SOLUTIONS THAT ENABLE RECYCLING OF CONTAINERS

Much of the food packaging cannot be recycled in existing recycling systems. This is especially true in the case of barrier structures that are composed of several materials. Obtaining flexible, barrier and recyclable packaging requires a combination of packaging redesign, innovation in materials and transformation processes, as well as optimization and development of new recycling technologies.

NUREL offers the following solutions:

RECYCLABLE SINGLE MATERIAL POLYAMIDE SOLUTIONS

Thanks to the low sealing temperature of Promyde® copolyamides, it is possible to dispense with polyethylene or polypropylene in multilayer structures and achieve a recyclable, lighter, single-material package while maintaining high performance. Promyde monomaterial 100% polyamide structures can be recycled in a closed cycle through the recovery and reprocessing of waste generated during the manufacture of packaging.

RECYCLABILITY OF LDPE/PA STRUCTURES

Polyamide is widely used in multilayer structures to improve oxygen barrier, mechanical properties (tear and puncture resistance), thermoforming and thermal resistance (pasteurization and sterilization processes). Thanks to the high performance of our copolyamide Promyde BF540, it is possible to achieve structures with a very low PA content (<30%), which is accepted in the polyethylene recycling stream.

In addition, Promyde BF740, a copolyamide with better oxygen barriers than conventional polyamide, further reduces the percentage of PA in the structure, facilitating its recyclability in the PE stream.

RECYCLING OF ULTRA-HIGH BARRIER PET-BASED FILMS

NUREL has developed Enoxite®, an ultra-high barrier water soluble solution, which allows the delamination of multilayer films.

Multilayer PET/ENOXITE/PET structures show a barrier similar to those proposed with EVOH, with the added advantage of dissolving in hot water baths present in PET recycling plants, thus allowing higher quality recycling to be obtained.

RECYCLABILITY OF POLYETHYLENE BARRIER FILMS

Enoxite, our ultra-barrier solution, allows the manufacturing of PE/Enoxite/PE films with a lower % of barrier material, thanks to its high performance.

SEPARATION OF MULTILAYER STRUCTURES

Multi-material packaging has a complex recyclability. Enoxite®, a water-soluble barrier solution, facilitates the separation of the different layers of multilayer films for subsequent recycling. NUREL has Enoxite grades soluble in water at different temperatures: from 20 to 60ºC.

APLICATIONS

Stand-up pouches

NUREL offers a complete range of Polyamide 6, Copolyamides and Ultra-High barrier materials for Doypacks. PA-based film materials not only help extend the shelf life of packaged food but also contribute to reducing plastic usage. Promyde polyamides offer excellent mechanical and barrier properties while providing an appealing packaging finish, thanks to their glossy appearance.

Vacuum Packaging

PA vacuum bags are commonly used to vacuum pack meats, fish, vegetables, cheese and prepared foods. Vacuum sealing helps to extend the shelf life of these products by preventing the growth of microorganisms that cause spoilage.

Deep thermoforming

NUREL offers a wide selection of polyamides and copolyamides designed for deep thermoforming packaging, with a focus on providing superior barrier properties and puncture resistance to effectively extend the shelf life of food products, thus contributing to the reduction of food waste. This type of packaging is particularly suitable for the preservation of large portions of fresh meat and whole cheeses.

Cheese packaging

Cheese packaging is essential to guarantee the quality, safety, and freshness of the product. It must meet a series of requirements to protect the cheese from oxidation, dehydration, and preserve its maturation process. NUREL offers solutions that adapt to these requirements by providing packaging with barrier properties and oxygen permeability.

Pasteurized and retort packaging

These containers are designed to withstand pasteurization and retorting processes, which are food preservation methods involving high temperatures and pressures, for which our latest generation copolyamides are the ideal material.

Thermoformed lids and trays

The Promyde® range of polyamides and copolyamides offers a combination of mechanical strength, moisture barrier and sealing properties that are optimal for the manufacture of thermoformed lids and trays. In addition, Enoxite®, thanks to its ultra-barrier properties, helps to preserve the freshness and quality of these foods for a longer period of time.

