses quickly and safely.

VI_SAFE is NUREL’s new antiviral technology that is applicable to all types of polymers and biopolymers for extrusion and injection moulding.

VI_SAFE deactivates the virus and avoids possible transmission by contact with infected surfaces. Surfaces and packaging manufactured with VI_SAFE have an intrinsic antiviral activity and performs a high durability.

VI_SAFE has been tested under the ISO 21702 by independent labs achieving a 99% infectivity reduction.

Applications of antiviral films made with PA6

In different activities of our daily life, we are in contact with surfaces and objects, for example in public transport, schools and hospitals, at work, etc.

Thanks to NUREL’s VI_SAFE solution, all these surfaces can be more hygienic, providing greater protection against bacterial contamination.

Related markets

Packaging

Polyamides are widely used in the packaging industry due to their excellent mechanical strength and barrier properties, as well as their ability to deliver a premium finish with high gloss and transparency.

INDUSTRIAL

The industrial sector demands high-performance materials to meet stringent standards of efficiency, durability and strength. Our range of engineering polymers and recycled technical composites offer high-value solutions for the manufacture of industrial machinery and precision components.

Electrical and electronic

NUREL PA, PBT, PET, PBT/PET and PP compounds are present in parts and components of electrical and household appliances. Parts molded with Promyde®, Proxylene®, Olexene®, or Recomyde® can be found in food processors, white goods such as refrigerators, washing machines and dryers.

Consumer goods

Engineering plastics are used in a multitude of applications that reach the end consumer. Household appliances, tools, electronic devices, sports equipment and kitchen utensils all feature materials made of NUREL polyamide and PBT compounds.

OTHERS SOLUTIONS

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter