Polyamide 6 for blown film extrusion

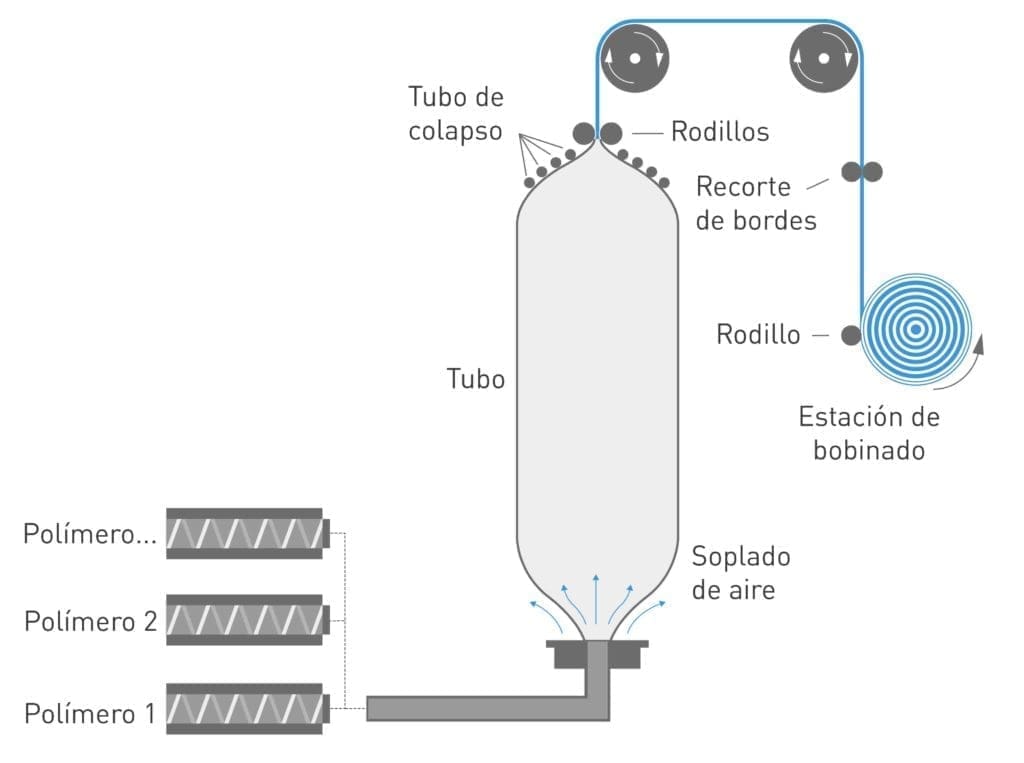

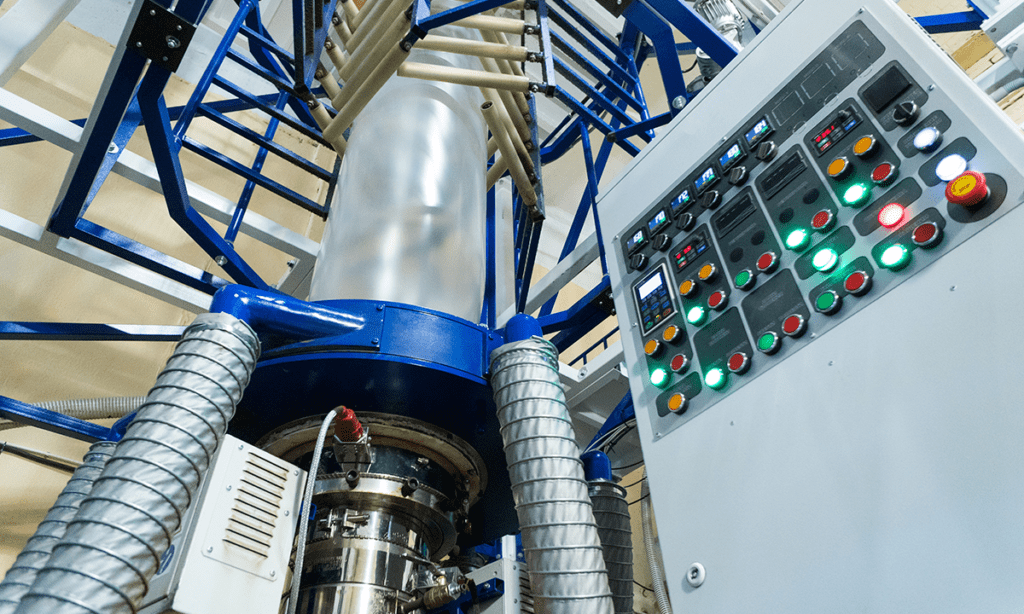

Blown film extrusion is the continuous process of casting one or more polymers in a circular die to form a hollow tube. This tube expands with air, cools and flattens, and finally coils up.

Promyde® offers a wide range of polyamide 6 polymers specially designed for blown film extrusion. Our products are suitable for all blown film processing technologies, both in monolayer and multilayer film structures and with air or water cooling systems.

NUREL’s polyamide 6 has high barrier properties, offering thermal stability and high compatibility with other materials used in coextrusion and lamination.

Promyde has developed a range of polyamides for extrusion blow film that offers high quality standards with simple processing due to its low moisture and monomer content.

WIDE RANGE OF PA6 FOR EXTRUSION BLOW MOLDING

Promyde has a wide range of viscosities, ranging from 3.3 to 4.0, including different additive packages depending on the needs of the final application. In addition, we offer various products with lubricant, nucleating and slip agents.

SPECIFIC PROPERTIES FOR BLOWN FILM

- Low moisture content & monomer.

- Improved gas barrier (O2, CO2,…) aromas and chemicals.

- Availability of grades with increased CO2 permeability.

- Availability of grades with increased CO2 permeability.

- Special grades with sealing properties.

- Reduced neck-in.

- Grades available with low curling.

- High temperature HT resistance, available for sterilization treatments.

SPECIFIC PROPERTIES FOR BLOWN FILM

- Low moisture content & monomer.

- Improved gas barrier (O2, CO2,…) aromas and chemicals.

- Availability of grades with increased CO2 permeability.

- Availability of grades with increased CO2 permeability.

- Special grades with sealing properties.

- Reduced neck-in.

- Grades available with low curling.

- High temperature HT resistance, available for sterilization treatments.

Download our catalogues

Promyde - Film

Solutions

Barrier solutions

Films for sealing

Low curling films

MARKETS

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter