ADVANCED PA6 AND PBT SOLUTIONS FOR DEMANDING HYDROLYSIS CONDITIONS

Hydrolysis is a chemical reaction in which polymers are broken down by the action of water. This reaction leads to the breakage of molecular chains, a loss of molecular weight and a loss of polymer properties, especially toughness.

Hydrolysis is a slow process at room temperature, but can be rapid at high temperatures. This is an irreversible process, as even drying the material will not restore its original properties.

Some applications require materials with special properties to resist hydrolysis, such as tanks, pipes and ducts, where the polymer is in contact with hot water, steam or water-glycol mixtures.

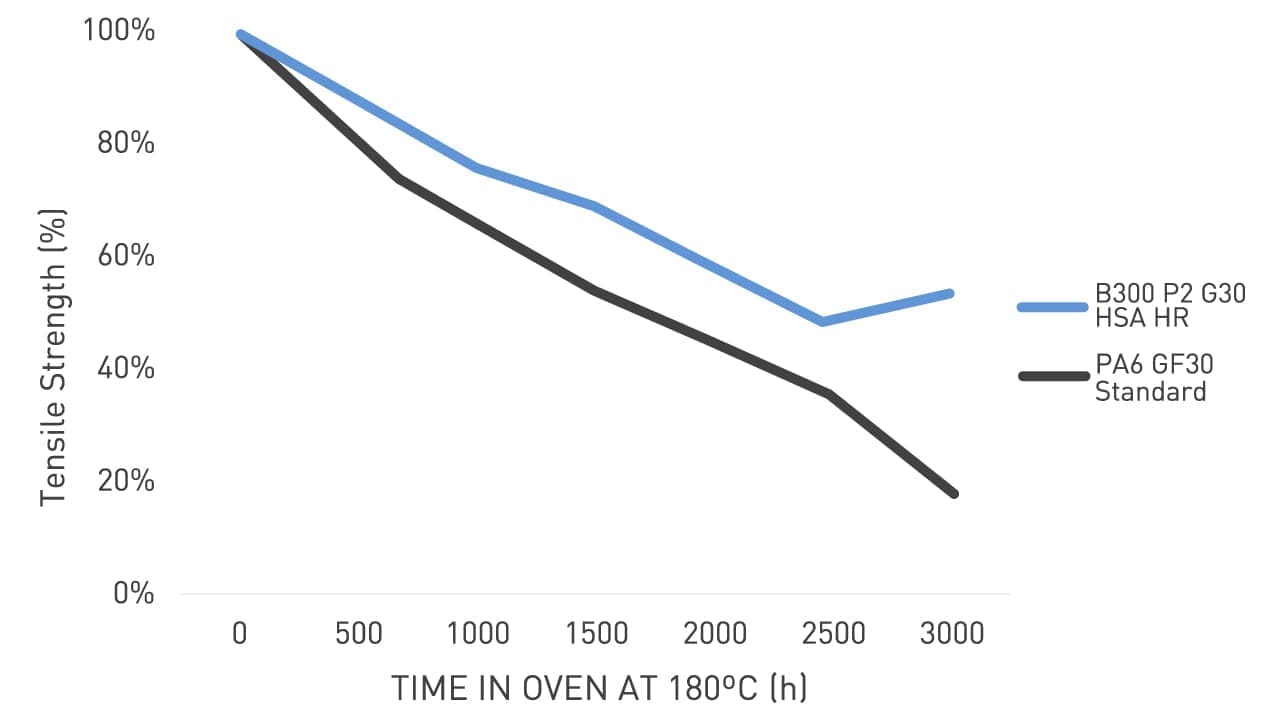

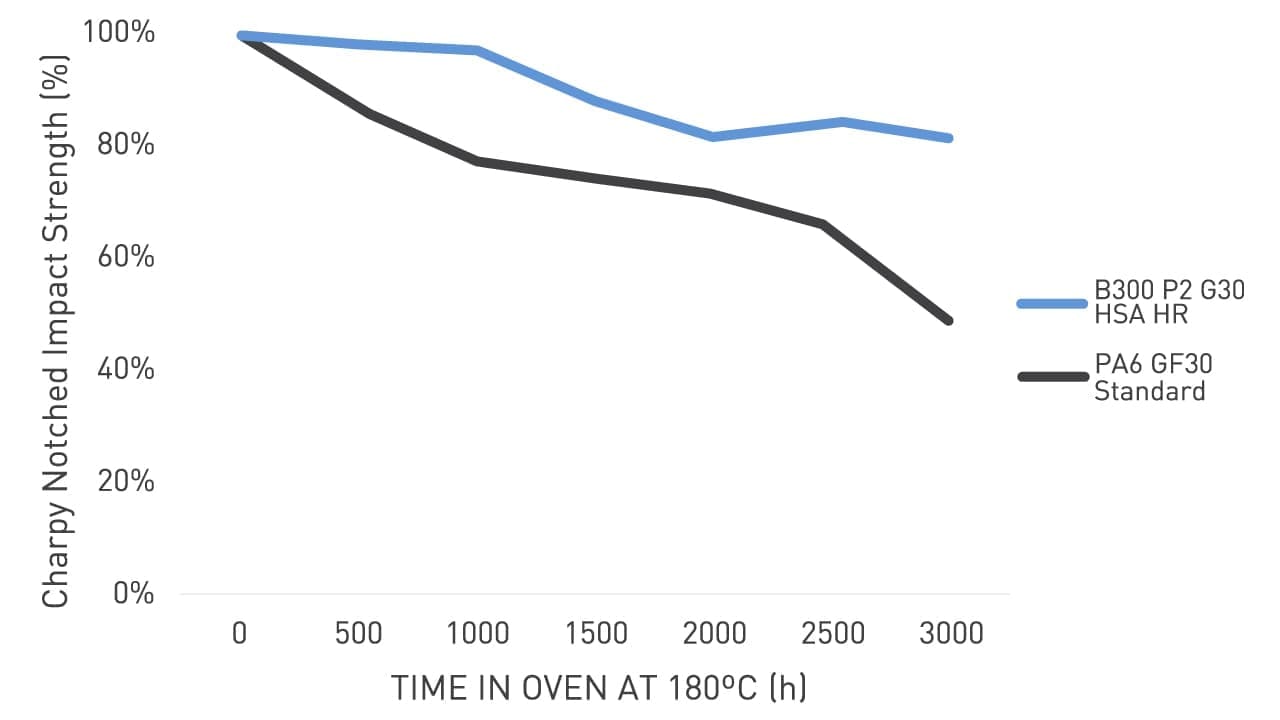

PROMYDE® HSA HR: PA6 with resistance to HYDROLISIS and heat stabilized

NUREL has recently developed PROMYDE® HSA HR, a range of special glass fiber reinforced PA6 grades specially designed for parts requiring extreme hydrolysis resistance.