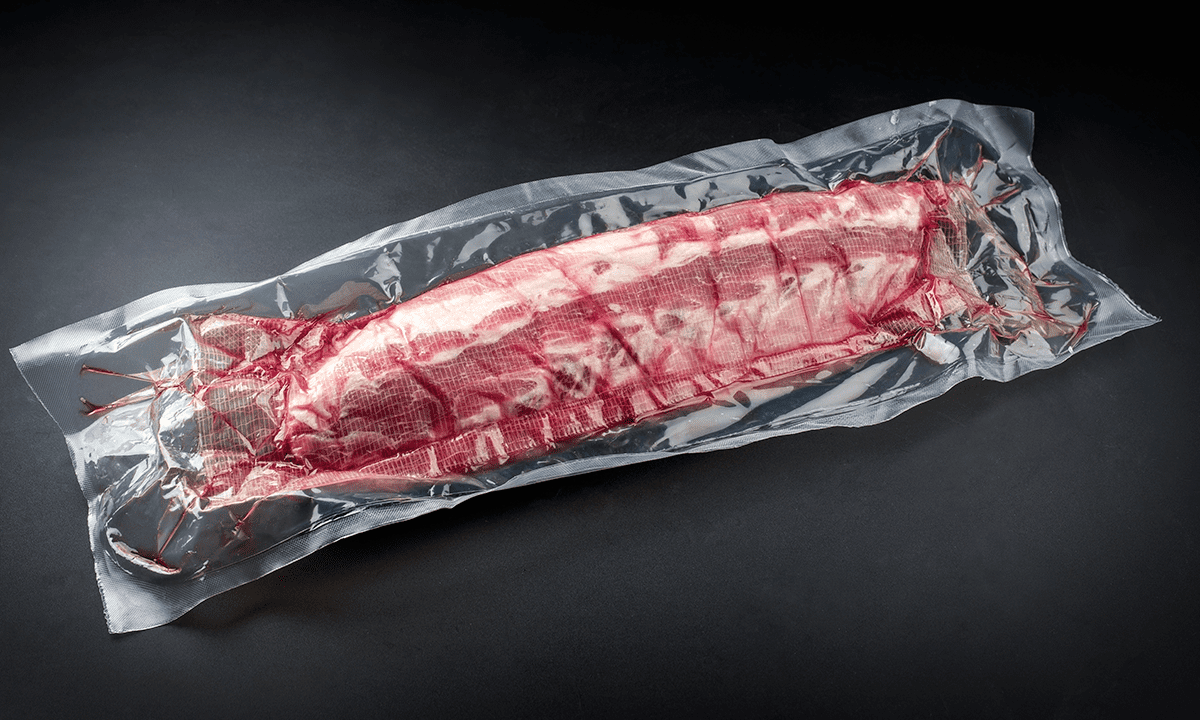

Meat and bone-in meat packaging

Packaging for sharp-edged foods requires high puncture resistance, flexibility, moisture barrier, transparency, and an attractive gloss. NUREL offers a range of special copolyamides and polymers with high oxygen barrier properties for the manufacturing of vacuum bags and thermoformed packaging for meat.

Skin Packaging

Skin packaging is gaining popularity due to its lightweight and visually appealing design, as well as its superior technical performance. NUREL provides specially formulated copolyamides that exhibit exceptional strength, sealing capabilities, barrier properties, and unmatched glossiness.

Fish and seafood packaging

NUREL offers a variety of polyamides, copolyamides and barrier polymers specifically designed for fresh fish and seafood packaging. These materials provide an effective barrier, ensuring optimum product protection and enhancing the visual appeal of the packaging.

Related markets

Packaging

Polyamides are used in the packaging industry for their good mechanical properties, barrier properties and for providing a quality finish due to their high gloss and transparency.

OTHERS SOLUTIONS

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter