CAST AND THERMOFORMING

COMPOSTABLE BIOPOLYMERS FOR FILM EXTRUSION

INZEA ® replaces petroleum-based plastics for the production of thermoformed trays and cast film in a sustainable manner. Conventional polymers, such as PE, PP or PS, have traditionally been used by industry to produce packaging and other plastic films from fossil resources which, in many cases, due to multi-material and multi-layer blends, cannot be easily recycled.

INZEA’s range of biopolymers offers bio-based and compostable solutions for cast film extrusion. Our products can be processed on conventional PE and PP extrusion lines. INZEA offers equivalent properties to polymers from non-renewable sources, thus obtaining mono or multilayer packaging for sustainable packaging applications.

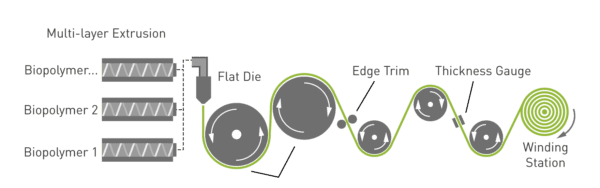

Cast film extrusion with INZEA biopolymers

Cast film extrusion is a continuous operation that is based on melting one or more polymers through a slot die to form a thin film that is conveyed to successive rollers with different functions, such as cooling or finishing, and finally wound onto a reel. When processing INZEA cast extrusion grades, a melt temperature of 150°C and a cast temperature of 30°C should be applied.

Compared to blown film, cast film is more suitable for thermoforming applications. Typical cast film thickness ranges from 20-400 μm and widths of 400-3000 mm.

THERMOFORMED COMPOSTABLE PACKAGING

Conventional polymers from non-renewable sources such as PET or PP can now be replaced by INZEA, a sustainable alternative that provides the same technical properties.

According to EU regulation EN13432, cast films produced with our INZEA biopolymers are compostable and can obtain OK compost INDUSTRIAL certification.

Key benefits

- Barrier properties for food packaging

- Available transparent grades

- Suitable for food contact

- OK compost INDUSTRIAL

- The perfect solution for thermoforming

THERMOFORMED PACKAGING MADE FROM INZEA BIOPOLYMERS IS COMPOSTABLE.

WHAT IS INZEA

The world is changing and the plastics industry has to adapt to a new situation where sustainability is a priority for governments, businesses and consumers. INZEA® is our response to our customers’ demand for more sustainable plastic materials.

INZEA is a range of biopolymers which can replace traditional plastics in different applications such as bags, mono-use items and packaging, with the advantage of being biodegradable and compostable.

INZEA product range is obtained from renewable sources and is designed to return to nature by different disposal methods like industrial & home composting, or by biodegradation in different environments.

APLICATIONS

Trays

INZEA® offers biodegradable and compostable solutions for food contact trays for take away and cooked product packaging. Thermoformed trays, film-coated cellulose trays, paper-like and laminated trays can now be managed together with organic waste.

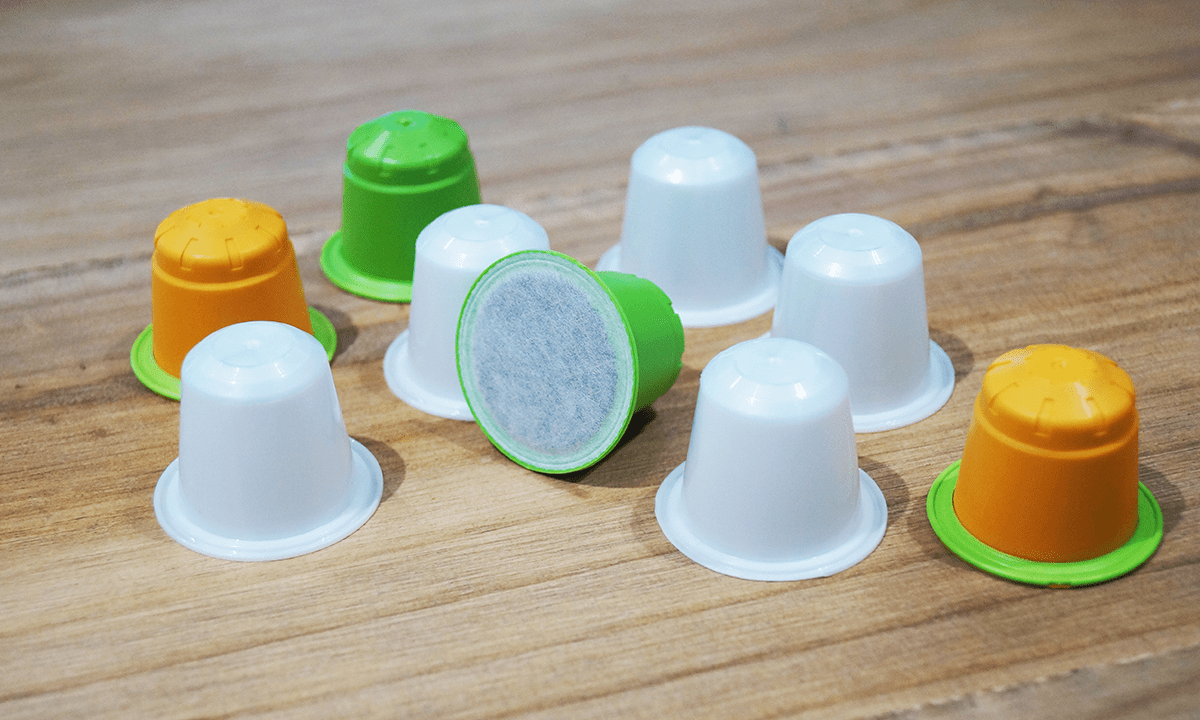

Coffee capsules

INZEA ® has grades suitable for the manufacture of coffee capsules that meet the required mechanical, thermal resistance and barrier requirements.

Catering materials

INZEA offers solutions for biodegradable and compostable cutlery, plates, cups and straws that replace those made from conventional plastics.

Boxes for fresh and cooked food

INZEA offers solutions for the manufacturing of clamshells and thermoformed boxes for food.

DISCLAIMER: Finished product made of certified raw materials or components does not automatically comply with the requirements of the relevant certification scheme.

Want to stay updated on the latest on NUREL Biopolymers?

Subscribe to the Newsletter