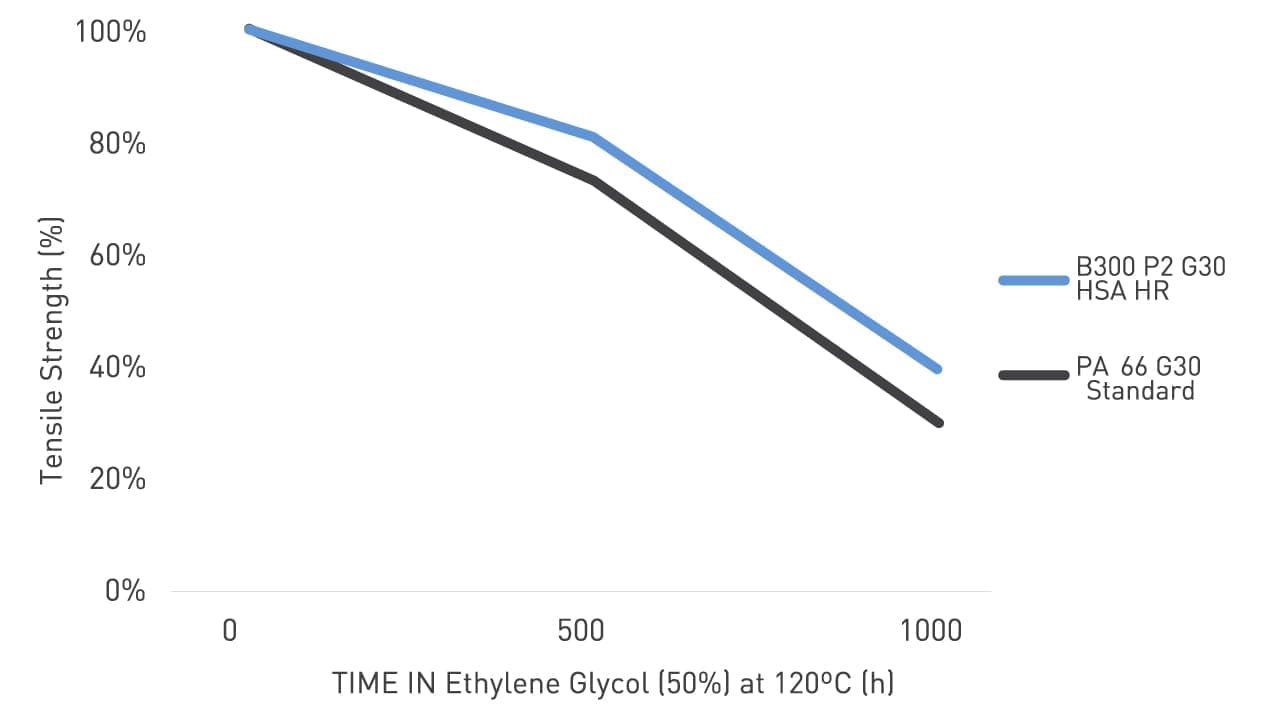

PROMYDE® HSA HR PA6 grades show significantly improved ageing properties and hydrolysis resistance compared to existing PA6 and PA66 alternatives.

After a comparative test, our PA6 HSA HR grades have been shown to outperform even special hydrolysis resistance PA66 grades in durability.

NEW HYDROLYSIS RESISTANT PROXYLENE® PBT TYPES

The contact with water in polyesters, even in the form of atmospheric moisture, causes the hydrolytic breakdown of the polymer chains and, consequently, the weakening of the material, especially at high temperatures.

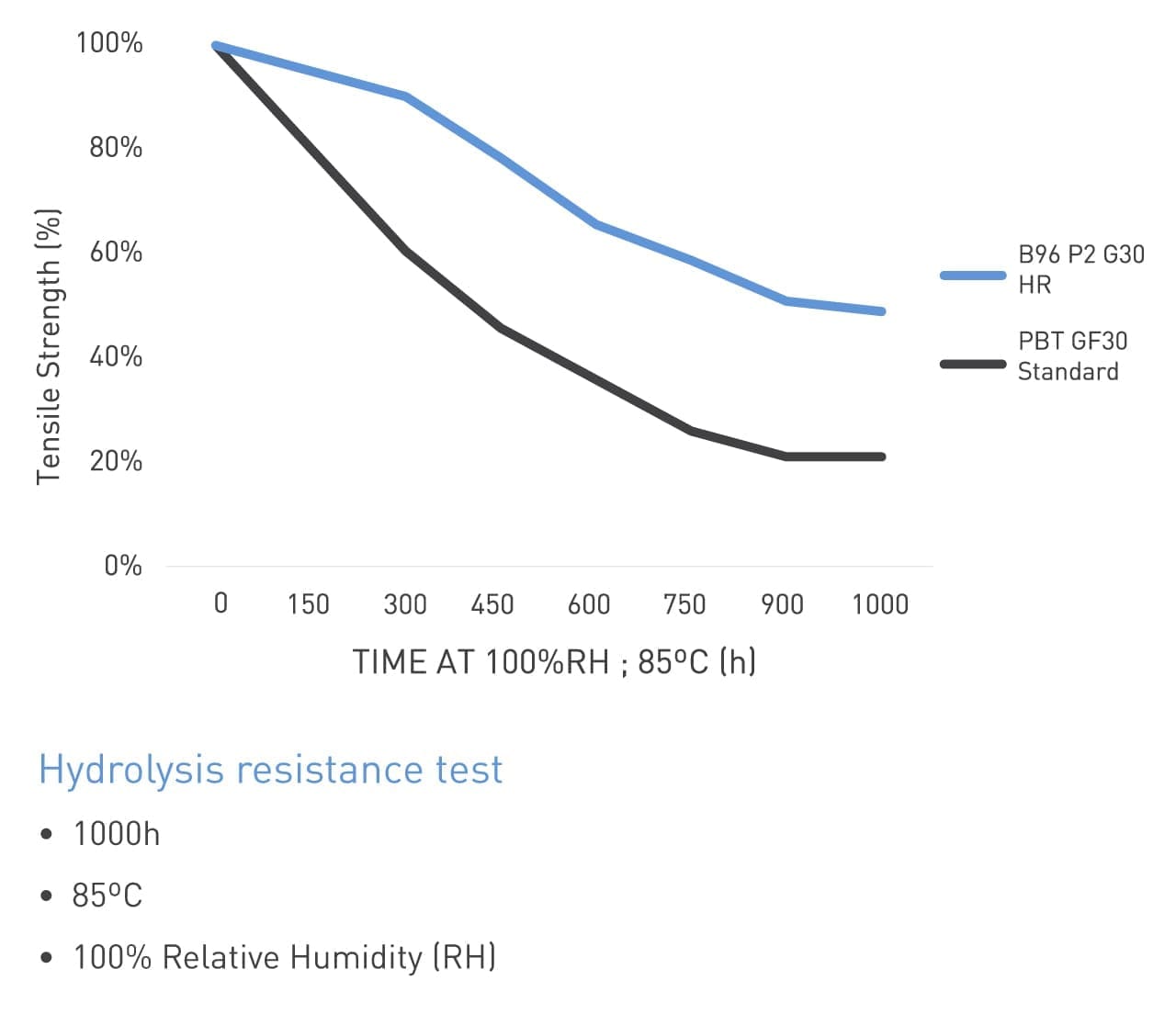

PROXYLENE® HR PBT incorporates additives that significantly reduce hydrolytic degradation, considerably extending the service life of the final product. The PROXYLENE® HR PBT range offers exceptional resistance to prolonged exposure to water at high temperatures.

PROXYLENE® HR PBT is available in unreinforced grades and with 15% and 30% glass fibre reinforcement.

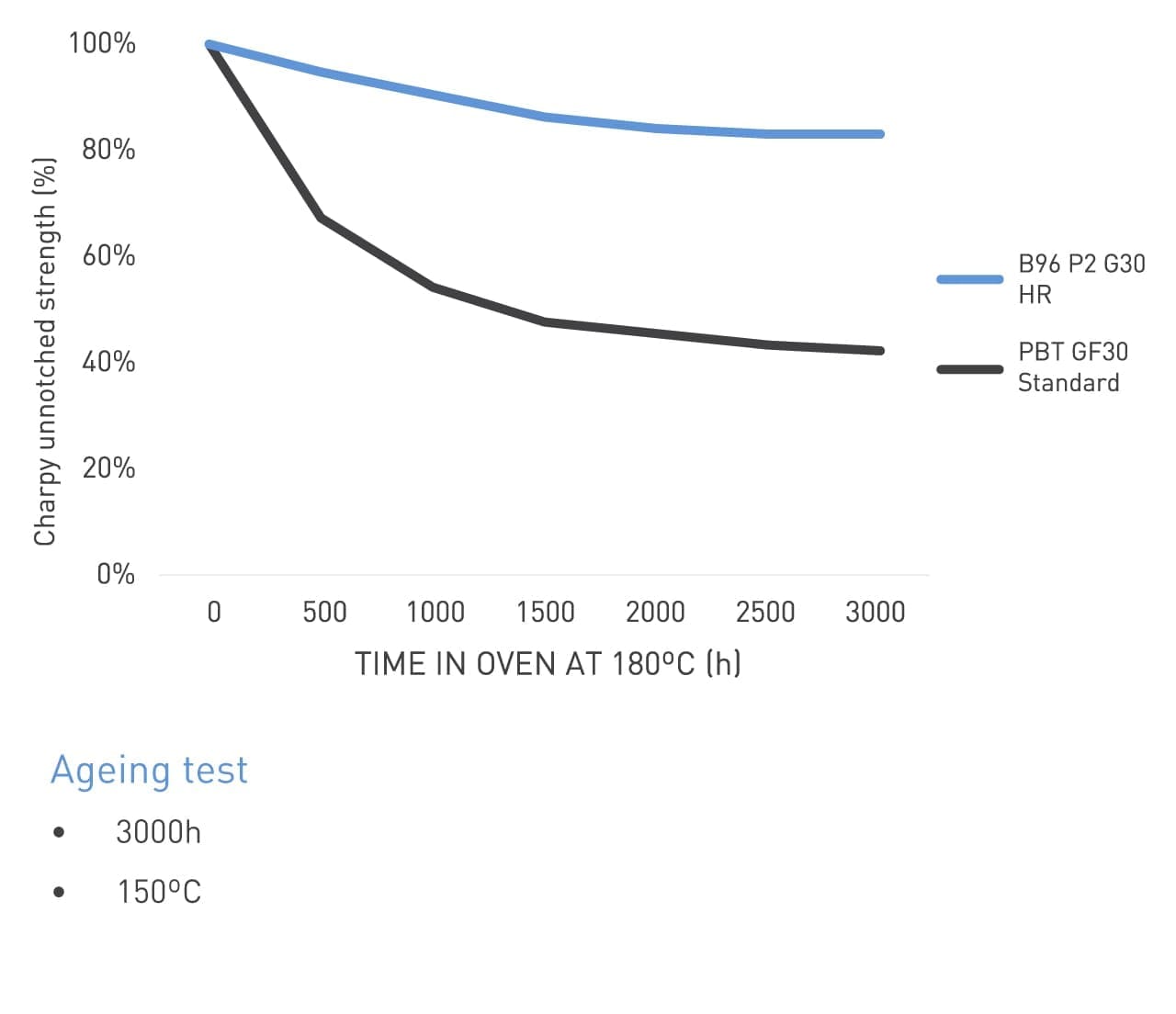

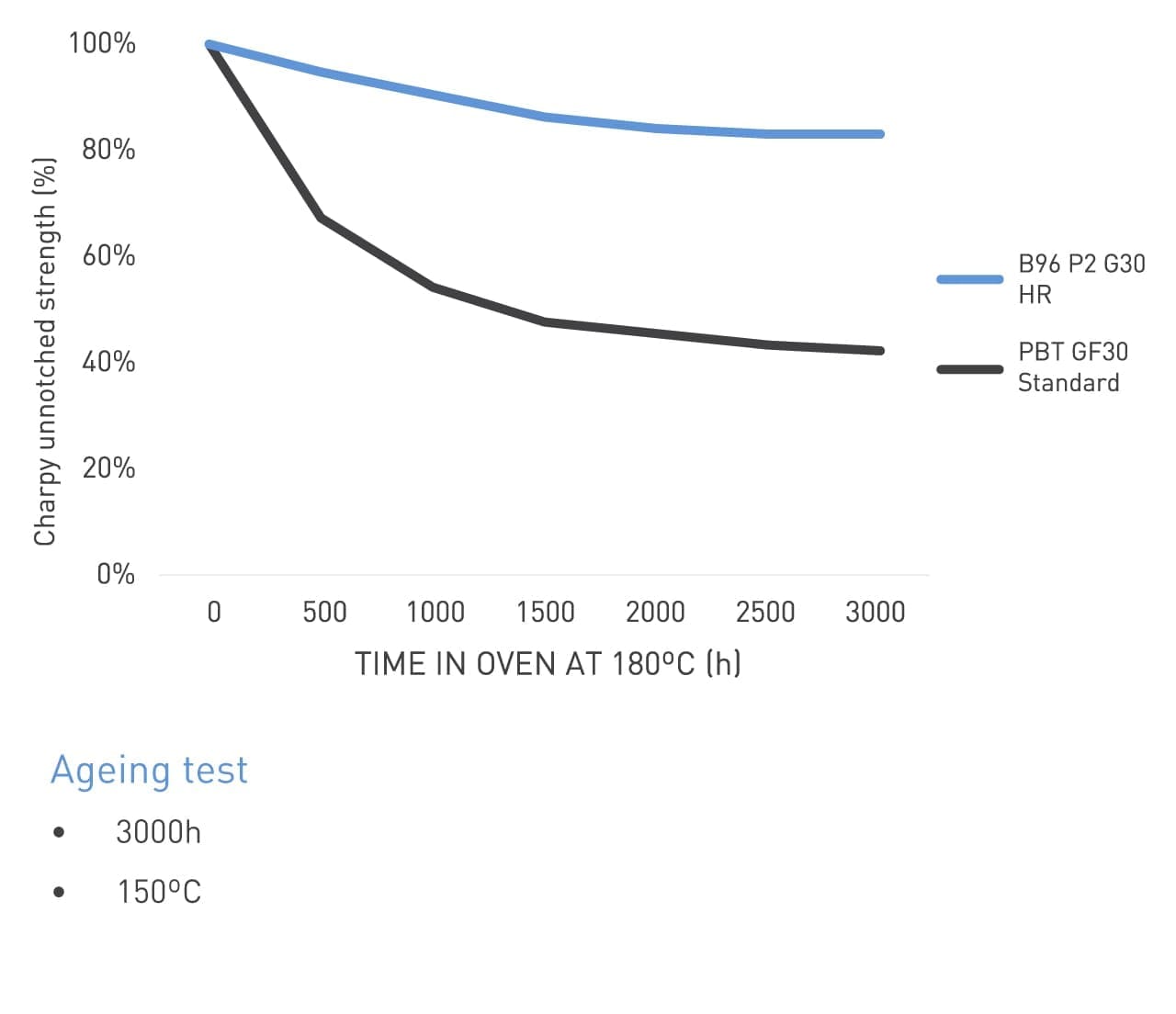

Proxylene® B96 P2 G30 HR not only offers excellent resistance to hydrolysis, but also withstands high temperatures, making it an ideal material for continuous-use applications where thermal and chemical stability are essential.

NEW HYDROLYSIS RESISTANT TERYLENE PBT

PROXYLENE HR PBT polymers offer very high resistance of the PBT polymer to prolonged exposure to high temperature water. Contact with water in polyesters, even in the form of atmospheric humidity, causes hydrolytic breakage of the polymer chains and thus weakening of the material, especially at elevated temperatures.

PROXYLENE HR PBT incorpora aditivos que retrasan en gran medida la degradación hidrolítica, prolongando considerablemente la vida útil del producto final. PROXYLENE HR PBT son grados de PBT no reforzados para el moldeo por inyección y la extrusión.

PROXYLENE B96 P2 G30 HR, after an extreme hydrolysis resistance test (100% RH, 85ºC), and an aging test (3000h, 150ºC), showed a relevant effect in continuous use.

Applications

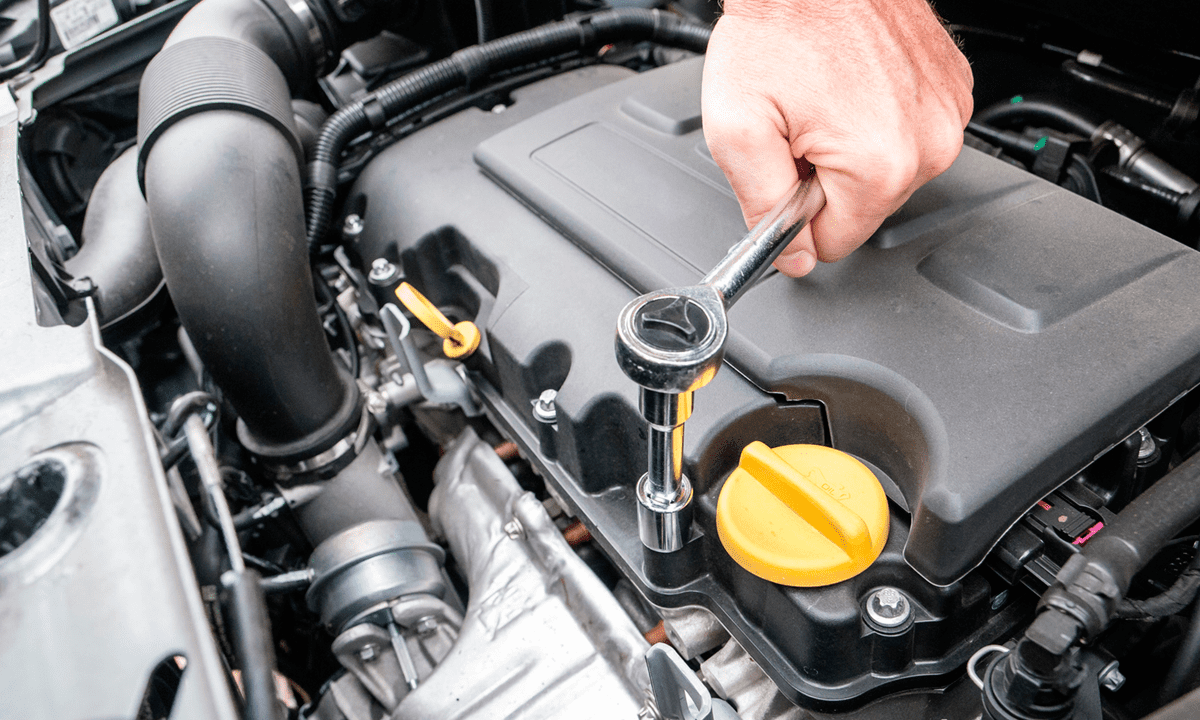

Underhood Applications

The Promyde® range of materials provides solutions for all types of under-hood applications requiring high temperature stability and hydrolysis resistance, while maintaining their mechanical properties.

Electric vehicle

NUREL has developed engineered polymers for electric vehicles, improving autonomy, safety and sustainability. Our range of compounds, including PA6, PA66, PBT, PET, PP and PA, recycled PET and PP, offers solutions for interior, exterior, aesthetic finishes and metal replacement components, helping to reduce vehicle weight and ensuring high performance.

TANKS AND RESERVOIRS

Promyde PA6 blown extrusion grades with a viscosity of 5.0 provide improved mechanical properties and increased flow resistance in the molten state.

RELATED MARKETS

MOBILITY AND AUTOMOTIVE

The mobility sector has always been a leader in mechanical innovation and process optimization. At NUREL, we support this evolution with our range of engineering polymers - PA6, PA66, PBT, PET and PP - designed to respond to the industry's demand for lighter, more sustainable and efficient solutions.

INDUSTRIAL

The industrial sector demands high-performance materials to meet stringent standards of efficiency, durability and strength. Our range of engineering polymers and recycled technical composites offer high-value solutions for the manufacture of industrial machinery and precision components.

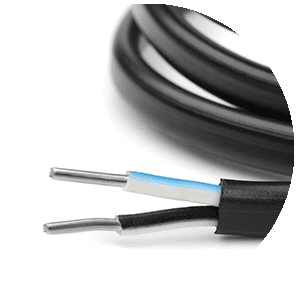

Cables and Pipes

Promyde® PA and Proxylene® PBT polymers for UL 83-certified cables such as copper building wire, PVC Nylon tray cable, THHN cable and THWN cable, fiber optic cable, as well as tubes and pipes for cable management systems.

OTHERS SOLUTIONS

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter